Pipe Bend & Pigabble Bend Manufacturers – Long Bend with Radius-R = 3D, 5D & 10D | 3D Elbow, 5D Elbow, 6D Elbow, 8D Elbow, 10D Elbow Manufacturers, Suppliers

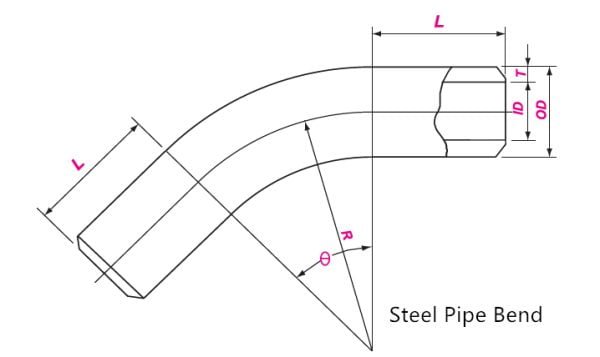

- Steel pipe bends are similar with elbows to some extent, they have same angle degree, thickness and size. The only difference is the pipe bending radius. Pipe elbow has LR (1.5D) & SR (1D) only. While bends R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) D means outside diameter. Its advantage is that it can match long distance transition requirements, so bend dimensions are commonly designed according to customer requirements. Manufacturing a pipe bend consist of various processes such as bending, squeezing, pressing, forging, machining and more. Metallica specializes in manufacturing long radius bends with Bending radius(R): R=3D, 5D, 6D, 7D, 8D, 10D and 12D, with Bending angle (θ):15°, 30°, 45°, 60°, 90°, 135°, 180°.

What is Difference between Pipe Elbow and Bend?

- Pipe bends typically have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than or equal to 1.5R, it is called Elbow. For example, 1.5D elbow we call it as long radius ( LR) elbow and 1D elbow as short radius ( SR) elbow. Accordingly, if the bend radius is 3D, 5D, 6D, 7D, 8D, 10D and 12D they the fittings are called pipe bends.

Production & Stock Range for Pipe Bends

| Product | Pipe Bends |

| Size | 1/2″ to 48″ |

| Wall Thickness (T) | T ≤ 120mm |

| Bending Radius (R) | R=3D, 5D, 6D, 8D, 7D, 10D, 12D |

| Bending Angle (θ) | 15°, 30°, 45°, 60°, 90°, 135°, 180° |

| Straight Length (L) | The length between two ends general from 300mm-1500mm |

| Type | Seamless, Welded, Fabricated |

| Standards | ANSI, ASME, ISO, JIS and DIN |

| Quality | Minimum Wall Thinning Rate & Ovality, No Wrinkles |

| Test Certificate | EN 10204 3.1 |

What is the Weight Calculation Formula for Pipe Bends?

Weight in kgs = 0.0433 ( D – T ) TRθ / 100000 + L

- D = Outside diameter

- T = Thickness in mm

- R = Bend radius

- θ = Bend angle

- L = Weight of double sides straight length

Various Materials & Grades of Steel Pipe Bends

- Stainless Steel Pipe Bend: ASTM A 403 WP TP304/L, 316/L, 316Ti, 309, 310, 317L, 321, 347, 904L

- Duplex Steel Pipe Bend: ASTM A 815 UNS S31803, S32760, S31500

- Alloy Steel Pipe Bend: ASTM A 234 WP-P5, P9, P11, P12, P21, P22 & P91

- Carbon Steel Pipe Bend: ASTM A 234 WPB

- Low Temperature Carbon Steel Pipe Bend: ASTM A420 WPL6

- Nickel Alloy Pipe Bend : Standard: ASTM / ASME SB 336 Hastelloy C 276 Bend, Nickel 200 Bend, Nickel 201 Bend, Monel 400 Bend, Alloy 20 Bend, Inconel 825 Bend, Inconel 600 Bend, Inconel 601 Bend, Inconel 625 Bend

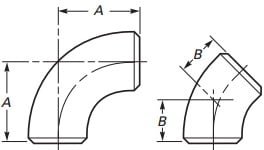

Dimensions of ASME B16.9 3D Elbows

- A 3D pipe bending is a pipe bend that the bend radius is 3 times the pipe outside diameter.

| Nominal Size | Outside Diameter at Bevel | Center to End | Center to End |

| NPS | mm. | 90-deg Elbows | 45-deg Elbows |

| in, | A | B | |

| mm. | mm. | ||

| in. | in. | ||

| 3/4 | 26.7 | 57 | 24 |

| 1.05 | 2.25 | 0.94 | |

| 1 | 33.4 | 76 | 31 |

| 1.32 | 3 | 1.25 | |

| 1 1/4 | 42.2 | 95 | 39 |

| 1.66 | 3.75 | 1.56 | |

| 1 1/2 | 48.3 | 114 | 47 |

| 1.9 | 4.5 | 1.88 | |

| 2 | 60.3 | 152 | 63 |

| 2.38 | 6 | 2.5 | |

| 2 1/2 | 73 | 190 | 79 |

| 2.88 | 7.5 | 3.12 | |

| 3 | 88.9 | 229 | 95 |

| 3.5 | 9 | 3.75 | |

| 3 1/2 | 101.6 | 267 | 111 |

| 4 | 10.5 | 4.38 | |

| 4 | 114.3 | 305 | 127 |

| 4.5 | 12 | 5 | |

| 5 | 141.3 | 381 | 157 |

| 5.56 | 15 | 6.19 | |

| 6 | 168.3 | 457 | 189 |

| 6.62 | 18 | 7.44 | |

| 8 | 219.1 | 610 | 252 |

| 8.62 | 24 | 9.94 | |

| 10 | 273 | 762 | 316 |

| 10.75 | 30 | 12.44 | |

| 12 | 323.8 | 914 | 378 |

| 12.75 | 36 | 14.88 | |

| 14 | 355.6 | 1067 | 441 |

| 14 | 42 | 17.38 | |

| 16 | 406.4 | 1219 | 505 |

| 16 | 48 | 19.88 | |

| 18 | 457 | 1372 | 568 |

| 18 | 54 | 22.38 | |

| 20 | 508 | 1524 | 632 |

| 20 | 60 | 24.88 | |

| 22 | 559 | 1676 | 694 |

| 22 | 66 | 27.31 | |

| 24 | 610 | 1829 | 757 |

| 24 | 72 | 29.81 | |

| 26 | 660 | 1981 | 821 |

| 26 | 78 | 32.31 | |

| 28 | 711 | 2134 | 883 |

| 28 | 84 | 34.75 | |

| 30 | 762 | 2286 | 964 |

| 30 | 90 | 37.25 | |

| 32 | 813 | 2438 | 1010 |

| 32 | 96 | 39.75 | |

| 34 | 864 | 2591 | 1073 |

| 34 | 102 | 42.25 | |

| 36 | 914 | 2743 | 1135 |

| 36 | 108 | 44.69 | |

| 38 | 965 | 2896 | 1200 |

| 38 | 114 | 47.25 | |

| 40 | 1016 | 3048 | 1264 |

| 40 | 120 | 49.75 | |

| 42 | 1067 | 3200 | 1326 |

| 42 | 126 | 52.19 | |

| 44 | 1118 | 3353 | 1389 |

| 44 | 132 | 54.69 | |

| 46 | 1168 | 3505 | 1453 |

| 46 | 138 | 57.19 | |

| 48 | 1219 | 3658 | 1516 |

| 48 | 144 | 59.69 |