Alloy Steel Forgings, Seamless Rolled Rings & Forged Block Manufacturers – A788, 4130, 4140, 4150, F1, F5, F9, F11, F12, F22, F91, Alloys 4330, 4340, 8620, 8630, and 9310

| Alloy Steel Forged Automotive Components | Alloy Steel Forged Wheel Components |

| Alloy Steel Forged Truck Components | Alloy Steel Forged Transmission Components |

| Alloy Steel Forged Tractor Components | Alloy Steel Forged Suspension Components |

| Alloy Steel Forged Gear Components | Alloy Steel Forged Brake Components |

| Alloy Steel Forged Metal Building Components | Alloy Steel Forged Axle Components |

| Alloy Steel Forged Shaft Components | Alloy Steel Forged Chassis Components |

| Alloy Steel Forged Trailer Components | Alloy Steel Forged Container Components |

| Alloy Steel Forged Steering Components | Alloy Steel Forged Machine Components |

| Alloy Steel Forged Railway Components | Alloy Steel Forged Engine Components |

| Alloy Steel Forged Vehicle Components | Alloy Steel Forged Metal Components |

| Alloy Steel Forged Aerospace Components |

In addition to above alloy steel forged components, we may manufacture the forged components according to the clients’ drawings or requirements. If you need a good alloy steel forging manufacturer, please send your inquiry to us.

- We are manufacturing a wide range of optimum quality alloy steel forgings & shafts which include alloy steel rolled ring, alloy steel die blocks, alloy steel square blocks, alloy steel rectangular and alloy steel circular blocks and alloy steel machined components. The maximum length for forged round bars and hex bars is 5000 mm, with a maximum weight of 18000 kgs. The maximum length and width for flat bars and square bars is 1500mm, with a maximum weight of 25000 kgs.

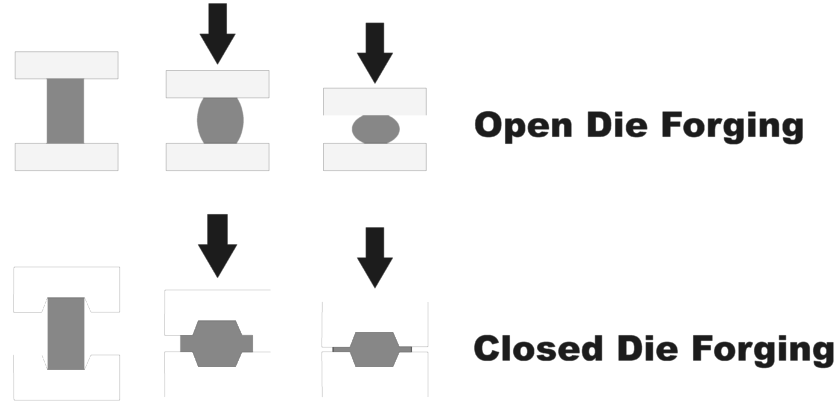

- Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state using high pressure, either by striking it with a hammer or by pressing it with a die. Modern forged steel is conducted using specialized machines or hydraulic hammers. The material is often heated beforehand in order to make forging easier, but it remains solid throughout the process.

- Kitchen knives and other knife blades are typical examples of products made via forging. Since steel can either be forged or cast, manufacturers usually specify the actual material grade and type as “cast steel” or “forged steel” to clarify which process was utilized. Austenitic Stainless Steel is considered to be “friendly” in forging terms.

- Forged steel is an alloy of carbon and iron that is compressed under extreme pressure to make a very hard and strong substance. It has been used for thousands of years to create all types of materials.

- ASTM A29 Grade 4130 steel should be forged between 1230 and 950 º C (2250 and 1750 º F). The lower the finishing temperature from forging, the finer will be the grain size. If the 4130 alloy steel is forged at too low a temperature, there is a risk of the formation of a non-uniform structure in certain areas of the forged part, necessitating a normalizing treatment, prior to further heat treatment.

- Manufacturing Process of Forgings: A forged bar or a rolled bar is produced by taking an ingot and forging it down to size by, generally, two opposing flat dies. Forging offers uniformity of composition and structure. Forging results in metallurgical recrystallisation and grain refinement as a result of the thermal cycle and deformation process. This strengthens the resulting steel product particularly in terms of impact and shear strength. Forged steel is generally stronger and more reliable than castings and plate steel due to the fact that the grain flows of the steel are altered, conforming to the shape of the part. We are an industry leading alloy steel forging manufacturer and guarantee that the forgings and/or bars are homogenous in quality and free of any kind of defects, which can be tested by destructive or non destructive process.

- At Metallica, alloy steel forgings are manufactured by following a stringent quality control program and standards which assure good surface and close dimensional tolerances. We are a global industry leading provider of high quality alloy steel forgings and have obtained ASME Quality and ISO 9001:2015 Certifications. All alloy steel forged stock products supplied by us have good corrosion resistance, machinability and formability. These are supplied with 3.1 specific test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of ordering. Metallica makes it easy for you to source top quality steel forgings at the lowest prices in the industry.

- We specialize in providing deliveries to your factory directly from our warehouse/factory or our principal suppliers. For immediate deliveries of alloy steel forgings, our inventory in stocked in around 5 warehouses in Kalamboli and 3 warehouses in Mumbai. With a team of over 50 people dedicated for deliveries and response to our esteemed customers, we can offer the best service. At the same time, we are also committed to offer best quality products and most competitive prices to our customers.

Wide Range of Alloy Steel Forging Products

Alloy Steel Forgings, Rings, Blocks Manufacturing Process

- Alloy Steel Forged Discs & Blanks – We are producing alloy steel forged discs in size range of 2″ to 100″ diameter, and individual weights up to 25000 KGS. Alloy Steel Forged discs are manufactured by working or pressing of heated material between the upper and lower dies. They are generally produced by the open die forging process and exhibit better grain structure, superior strength, ductility, and resistance to impact and fatigue as compared to discs cut from plate or bar stock. Alloy Steel Forged discs can be forged with grain flow to best suit the final parts applications.

- Alloy Steel Forged Bars – A forged bar or a rolled bar is produced by taking a heated ingot and sizing it between two opposing flat dies. We specialize in producing all types of forged bar shapes such as Round bars, Square bars, Flat bars and Hex bars in stainless steel, alloy steel, carbon steel and special alloys. The producing process for all types of alloy steel forgings involves loading the materials in furnace followed by heating. When the temperature reaches 1100℃, metal will be forged. In the forging process the heated metal is shaped by using one or more dies. During the forging or rolling process if the temperature of metal falls to 850℃, metal will be heated again. Then the hot working process is repeated at that elevated temperature (1100℃). We can offer all types of alloy steel forged bars in annealed, tempered or quenched and tempered condition, as per customer requirements.

- Alloy Steel Forged Blocks – Alloy Steel Forged blocks are of higher quality than plate due to the block having forging reduction on all sides of the shape, if required. This leads to a refined grain structure, assuring that quality of material. The maximum alloy steel forged block dimensions depend on material grade. We can produce larger size blocks in alloy steel. In alloy steel, large size forged blocks can be in size upto 750mm x 750mm in variable lengths. In carbon and alloy steel we can produce forged blocks upto 1500mm size.

- Alloy Steel Forged Rings – Seamless alloy steel forged rings can be formed by rolling or piercing a forged block. Large size seamless rolled or forged rings can be produced in outside diameter upto 2500mm.

- Alloy Steel Seamless Forged Hollows – Alloy steel forged hollow bars can be produced in unlimited variations of OD and ID and length as per customer requirements. Seamless alloy steel forged hollows are ideal for high-stress applications. All the processes including heat treatment, machining and mechanical and non-destructive testing are carried out and can be agreed upon at the time of order.

ASTM Standards for Forgings

| ASTM Designation | Title |

| A266/A266M | Carbon Steel Forgings for Pressure Vessel Components |

| A288 | Carbon and Alloy Steel Forgings for Magnetic Retaining Rings for Turbine Generators |

| A289/A289M | Alloy Steel Forgings for Nonmagnetic Retaining Rings for Generators |

| A290/A290M | Carbon and Alloy Steel Forgings for Rings for Reduction Gears |

| A291/A291M | Steel Forgings, Carbon and Alloy, for Pinions, Gears, and Shafts for Reduction Gears |

| A336/A336M | Alloy Steel Forgings for Pressure and High-Temperature Parts |

| A372/A372M | Carbon and Alloy Steel Forgings for Thin-Walled Pressure Vessels |

| A469/A469M | Vacuum-Treated Steel Forgings for Generator Rotors |

| A470/A470M | Vacuum-Treated Carbon and Alloy Steel Forgings for Turbine Rotors and Shafts |

| A471/A471M | Vacuum-Treated Alloy Steel Forgings for Turbine Rotor Disks and Wheels |

| A473 | Stainless Steel Forgings |

| A504/A504M | Wrought Carbon Steel Wheels |

| A508/A508M | Quenched and Tempered Vacuum-Treated Carbon and Alloy Steel Forgings for Pressure Vessels |

| A541/A541M | Quenched and Tempered Carbon and Alloy Steel Forgings for Pressure Vessel Components |

| A579/A579M | Super strength Alloy Steel Forgings |

| A592/A592M | High-Strength Quenched and Tempered Low-Alloy Steel Forged Parts for Pressure Vessels |

| A646/A646M | Premium Quality Alloy Steel Blooms and Billets for Aircraft and Aerospace Forgings |

| A649/A649M | Forged Steel Rolls Used for Corrugating Paper Machinery |

| A668/A668M | Steel Forgings, Carbon and Alloy, for General Industrial Use |

| A711/A711M | Steel Forging Stock |

| A723/A723M | Alloy Steel Forgings for High-Strength Pressure Component Application |

| A729/A729M | Carbon and Alloy Steel Axles, Heat Treated, for Mass Transit and Electric Railway Service |

| A765/A765M | Carbon Steel and Low-Alloy Steel Pressure-Vessel-Component Forgings with Mandatory Toughness Requirements |

| A837/A837M | Steel Forgings, Alloy, for Carburizing Applications |

| A859/A859M | Age-Hardening Alloy Steel Forgings for Pressure Vessel Components |

| A891/A891M | Precipitation Hardening Iron Base Superalloy Forgings for Turbine Rotor Disks and Wheels |

| A909/A909M | Steel Forgings, Microalloy, for General Industrial Use |

| A965/A965M | Steel Forgings, Austenitic, for Pressure and High Temperature Parts |

| A982/A982M | Steel Forgings, Stainless, for Compressor and Turbine Airfoils |

| A983/A983M | Continuous Grain Flow Forged Carbon and Alloy Steel Crankshafts for Medium Speed Diesel Engines |

| A986/A986M | Magnetic Particle Examination of Continuous Grain Flow Crankshaft Forgings |

| A1021/A1021M | Martensitic Stainless Steel Forgings and Forging Stock for High-Temperature Service |

| A1049/A1049M | Stainless Steel Forgings, Ferritic/Austenitic (Duplex), for Pressure Vessels and Related Components |

| A1090/A1090M | Forged Rings and Hollows for Use as Base Plates in Power Transmission Structures |

Grades of Alloy Steel Forgings

| 4130, 4140, 4150 | Alloy steels 4130, 4140, and 4150 are all chromium-molybdenum steels. The elements molybdenum and chromium are used to strengthen these materials. Forgings made from these metals are tough with high fatigue strengths. |

| 4330, 4340, 8620, 8630, 9310. | Alloys 4330, 4340, 8620, 8630, and 9310 contain chromium and molybdenum as well as nickel. The addition of nickel makes these materials useful for applications involving exposure to heat. Products forged from any of these materials can undergo hardening by heat treatment as well as case hardening and are known for good strength, toughness, and wear characteristics in addition to fatigue strength. |

| 52100 | Alloy 52100 is a low alloy steel which contains high levels of chromium and carbon. These alloying elements allow 51200 forgings to be through hardened as well as resistant to corrosion. |

| NITRALLOY 135™ | A low alloy steel, Nitralloy 135™ is known as a nitriding grade and is a good material for case hardening. Products forged from this material exhibit high levels of resiliency and hardness. |

Types of Forging Materials

Stainless Steel Forgings, Rings & Blocks

- Stainless Steel 304/304L Forgings, Rings & Blocks

- Stainless Steel 304H Forgings, Rings & Blocks

- Stainless Steel 310/310S Forgings, Rings & Blocks

- Stainless Steel 316/316L Forgings, Rings & Blocks

- Stainless Steel 316Ti Forgings, Rings & Blocks

- Stainless Steel 317/317L Forgings, Rings & Blocks

- Stainless Steel 321/321H Forgings, Rings & Blocks

- Stainless Steel 347 Forgings, Rings & Blocks

- Stainless Steel 347H Forgings, Rings & Blocks

- Stainless Steel 410 Forgings, Rings & Blocks

- Stainless Steel 446 Forgings, Rings & Blocks

- Stainless Steel 904L Forgings, Rings & Blocks

Alloy Steel/Chrome Moly Forgings, Rings & Blocks

- Alloy Steel F1 Forgings, Rings & Blocks

- Alloy Steel F5 Forgings, Rings & Blocks

- Alloy Steel F9 Forgings, Rings & Blocks

- Alloy Steel F11 Forgings, Rings & Blocks

- Alloy Steel F12 Forgings, Rings & Blocks

- Alloy Steel F22 Forgings, Rings & Blocks

- Alloy Steel F91 Forgings, Rings & Blocks

- EN 19 Steel Forgings, Rings & Blocks

- 4140 Steel Forgings, Rings & Blocks

- 4130 Steel Forgings, Rings & Blocks

- 4340 Steel Forgings, Rings & Blocks

- 42CrMo4 Steel Forgings, Rings & Blocks

Hastelloy Forgings, Rings & Blocks

- Hastelloy C22 Forgings, Rings & Blocks

- Hastelloy C276 Forgings, Rings & Blocks

- Hastelloy B2 Forgings, Rings & Blocks

- Hastelloy B3 Forgings, Rings & Blocks

- Hastelloy X Forgings, Rings & Blocks

Nickel Forgings, Rings & Blocks

- Nickel 200 Forgings, Rings & Blocks

- Nickel 201 Forgings, Rings & Blocks

Special Alloy Forgings, Rings & Blocks

- Alloy 20 Forgings, Rings & Blocks

- SMO 254 Forgings, Rings & Blocks

- Aluminium Forgings, Rings & Blocks

- AISI 8620 Steel Forgings, Rings & Blocks

Mild Steel Forgings, Rings & Blocks

- AISI 1045 Steel Forgings, Rings & Blocks

- ASTM A36 Forgings, Rings & Blocks

- S355J2 Forgings, Rings & Blocks

Duplex Steel Forgings, Rings & Blocks

- Duplex Steel S31803 / S32205 Forgings, Rings & Blocks

- Super Duplex Steel S32750/ S32760 Forgings, Rings & Blocks

Titanium Forgings, Rings & Blocks

- Titanium Gr 2 Forgings, Rings & Blocks

- Titanium Gr 5 Forgings, Rings & Blocks

Inconel Hex Forgings, Rings & Blocks

- Inconel 600 Forgings, Rings & Blocks

- Inconel 601 Forgings, Rings & Blocks

- Inconel 625 Forgings, Rings & Blocks

- Inconel 718 Forgings, Rings & Blocks

Incoloy Forgings, Rings & Blocks

- Incoloy 800 / 800H / 800HT Forgings, Rings & Blocks

- Incoloy 825 Forgings, Rings & Blocks

- Incoloy 925 Forgings, Rings & Blocks

- Incoloy 330/ SS 330/ Ra 330 Forgings, Rings & Blocks

Monel Forgings, Rings & Blocks

- Monel 400 Forgings, Rings & Blocks

- Monel K500 Forgings, Rings & Blocks

Cupro Nickel Forgings, Rings & Blocks

- Cupro Nickel 90/10 Forgings, Rings & Blocks

- Cupro Nickel 70/30 Forgings, Rings & Blocks

- Copper Forgings, Rings & Blocks

- Brass Forgings, Rings & Blocks

Carbon Steel Forgings, Rings & Blocks

- Carbon Steel A105 Forgings, Rings & Blocks

- Carbon Steel A350 LF2 Forgings, Rings & Blocks

- Carbon Steel AISI 1018 Forgings, Rings & Blocks

- C45 Steel Forgings, Rings & Blocks

- EN8 Steel Forgings, Rings & Blocks

- EN8D Steel Forgings, Rings & Blocks

Chrome Steel Forgings, Rings & Blocks

- 16MNCR5 Steel Forgings, Rings & Blocks

- 20MNCR5 Steel Forgings, Rings & Blocks

- 40CR4B Steel Forgings, Rings & Blocks

- 41CR4 Steel Forgings, Rings & Blocks

- 52100 Steel Forgings, Rings & Blocks

Alloy Steel Forgings, Rings & Blocks Specifications, Stock & Production Range

| Commodity | Special Forging, Flange, Disc, Forging Fitting, Block, Tubesheet |

| Process method | Forged, CNC Machined |

| Materials Grades | F316L, F316, F304L, AISI 410, AISI 410S, F321, F44, F51, F54, F55, F904L, etc. |

| Standards: | ASTM A182 ,A266, A105 or closer |

| Forged Size | Ring: OD up to 2000 mm, High to 500 mm or as per drawing. Flange: NPS 1/2″ to 48″ or as per drawing. Fitting: NPS 1/2″ to 48″ or as per drawing Disc & Block: as per the request. |

| Condition | Anneal, Normalize, Normalize + Temper, Quench + Temper, as requirements |

| Inspection Testing | Mechanical Test, Hardness Test, Inter-granular corrosion Test, Ultrasonic Test, PT, MT, Hydraulic Test, or as required |

| Certificate | EN 1024 3.1/ 3.1B/ 3.2, PED, DNV, TUV. |

| Packing | Wooden case/ Steel framed plywood case/ simple packing. |

| Delivery Time | By mutual agreement. |

| We also can provide High quality Special Alloys forgings as well as non-standards forgings. | |

- Email Us on info@metallicametals.com for best prices on various types of Alloy Steel Forgings

- Marking: Heat Number, Size, Grade, Manufacturing Spec., Commodity Name or as per customer request

Processes of Alloy Steel Forging

- Impression Die Forging or Closed Die Forging

- Cold Forging

- Open Die Forging

- Seamless Rolled Ring Forging

- Upset Forging or Upsetting

- Piercing

- Precision Forging

- Trimming, Punching, Coining and Ironing

- Extrusion

Chemical Composition of Alloy Steel Forging

| Standard | Grade | C | Mn | P | S | Si | Cr | Mo |

| ASTM A29 | 4130 | 0.28-0.33 | 0.40-0.60 | 0.035 | 0.040 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| EN10250 /EN10083 | 25CrMo4/ 1.7218 | 0.22-0.29 | 0.60-0.90 | 0.025 | 0.035 | ≦0.40 | 0.90-1.2 | 0.15-0.30 |

| JIS G4105 | SCM430/ SCM2 | 0.28-0.33 | 0.60-0.85 | 0.030 | 0.030 | 0.15-0.35 | 0.90-1.2 | 0.15-0.30 |

Forging Temperature of Steel

| Steel Type | Maximum forging temperature (°F / °C) | Burning temperature (°F / °C) |

| 1.5% carbon | 1920 / 1049 | 2080 / 1140 |

| 1.1% carbon | 1980 / 1082 | 2140 / 1171 |

| 0.9% carbon | 2050 / 1121 | 2230 / 1221 |

| 0.5% carbon | 2280 / 1249 | 2460 / 1349 |

| 0.2% carbon | 2410 / 1321 | 2680 / 1471 |

| 3.0% nickel steel | 2280 / 1249 | 2500 / 1371 |

| 3.0% nickel–chromium steel | 2280 / 1249 | 2500 / 1371 |

| 5.0% nickel (case-hardening) steel | 2320 / 1271 | 2640 / 1449 |

| Chromium–vanadium steel | 2280 / 1249 | 2460 / 1349 |

| High-speed steel | 2370 / 1299 | 2520 / 1385 |

| Stainless steel | 2340 / 1282 | 2520 / 1385 |

| Austenitic chromium–nickel steel | 2370 / 1299 | 2590 / 1420 |

| Silico-manganese spring steel | 2280 / 1249 | 2460 / 1350 |

[Source: From Web]

Advantages of Forgings

- Generally tougher than alternatives

- Will handle impact better than castings

- The nature of forging excludes the occurrence of porosity, shrinkage, cavities and cold pour issues.

- The tight grain structure of forgings making it mechanically strong. There is less need for expensive alloys to attain high strength components.

- The tight grain structure offers great wear resistance without the need to make products “superhard” We have found that, on a blank HRC 38-42 forged grinder insert wear/wash is about the same as a high alloy HRC 46-50 cast grinder insert. The difference being a HRC 46-50 casting does not have the ductility to handle high impact grinding.

How to Identify whether Forging or Casting to be done

- Steel products may be manufactured either by casting or forging steel. Steel casting is the process by which a metal is heated until it reaches a liquid state and then poured into a mold that shapes the desired product. In Steel forging method, steel is physically forced into shape while remaining in a solid state – although it is frequently heated.

- Forged parts had a 26% higher tensile strength than the cast parts. This means you can have stronger shackles at a lower part weight. The reason behind is when you melt metal to cast it, the grain size is free to expand. When it cools back to a solid, the grain structure is courser and more random, decreasing its strength.

- Forged parts have a 37% higher fatigue strength resulting in a factor of six longer fatigue lives. This means that a forged shackle is going to last longer.

- Cast steel only has 66% of the yield strength of forged steel. Yield strength is an indicator of what load a shackle will hold before starting to deform.

- The forged parts had a 58% reduction in area when pulled to failure. The cast parts only had a 6% reduction in area. That means there would be much greater deformation before failure in a forged part.

Strength and Weakness of Forging and Casting

| Forging | Casting | |

| Strength | Good Mechanical properties (yield strength, ductility, toughness) | Large and complex parts |

| Reliability (used for critical parts) No liquid metal treatment | High production rate | |

| Design flexibility | ||

| Weakness | Laps | Shrinkage porosity |

| Die unfill | Metallic projections | |

| Die failure | Cracks, Hot tearing, Cold shuts | |

| Piping | Laps, Oxides | |

| Shape limited when undercuts or cored sections are required. | Misruns, Insufficient volume | |

| Overall cost usually higher than casting. | Inclusions | |

| Multiple steps often required. | Requires close process control and inspections (porosity may occur). |

Testing & Inspection of Alloy Steel Forgings, Rings & Blocks

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Alloy Steel Forgings, Rings & Blocks

Prices for alloy steel forgings, seamless rolled rings and forged blocks are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel forgings is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of alloy steel forgings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided – Domestic Sales or Export of Alloy Steel Forgings, Rings & Blocks

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Terms for Alloy Steel Forgings, Rings & Blocks

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Alloy Steel Forgings, Rings & Blocks

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Alloy Steel Forgings, Rings & Blocks

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

Suppliers of Alloy Steel Forgings, Rings & Blocks in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Exporters of Alloy Steel Forgings, Rings & Blocks

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu