Lap Joint Stub End Manufacturers, Suppliers, Stockist – ASME B16.9 Stub Ends, MSS SP 43 Stub End

- Metallica is one of the biggest suppliers and manufacturer of lap joint stub ends in India, with sales across the globe. A lap joint stub end and its associated slip on flange in a piping system allows quick disconnection of the particular section involved. Stub ends are installed in pairs and mated together with two lap joint flanges. The surface of the stub end has a phonographic serrated gasket surface which prevents leakage at the joint.

- Stub ends are typically manufactured by two methods – Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions. Stub Ends are available in two standard lengths – MSS and ANSI. Lap Joint Stub Ends are normally provided with a standard weld bevel. Lap Joint Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

- A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone; the flange only provides the clamping pressure on the joint.

- Since Lap Joint Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

Production & Supply Range for Lap Joint Stub Ends

| Product | Lap Joint Stub End |

| Size | 1/2″ to 24″ |

| Thickness | Sch 10s, 20, STD, 40, 80, 160, XXS |

| Type | Type A, Type B, Type C, Collar Type |

| Length | Long Pattern and Short Pattern |

| Design Standard | ASME B16.9, MSS SP 43 |

Material Grades for Producing Lap Joint Stub Ends

| Stainless Steel | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel | ASTM A 182 – F 51, F53, F55, UNS S31803, UNS S32205, UNS S32750, UNS S32760 |

| Carbon Steel | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C |

| Alloy Steel | ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel | ASTM/ASME SB 111 UNS NO. C10100, C10200, C10300, C10800, C12000, C12200, C70600, C71500, ASTM / ASME SB 466 UNS NO. C70600 ( CU -NI- 90/10), C71500 ( CU-NI- 70/30) |

| Nickel Alloy Steel | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

What are the Various Types of Stub Ends?

Stub end belongs to buttweld fittings, and there are mainly two standard for stub end fabrication. One is ASME B16.9, which is the most common used standard for buttweld pipe fittings. The other is MSS-SP-43, a specification standard for Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications.

Lap Joint stub end has different types, and based on the length they are also available in long pattern and short pattern. Type A stub end and Type B stub end are more prevalent.

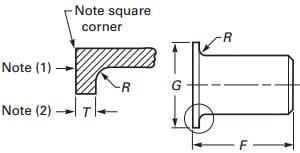

Type A Stub End

- Used with standard lap joint flange.

- Lap thickness is larger than or equal to pipe wall thickness.

- Outside corner radius is accommodated to the lap joint flange, inside corner is squared.

- Machined serrated face.

Type B Stub End

- Suit for slip on flanges acting as lap joint flanges.

- Lap thickness is greater than or equal to the wall thickness of connection pipes.

- Outside corner radius is small in order to receive slip on flange acting as a backup flange, inner corner is square.

- Machined serrated face.

Type C Stub End

- Used with lap joint flanges and slip on flanges.

- Lap thickness is 75% of connection pipes.

- It is flared and the radius can be closed to square if it’s necessary.

- Smooth surface.

Stub Ends are available in two lengths, MSS and ANSI.

- MSS – MSS is the standard length Stub End.

- ANSI – ASA is the long length Stub End.

Dimensions of ASME B16.9 Lap Joint Stub Ends

| Nominal Size | Outside Diameter of Barrel | Long Pattern | Short Pattern | Radius of | Diameter | |

| Length, F | Length, F | Fillet, R | of Lap, G | |||

| NPS | Max. | Min. | mm. | mm. | mm. | mm. |

| mm. | mm. | in. | in. | in. | in. | |

| in. | in. | |||||

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 0.896 | 0.809 | 3 | 2 | 0.12 | 1.38 | |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1.106 | 1.019 | 3 | 2 | 0.12 | 1.69 | |

| 1 | 35 | 32.6 | 102 | 51 | 3 | 51 |

| 1.376 | 1.284 | 4 | 2 | 0.12 | 2 | |

| 1 1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1.716 | 1.629 | 4 | 2 | 0.19 | 2.5 | |

| 1 1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 1.965 | 1.869 | 4 | 2 | 0.25 | 2.88 | |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2.456 | 2.344 | 6 | 2.5 | 0.31 | 3.62 | |

| 2 1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 2.966 | 2.844 | 6 | 2.5 | 0.31 | 4.12 | |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3.596 | 3.469 | 6 | 2.5 | 0.38 | 5 | |

| 3 1/2 | 104 | 100.8 | 152 | 76 | 10 | 140 |

| 4.096 | 3.969 | 6 | 3 | 0.38 | 5.5 | |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 4.593 | 4.469 | 6 | 3 | 0.44 | 6.19 | |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 5.683 | 5.532 | 8 | 3 | 0.44 | 7.31 | |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 6.743 | 6.594 | 8 | 3.5 | 0.5 | 8.5 | |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 8.743 | 8.594 | 8 | 4 | 0.5 | 10.62 | |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 10.913 | 10.719 | 10 | 5 | 0.5 | 12.75 | |

| 12 | 328 | 323.1 | 254 | 152 | 13 | 381 |

| 12.913 | 12.719 | 10 | 6 | 0.5 | 15 | |

| 14 | 359.9 | 354.8 | 305 | 152 | 13 | 413 |

| 14.17 | 13.969 | 12 | 6 | 0.5 | 16.25 | |

| 16 | 411 | 405.6 | 305 | 152 | 13 | 470 |

| 16.18 | 15.969 | 12 | 6 | 0.5 | 18.5 | |

| 18 | 462 | 456 | 305 | 152 | 13 | 533 |

| 18.19 | 17.969 | 12 | 6 | 0.5 | 21 | |

| 20 | 514 | 507 | 305 | 152 | 13 | 584 |

| 20.24 | 19.969 | 12 | 6 | 0.5 | 23 | |

| 22 | 565 | 558 | 305 | 152 | 13 | 641 |

| 22.24 | 21.969 | 12 | 6 | 0.5 | 25.25 | |

| 24 | 616 | 609 | 305 | 152 | 13 | 692 |

| 24.24 | 23.969 | 12 | 6 | 0.5 | 27.25 | |

- All dimensions are furnished in both SI(metric) units and US Customary units.

- Gasket face finish shall be in accordance with ASME B16.5 for raised face flanges.

- The lap thickness, T, shall not be less than nominal pipe wall thickness.

- When short pattern stub ends are used with larger flanges in Classes 300 and 600, with most sizes in Classes 900 and higher, and when long pattern stub ends are used with larger flanges in Classes 1500 and 2500, it may be necessary to increase the length of the stub ends in order to avoid covering the weld with the flange.

- When special facings such as tongue and groove, male and female, etc., are employed, additional lap thickness must be provided and such additional thickness shall be in addition to (not included in) the basic length, F.

- Dimensions of “Radius of Fillet, R” conform to the radius established for lap joint flanges in ASME B16.5.

- Dimensions of “Diameter of Lap, G” conform to standard machined facings shown in ASME B16.5.

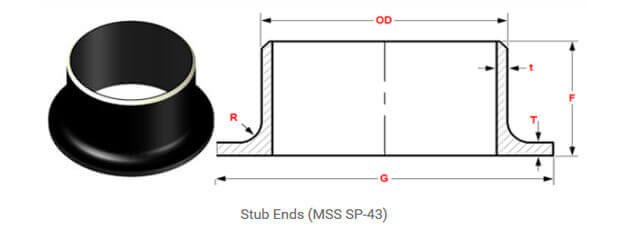

MSS SP-43 Dimensions of Lap Joint Stub Ends

- SCH 10S Stub Ends

| NPS | OD | T | G | F | R | kg |

| 1/2 | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 |

| 3/4 | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.1 |

| 1 | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 |

| 1¼ | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 |

| 1½ | 48.3 | 2.77 | 73 | 50.8 | 6.35 | 0.25 |

| 2 | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 |

| 2½ | 73 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 |

| 3 | 88.9 | 3.05 | 127 | 63.5 | 9.53 | 0.73 |

| 4 | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 |

| 5 | 141.3 | 3.4 | 185.7 | 76.2 | 11.11 | 1.47 |

| 6 | 168.3 | 3.4 | 215.9 | 88.9 | 12.7 | 2.15 |

| 8 | 219.1 | 3.76 | 269.9 | 101.6 | 12.7 | 3.22 |

| 10 | 273.1 | 4.19 | 323.9 | 127 | 12.7 | 5.13 |

| 12 | 323.9 | 4.57 | 381 | 152.4 | 12.7 | 8.16 |

| 14 | 355.6 | 4.78 | 412.8 | 152.4 | 12.7 | 10.89 |

| 16 | 406.4 | 4.78 | 469.9 | 152.4 | 12.7 | 12.7 |

| 18 | 457.2 | 4.78 | 533.4 | 152.4 | 12.7 | 17.24 |

| 20 | 508 | 5.54 | 584.2 | 152.4 | 12.7 | 21.77 |

| 24 | 609.6 | 6.35 | 692.2 | 152.4 | 12.7 | 27.22 |

ASME/ANSI and MSS SP-43 Dimensions

| inches | ND | mm | Diameter of lap | Radius of fillet | Length F | ||

| D | G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21.34 | 34.92 | 3.17 | 0.8 | 50.8 | 76.2 |

| 3/4 | 20 | 26.67 | 42.86 | 3.17 | 0.8 | 50.8 | 76.2 |

| 1 | 25 | 33.4 | 50.8 | 3.17 | 0.8 | 50.8 | 101.6 |

| 1 1/4 | 32 | 42.16 | 63.5 | 4.76 | 0.8 | 50.8 | 101.6 |

| 1 1/2 | 40 | 48.26 | 73 | 6.35 | 0.8 | 50.8 | 101.6 |

| 2 | 50 | 60.32 | 92.1 | 7.93 | 0.8 | 63.5 | 152.4 |

| 2 1/2 | 65 | 73.02 | 104.8 | 7.93 | 0.8 | 63.5 | 152.4 |

| 3 | 80 | 88.9 | 127 | 9.52 | 0.8 | 63.5 | 152.4 |

| 3 1/2 | 90 | 101.6 | 139.7 | 9.52 | 0.8 | 76.2 | 152.4 |

| 4 | 100 | 114.3 | 157.2 | 11.11 | 0.8 | 76.2 | 152.4 |

| 5 | 125 | 141.3 | 185.7 | 11.11 | 1.58 | 76.2 | 203.2 |

| 6 | 150 | 168.27 | 215.9 | 12.7 | 1.58 | 88.9 | 203.2 |

| 8 | 200 | 219.07 | 269.8 | 12.7 | 1.58 | 101.6 | 203.2 |

| 10 | 250 | 273.05 | 323.8 | 12.7 | 1.58 | 127 | 254 |

| 12 | 300 | 323.85 | 381 | 12.7 | 1.58 | 152.4 | 254 |

| 14 | 350 | 355.6 | 412.7 | 12.7 | 1.58 | 152.4 | 304.8 |

| 16 | 400 | 406.4 | 469.9 | 12.7 | 1.58 | 152.4 | 304.8 |

| 18 | 450 | 457.2 | 533.4 | 12.7 | 1.58 | 152.4 | 304.8 |

| 20 | 500 | 508 | 584.2 | 12.7 | 1.58 | 152.4 | 304.8 |

| 22 | 550 | 558.8 | 641.3 | 12.7 | 1.58 | 152.4 | 304.8 |

| 24 | 600 | 609.6 | 692.1 | 12.7 | 1.58 | 152.4 | 304.8 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||