Stainless Steel 304/304L Buttweld Fittings Manufacturers, Suppliers and Stockist – UNS S30400/UNS S30403, 1.4307/1.4301 Pipe Fittings

- Metallica is engaged in manufacturing stainless steel 304/304L buttweld pipe fittings, and executes supplies both from stock and production. Our stock consists of buttweld pipe fittings in outside diameters ranging from 1/2” – 36” NB, schedule from Sch5s to SchXXS. Metallica specializes in manufacturing elbows, tee, reducer, caps, crosses, stub ends, etc conforming to ASME, ANSI, and DIN standard. We also produce custom size pipe fittings made according to drawings from our clients. Our products are widely used in oil & gas, petrochemical, refineries, power plant, shipbuilding, metallurgy, paper making and other industries.

- We are considered one of the biggest stainless steel 304/304L buttweld fittings supplier and manufacturer, with over 250 customers in India and overseas. We are bulk sellers and exporters of stainless steel 304/304L buttweld pipe fittings, seamless pipes, welded pipes, plates, fittings and flanges from our factory in India, and are able to give you the best price and quality just in time.

- With minimum yield strength of 170 Mpa, minimum tensile strength of 485 Mpa, and with minimum Elongation of 35%, stainless steel 304L buttwelding fittings are widely used for engineering and general purpose applications. In comparison, the ASTM specifications require minimum yield strength of 205 Mpa, minimum tensile strength of 515 Mpa, and minimum Elongation of 35% for stainless steel 304 buttweld fittings. Stainless steel 304/304L buttwelding fittings also have good heat resistant and corrosion resistant properties.

- Stainless steel 304 (SS 304) is the most basic stainless steel known as 18-8 grade with higher chromium and low carbon content. The low carbon content restricts carbide precipitation during welding as well as minimizes its susceptibility to intergranular corrosion. Stainless steel 304L (SS304L) is an extra low-carbon variation of SS304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding. Both SS304 and SS304L have excellent resistance to a wide range of atmospheric, chemical and petrochemical, and food industry corrosions. Usually, they can be used in applications with the maximum temperature of 1650°F[900°C] exhibiting good oxidation resistance.

- A butt weld pipe fitting is a type of pipe fitting, which is designed to be welded on site to connect pipes together. Welding of a buttweld pipe fitting to pipes or other fittings is generally done to allow change in direction of the piping system. Buttweld fittings are generally identified or inquired in nominal pipe sizes with specified pipe schedule. Buttweld fitting’s dimensions and tolerances are defined as per ASME B16.9 standard. All buttweld pipe fittings have beveled ends as per ASME B16.25 standard. This helps create full penetration weld without any extra preparation needed for the butt weld fitting.

- Manufacturing buttweld fittings – A butt weld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dies. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties. Sch 10 fittings are also more common in stainless steel butt weld fitting, while SCH 40 is common for carbon steel butweld fittings.

- Being one of the largest volume buttweld pipe fittings manufacturer and supplier in Mumbai, we can guarantee you the lowest prices. At Metallica Metals, we believe in selling in volume and increasing our customer base across the globe, enabling us to work on low margins. We have an extensive trader network across India, USA, Europe and the Middle East, who buy from us on a regular basis.

- In addition to traders, we have many EPC contractors, companies and end users in various industries as our customers. We are leading buttweld fittings suppliers for various applications ranging from low/medium/high pressure or temperatures.

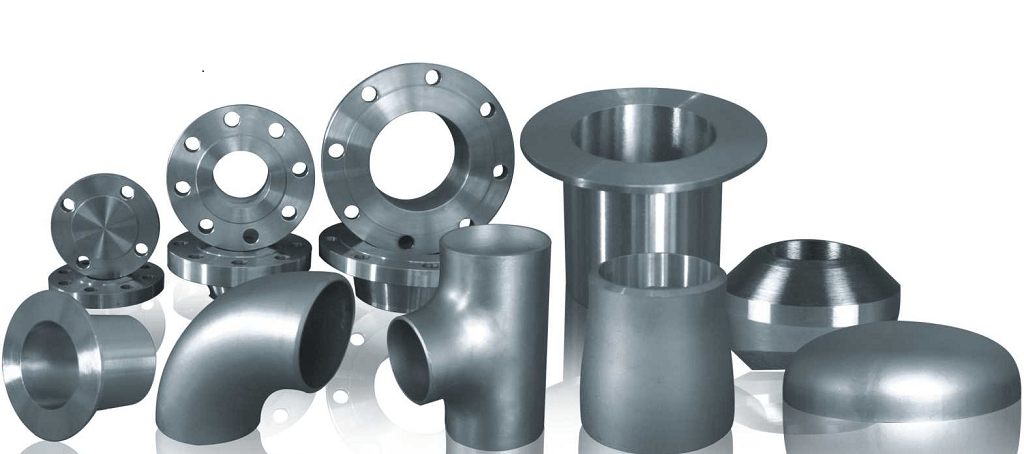

Butt Weld Pipe Fittings Manufacturers and Suppliers

Types of Stainless Steel 304/304L Butt Weld Pipe Fittings

- SS 304 Pipe Elbow – Steel elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends.

- SS 304 Pipe Bend – Pipe bend can be made of variety materials, like carbon steel, alloy steel, stainless steel, low temperature steel or high-performance steel, etc.

- SS 304 Pipe Tee – We can provide seamless tube tees and welding tube tees, which can also be divided into straight tees and reducing tees. Usually, the pipe tees have the same inlet and outlet sizes.

- SS 304 Pipe Cross – A pipe fitting, having four openings in the same place, at right angles to each other. A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or three inlets and one outlet.

- SS 304 End Caps – End Cap, Carbon Steel cap, Stainless Steel Caps, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches. Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- SS 304 Pipe Reducer – Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations.

- SS 304 Stub End – Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End.

- SS 304 Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Stock & Production Range for Stainless Steel 304/304L Buttweld Pipe Fittings (UNS S30400/1.4301, UNS S30403/1.4307)

| Product | Stainless Steel 304/304L Buttweld Pipe Fittings |

| Equivalents | AISI 304, AISI 304L, UNS S30400, UNS S30403, WNR.1.4301/1.4307 |

| Specifications | ASTM A403 WP304/304L |

| Size | 1/2″ NB to 48″ NB |

| Thickness | 0.5mm – 19mm |

| Type | Seamless, Welded, 100% X-Ray Welded |

| Condition | Annealed & Pickled |

| Certification | EN 10204 3.1 |

| Prices | info@metallicametals.com | +918928722715 |

Full Range of Stainless Steel 304/304L Products

| Stainless Steel 304/304L Pipes | Stainless Steel 304/304L Seamless Pipes |

| Stainless Steel 304/304L Welded Pipes | Stainless Steel 304/304L Square/Rectangular Pipes |

| Stainless Steel 304/304L Flanges | Stainless Steel 304/304L Buttweld Fittings |

| Stainless Steel 304/304L Forged Fittings | SS 304/304L Socket Weld Pipe Fittings |

| Stainless Steel 304/304L Threaded Fittings | Stainless Steel 304/304L Fasteners |

| Stainless Steel 304/304L Nuts & Bolts | Stainless Steel 304/304L U Bends & Tubes |

| Stainless Steel 304/304L Valves | Stainless Steel 304/304L Tubes |

| Stainless Steel 304/304L Furnace Tubes | Stainless Steel 304/304L Seamless Tubing |

| SS 304/304L Heat Exchanger Tubes | Stainless Steel 304/304L Large Dia. Pipes |

| Stainless Steel 304/304L Boiler Tubes | SS 304/304L High Pressure Pipes |

| Stainless Steel 304/304L Forgings | SS 304/304L High Temperature Pipes |

| Stainless Steel 304/304L Instrumentation Tubes | Stainless Steel 304/304L Instrumentation Tube Fittings |

| Stainless Steel 304/304L High Pressure Pipe Fittings | Stainless Steel 304/304L Tube Fittings |

| Stainless Steel 304/304L Plate Cut Circles | Stainless Steel 304/304L Forged Rings |

| Stainless Steel 304/304L Blocks for Machining | Stainless Steel 304/304L Round Bar |

| Stainless Steel 304/304L Flat Bars | Stainless Steel 304/304L Angle Bars |

| Stainless Steel 304/304L Rods | Stainless Steel 304/304L Threaded Rods |

| Stainless Steel 304/304L Sheet/Plates | Stainless Steel 304/304L Coils/Strips |

About Buttweld Pipe Fittings

Buttweld fittings (also know as welded pipe fittings) in carbon steel and stainless steel are the joining components that make possible the assembly of valves, pipes and equipment onto the piping system. Butt welded fittings compliment pipe flanges in any piping system and allows;

- Change direction of flow in a piping system

- Connect or joint pipes and equipment

- Provide branches, access and takeoffs for auxiliary equipment

Manufacturing standards are governed under ANSI/ASME B 16.9. Butt weld is to connect pipes and fittings ends by butt welding process. Also known by welded pipe fittings. It has ends in beveled or plain, dimensions normally from 3/4” to 24”. Unlike the socket weld fittings sizes below NPS 2”, butt weld fittings size can reach to a specific range, you will find that the butt weld fittings range in size from 1/2” to 72”. They are manufactured according to ASME B16.9; material in carbon, alloy and stainless steel. Butt-Weld Fittings are available in variety of kinds such as tees, caps, elbows, reducers and outlets. These fittings are the most common type of welded pipe fitting and are specified by nominal pipe size and pipe schedule. This fitting then becomes part of a system for transporting fluids (oil, gas, steam, chemicals, …) in a safe and efficient manner, over short or long distances. Other types of fittings can be threaded or socket welded.

There are many different types and shapes in the market.

- There are different parameters to be considered before purchasing and that is the size of the pipe fittings in diameter, thickness of the wall to be according to the pressure in the pipes, materials, shape and many others.

- Buttweld fittings use seamless or welded pipe as the starting material and are forged (through multiple process) to get the shape of elbows, tees and reducers etc. Just as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold the same way. Welded butt weld fittings are more common in stainless steel due to cost advantage. Sch 10 fittings are also more common in stainless steel butt weld fitting. A common example using welded pipe fitting is a pipe reduced by concentric reducer, welded to a weld neck flange and connected to an equipment.

- Other types of fittings can be threaded or socket welded.

Standards and Specifications for Butt Weld Pipe Fittings

| Standard | Grade and Specification |

| ASME | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.28 | Wrought Steel Short Radius Elbows and Buttwelding Returns |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Materials and Grades for Butt Weld Pipe Fittings

| Material | Grade |

| Carbon Steel | WPB, WPC, WPL6 |

| Chrome Moly | WP5, WP9, WP11, WP12, WP22 |

| Stainless Steel | 304/304L, 316/316L, 304H, 316H, 309, 310S, 317L, 321/321H, 347/347H, 904L, DUPLEX 2205 / SUPER DUPLEX 2507 |

| High Yield Carbon Steel | WPHY42, WPHY52, WPHY65 |

| Nickel Alloys | Alloy 20, 200, 201, 400, 600, 625, 800H/HT, 825, 254SMO, AL6XN, C276, C22, B3, HAST-X |

| Standard Materials | Carbon, Stainless, Chrome Moly, High Yield, Low Temperature, Aluminum |

| Types | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses, Laterals, Olets, Return Bends |

| Sizes | Standard 1/2″ to 48″ (special order larger O.D. fittings) |

| Wall Sizes | Schedule 20 thru XXH, and Special Wall Sizes |

| Specialty Items | 3D & 5D Bends, Galvanizing, 100% X-ray Testing |

Butt Weld Dimensions

- Butt Welded Pipe Fittings Dimensions refer to pipe size standards ANSI B36.10 and B36.19.

- Diameter range: 1″, 2″, 3″, 4″, 6″, 8″ and maximum 72″.

- Thickness range: Schedule 10, Schedule 40, Schedule 80, XS, XXS and SCH 160

- In the case of involving mounting dimensions of butt welded fittings, this will include the diameter in the NPS and the thickness in the schedule.

Types of Butt Weld Pipe Fittings

- Pipe Elbows – Steel elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends.

- Pipe Bending – Pipe bend can be made of variety materials, like carbon steel, alloy steel, stainless steel, low temperature steel or high-performance steel, etc.

- Pipe Tees – We can provide seamless tube tees and welding tube tees, which can also be divided into straight tees and reducing tees. Usually, the pipe tees have the same inlet and outlet sizes.

- Pipe Cross – A pipe fitting, having four openings in the same place, at right angles to each other. A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or three inlets and one outlet.

- End Caps – End Cap, Carbon Steel cap, Stainless Steel Caps, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches. Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- Pipe Reducer – Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations.

- Stub End – Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End.

- Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Advantages of Butt Weld Pipe Fittings

- Various turning options and easy to weld.

- Butt weld saves more cost than socket weld or threaded.

- Allow thin thickness as SCH 10 or SCH 10S.

- Compatible with different sizes from 1/4 inch to 24 inch and up to 72 inch.

- Continuous metal structure increases the strength of the piping system.

What are Advantages of Butt Welding over Flanges?

- Flanges connect pipes by bolting them together, whereas butt weld fittings connect pipes by welding them together.

- Depending on size, butt weld fittings require 10% to 75% less material than a flanged connection, which means lower material cost and lower weight.

- Welded construction permits greater freedom in designing a layout; this system uses less space, is more compact, and has greater strength.

- Butt weld fittings provide optimum flow characteristics, without pockets or sharp corners, creating less frictional resistance, no pressure loss, less turbulence.

- The welded connection would help to get more robust connection.

- Continuous structure of metal would add to the strength of the piping system.

- When butt weld fittings would be matched with the appropriate pipe schedules, they would help to offer a seamless flow inside the pipe.

- It provides the option of various turn radius by using Long Radius, Short Radius, or 3R elbows.

- Found to be cost effective compared to the socket weld or threaded counterparts.

- These fittings would be available in Schedule 10, thus allowing for a thinner wall option.

- These fittings have been found to be more common in the configuration of Schedule 10 and Schedule 40.

What is a Seamless Butt Weld Fitting?

- A seamless butt weld pipe fitting is made directly from a section of seamless pipe material, by applying heat and pressure to transform pipe directly into an elbow or other shape.

- A seamless fitting has no welded parts by itself, a characteristic demanded in some critical applications.

- By comparison, a regular butt weld fitting has one, two or more welds, depending on dimension, shape and manufacturing method.

- No weld means less risk of weld yield and porosities.

Applications of Butt Weld Pipe Fittings

Fittings are used wherever liquids, gases, chemicals and other fluids are created, processed, transported, or used. Range of industries is very wide, as shown below:

- Energy related – Oil and gas industries, including upstream (exploration and production), midstream (transportation by ships, pipeline, rail, trucks; storage and wholesale) and downstream (refining into fuels or chemicals; marketing and distribution). Power plants using fossil or nuclear fuels. Geothermal energy for harnessing heat from the earth.

- Food and beverage production – From basic ingredients to elaborate desserts. From milk, to juices and other beverages. Cold chain to keep produce fresh, drinks and frozen foods at a set temperature. Desalination plants to transform seawater into drinking water for arid areas and various tropical islands.

- Pharmaceuticals and biotech production – Medicines and vaccines that treat illnesses and help restore bodies and minds to their top conditions.

- Semiconductor manufacturing – Microchips that go into all electronics, including smartphones, tablets, computers, television sets, telecom networks.

- Pulp and paper production – Newsprint, glossy paper, cardboard boxes, books, writing paper.

- Production of construction materials and plastics – From roofing materials, to glassmaking for windows, to copper wiring for transporting electricity, and various plastics throughout houses and office buildings.

How are Buttweld Pipe Fittings Manufactured?

Key steps in manufacturing process are as follows:

- Planning: based on fitting specifics and client requirements; includes creating part identification in manufacturing system.

- Selection of raw material: metal; plate or pipe.

- Cutting

- Heating

- Forming

- Welding: for fittings that are not simple elbows, returns, bends, reducers or caps.

- Inspection and tests: according to standards and client requirements.

- Coating (if required).

- Preparation of documentation.

- Shipping.

Testing & Inspection of Stainless Steel 304/304L Buttweld Pipe Fittings

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Stainless Steel 304/304L Buttweld Pipe Fittings

Prices for stainless steel 304/304L buttwelded fittings are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of stainless steel 304/304L buttweld pipe fittings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our pricelist for various steel products on our blog.

Documents Provided at the time of Domestic Sales or Export of Stainless Steel 304/304L Buttweld Pipe Fittings

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Gurantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Basis for Stainless Steel 304/304L Buttweld Pipe Fittings

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Stainless Steel 304/304L Buttweld Pipe Fittings

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not availabe in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Stainless Steel 304/304L Buttweld Pipe Fittings

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

About 304/304L Stainless Steels

What is 304/304L Stainless Steel?

- Grade 304 stainless steel has a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. The remainder of its composition is made up of carbon, manganese, silicon and very small amounts of phosphorous and sulfur. It is defined as a Chromium-Nickel austenitic alloy. Grade 304 is the standard “18/8” stainless that you will probably see in your pans and cookery tools. Additionally, the metal is pliable under both hot and cold working, though it responds better to cold working; it will only work harden under cold working. Extended exposure to temperatures between 800–1500°F can lead to embrittlement and should be carefully monitored.

- Grade 304L is the low carbon version of 304, and although the two types share many of the same properties, it is the differences in carbon content that differentiates them. It does not require post-weld annealing to effectively maximize corrosion resistance and so is extensively used in heavy gauge components (over about 6mm). Grade 304H with its higher carbon content finds application at elevated temperatures. Additionally, it also possesses a higher work hardening rate. 304L exhibits excellent resistance in a variety of atmospheres and temperatures, along with the corrosion and oxidation that occurs over time. However, like many stainless steels, it is susceptible to warm chlorine environments and can potential pit and crack.

- Stainless Steels 304 and 304L can be commonly found dually certified. This utilized the widely applicable properties of both metals and meets the individual specifications for each.Grade 304/304L is the most widely used commercial grade of stainless steel supplied into numerous industry sectors. It has excellent corrosion resistance in ordinary atmospheric conditions, it is easily machined and is also easy to weld. Whilst performing well when exposed to relatively high temperatures, this grade of stainless steel like most austenitic stainless grades, also maintains its strength and toughness at sub-zero temperatures, making this an excellent choice for various applications and industries such as food & drink processing, petrochemical and construction.

Product Forms and Standards of 304/304L Stainless Steel

| Product Forms | Material Standards |

| Plates, Sheets & Strips | ASTM A240, A666 |

| Billets, Bars & Rods | ASTM A276, A314, A479 |

| Forgings(Flanges & Fittings) | ASTM A182, A473. |

| Wires | ASTM A313, A368, A478, A492, A493, A580. |

| Seamless and Welded Pipes | ASTM A312, A358, A813, A814. |

| Wrought Pipe Fittings | ASTM A403 |

| Castings(Cast Fittings & Valve Parts) | ASTM A351, A743, A744 |

Applications of Stainless Steel 304 Materials

SS 304 is a stainless steel with applications ranging from the manufacturing of chemical equipment, kitchen and cooking utensils and equipment, to surgical tools and textile dyeing equipment. SS 304L is used for applications where a low carbon count is required, such as in heavy gauge components. It is often applied in areas of higher temperatures than Type 304 can endure, and its low carbon allow it to be resistant against carbon precipitation. It is used for a wide variety of home and commercial applications, this is one of the most familiar and most frequently used alloys in the stainless steel family. Typical applications include tanks and containers for a large variety of liquids and solids:

- Food industry

- Domestic tools industry

- Architectural panelling, railings & trim

- Chemical containers, including for transport

- Heat Exchangers

- Woven or welded screens for mining, quarrying & water filtration

- Dyeing industry

- In the marine environment, because of it slightly higher strength and wear resistance than type 316 it is also used for nuts, bolts, screws, and other fasteners.

Chemical & Mechanical Properties of Stainless Steel 304/304L

| Material | UNS | EN | Chemical Component % | ||||||

| C | Mn | P | S | Si | Cr | Ni | |||

| 304 | S30400 | 1.4301 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 18.00-20.00 | 8.00-10.00 |

| 304L | S30403 | 1.4307 | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 18.00-20.00 | 8.00-10.00 |

| Material | UNS | EN | Tensile Strength | Yield Strength | Elongation | Heat Treatment |

| (Mpa) min | (Mpa) min | (%) | ℃ | |||

| 304 | S30400 | 1.4301 | 515 | 205 | 35 | 1040 |

| 304L | S30403 | 1.4307 | 485 | 170 | 35 | 1040 |

Properties and Processing Characteristics of Stainless Steel 304/304L

- The metal is characterized by its corrosion resistance, especially in cases of oxidation and salt water. Otherwise referred to as Grade 304 or Type 304, it is the most commonly utilized grade of stainless steel, being extremely versatile in application, form, and finishes. This makeup ensures that SS 304 has a well-balanced level of performance in terms of weldability, corrosion resistance and anti-oxidation properties.

- Alloy 304/304L has excellent strength and toughness at cryogenic temperatures. Alloy 304/304L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or welding. It can be easily welded and processed by standard shop fabrication practices.

- Good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C. Continuous use of 304 in the 425- 860°C range is not recommended if subsequent aqueous corrosion resistance is important. Grade 304L is resistant to carbide precipitation and can be heated into this

temperature range. - Heat treatment – Solution Treatment (Annealing) to 1010-1120°C and cool rapidly. These grades cannot be hardened by thermal treatment.

Equivalents of Stainless Steel 304/304L

| STANDARD | SS 304 | SS 304L | SS 304H |

| UNS | S30400 | S30403 | S30409 |

| WERKSTOFF NR. | 1.4301 | 1.4306 | 1.4948 |

Physical Properties of Stainless Steel 304/304L

- Density: 8.03g/cm3

- Electrical resistivity: 72 microhm-cm (20C)

- Specific Heat: 500 J/kg °K (0-100°C)

- Thermal conductivity: 16.3 W/m-k (100°C)

- Modulus of Elasticity (MPa): 193 x 103 in tension

- Melting Range: 2550-2650°F (1399-1454°C)

Corrosion Resistance of 304/304L Stainless Steel

- Alloy 304/304L has good resistance to atmospheric corrosion, foods and beverages and to many organic and inorganic chemicals in moderately oxidizing to moderately reducing environments. The high chromium content of the alloy provides resistance to oxidizing solutions such as nitric acid up to 55% weight and up to 176°F (80°C). Alloy 304/304L also resists moderately aggressive organic acids such as acetic. The nickel present in the alloy provides resistance to moderately reducing solutions such as pure phosphoric acid, whatever the concentration, in cold solutions and up to 10% diluted hot solutions. The alloy can also operate successfully in caustic solutions free of chlorides or fluorides at moderate temperatures.

- Alloy 304/304L does not perform well in more highly reducing environments such as those containing chlorides and sulfuric acid. Alloy 304/304L performs well in fresh water service with low levels of chlorides (less than 100ppm). At higher chloride levels the grade is susceptible to crevice corrosion and pitting. For successful performance under these more severe conditions, higher molybdenum content is need such as 316/316L. Alloy 304/304L is not recommended for service in marine environments.

- In most instances, the corrosion resistance of Alloys 304, 304L and 304H will be roughly equal in most corrosive environments. However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones Alloy 304L should be used because of its low carbon content.

Fabrication Data of Stainless Steel 304/304L

Alloy 304/304L can be easily welded and processed by standard shop fabrication practices.

- Hot Forming:- Working temperatures of 1652–2102°F (750–1150°C) are recommended for most hot working processes. For maximum corrosion resistance, the material should be annealed at 1900°F (1038°C) minimum and water quenched or rapidly cooled by other means after hot working.

- Cold Forming:- The alloy is quite ductile and forms easily. Cold working operations will increase the strength and hardness of the alloy and might leave it slightly magnetic.

- Welding:- Alloy 304/304L can be readily welded by most standard processes. A post weld heat treatment is not necessary.

- Machining:- Alloy 304/304L is subject to work hardening during deformation and is subject to chip breaking. The best machining results are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling and powerful rigid equipment.