Electropolish Pipe & Tube Manufacturers, Suppliers, Stockist – Stainless Steel Tube with Electro Polish & Mechanical Polish | Stainless Steel High Purity Tube

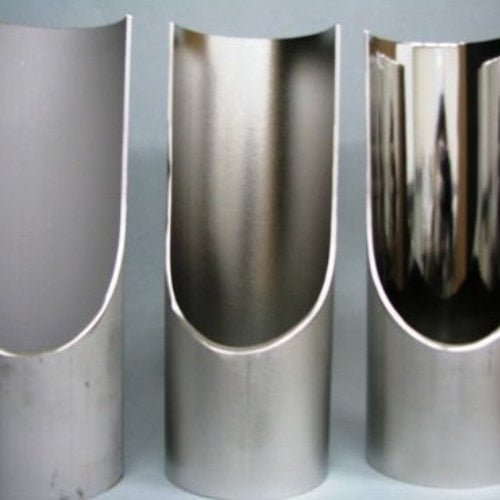

- Metallica specializes in Electro-polishing (EP) and Mechanical Polishing (MP) services on round stainless steel pipes, tubes and fittings. Electropolished or mechanical polished pipes and tubes are mainly produced in grade SS304/304L, and SS316L, which are both widely used for dairy, brewery and food processing applications.

- We are manufacturers and suppliers of all types seamless and welded electropolished pipes in sizes range of 6.0mm to 253 OD, in wall thickness upto 10mm. The most popular size range of the electroploshed stainless steel tubes is between O.D 6 mm (1/4″) to O.D 50 mm (2″), and we can supply the high purity tubes or electropolished tubes with random length or fixed length 1 meter to 6 meters.

- We are manufacturing electropolished pipes or mechanical polished pipe by following a stringent quality control program and standards which assure good surface and close dimensional tolerances. We are a global industry leading provider of stainless steel 304 and stainless steel 316L electropolished pipes and have obtained ASME Quality and ISO 9001:2015 Certifications. In addition to being a world class stainless steel pipe manufacturer, we are an authorized dealer of ISMT and Jindal for stock and supply of carbon steel and alloy steel pipes.

- All our electropolished pipe and tube products are supplied with 3.1 specific test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of ordering. Metallica makes it easy for you to source top quality electropolished pipes at the lowest prices.

- We specialize in providing deliveries to your factory directly from our warehouse or our principal suppliers. For immediate deliveries of electropolished pipes, our inventory is stocked in around 5 warehouses in Kalamboli and 3 warehouses in Mumbai. With a team of over 50 people dedicated for deliveries and response to our esteemed customers, we can offer the best service. At the same time, we are also committed to offer best quality products and most competitive prices to our customers.

- Electropolished tubes, also known as high purity tubing, are manufactured in accordance with ASTM A270 standards, making it ideal for ultra high purity applications. By electropolishing the ID surface anomalies are minimized, providing a ultra-smooth, corrosion resistant, chromium enriched surface where contaminants cannot hide.

Electropolished Pipes Specifications, Stock & Production Range

| Product | Electropolished Tubes / Hgh Purity Tubing |

| Type | Seamless, Welded |

| Materials | Stainless Steel, Duplex |

| Size |

|

| Thickness | 0.5 mm to 10 mm |

| Technology | Cold Drawn, Extruded, Cold Finished, Heat Treated |

| Surface | BA, EP, MP, 3PE, FBE |

| Certification | EN 10204 3.1 |

| Prices | info@metallicametals.com | +918928722715 |

- Email Us on info@metallicametals.com for best prices on various types of Electropolished Pipes such as SS 304 Electropolished Pipes, SS 316 Electropolished Pipes, Duplex Electropolished Pipes, SS 304 High Purity Tubes, SS 316 High Purity Tubes, Duplex High Purity Tubes

- Marking: Heat Number, Size, Grade, Manufacturing Spec., Commodity Name or as per customer request

About Electropolished Tubes

Electropolished Tubes | High Purity Stainless Steel Tubing | Seamless Tubes

Electropolished tubes or high purity tubes are widely used in industries where high purity, high cleanliness, and high performance are critical. Some of the most demanding applications for electropolished tubes are in semiconductor industry, pharmaceuticals, laboratory engineering, high purity gas industry, and more. As one of the top quality India precision stainless steel tube manufacturers, Metallica produces and supplies electropolished tubes in a wide range of metric sizes and imperial sizes. Our customers include many respected companies in India and overseas.

Materials Used for Manufacturing Electropolished or High Purity Tubes

AISI 304/304L and AISI 316L stainless steel high purity tubing is the most popular choice among piping contractors. We also produce electropolished tubes or high purity tubes in other materials on customer’s requests. We produce and supply high purity tubing in stainless steel of EN/DIN steel grades and AISI/UNS steel grades as below:

- AISI/UNS Steel Grades: AISI 316, AISI 316L, AISI 304, AISI 304L, AISI 316Ti, Duplex 2205, UNS S32205, UNS S31803

- EN DIN Steel Grades: 1.4401, 1.4404, 1.4435, 1.4301, 1.4307, 1.4462

Surface Finish for Electropolished Tubes

- Bright Annealed Tubes– The surface roughness of bright annealed stainless steel tube is between Ra 0.4μm to Ra 0.8μm upon customers’ request.

- Mechanically Polished Tubes – Outside diameter polished and inside diameter polished. We can supply high purity stainless tubing with mechanical polished surface on outside diameter and inside diameter, with roughness Ra 0.6 μm to 0.8 μm.

- EP or Electro-polished Tubes – EP stainless steel tubes are mostly ultra high purity tubes. The roughness can be as good as Ra 0.25 μm or better.

Manufacturing Process of Electropolished or High Purity Tubes

- Our high purity stainless steel tubing is mostly produced through specially rolled and bright annealed process, then with mechanical polishing or electro polishing depends on the application requirements. Normally the stainless steel tubes are ultrasonically cleaned and dried; and for ultra high purity stainless tubing, after ultrasonically cleaning, it will be washed, rinsed, purged with filtered hot Nitrogen and dried upon customer’s request or upon the application requirements.

Stainless Steel Electropolished or High Purity Tubes

- Stainless Steel 304/304L Electropolished Tubes

- Stainless Steel 304/304L High Purity Tubes

- Stainless Steel 316L Electropolished Tubes

- Stainless Steel 316L High Purity Tubes

- Stainless Steel 316Ti Electropolished Tubes

- Stainless Steel 316Ti High Purity Tubes

- Stainless Steel 321/321H High Purity Tubes

- Stainless Steel 347/347H High Purity Tubes

- Stainless Steel 904L High Purity Tubes

Duplex Steel High Purity Tubes

- Duplex Steel S31803 / S32205 High Purity Tubes

- Super Duplex Steel S32750/ S32760 High Purity Tubes

Testing & Inspection of Electropolished/High Purity Tubes

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Electropolished or Mechanical Polished Tubes

Prices for electropolished pipe products are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy pipes is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of seamless and welded EP/MP/BA pipe products, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided – Domestic Sales or Export of Electropolished Pipes

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Terms for Electropolished Pipes

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Electropolished Pipes

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Electropolished or High Purity Tubes

- For Mechanically Polished or Bright annealed (BA) high purity tubing, every tube will be marked with manufacturer name or brand, material steel grade, production standard, dimension (OD x WT x Length), and heat number. While for EP ultra high purity tubing, the above markings will be on the packing bags or with a label.

- For Mechanically polished tubing and BA high purity tubing, each end of tube is capped with plastic tube cap, and then every tube tube is packed individually in a single polyethylene bag; while for EP ultra high purity stainless steel tubing, each tube will be capped in the ends, and every tube will be packed in double polyethylene bags.

Suppliers of Electropolished/High Purity Tubes in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Exporters of Electropolished/High Purity Tubes

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu