Slip On Flange Manufacturers, Suppliers, Stockist – ASME/ANSI Standard Slip On Flange, DIN Standard Slip On Flanges, EN Standard Slip On Flange Factory

- Metallica specializes in manufacturing the best quality slip on flanges in varieties of specifications, grades, materials and sizes. We specialize in producing slip on flanges as per various dimensional standards including ANSI/ASME B16.5, ANSI/ASME B16.47 Series A (MSS SP-44), ANSI/ASME B16.47 Series B (API 605), ANSI/ASME B16.36, ANSI/ASME B16.48 (API 590). In addition to ANSI and ASME standards, we can also produce slip on flanges as per EN, BS, and DIN standards.

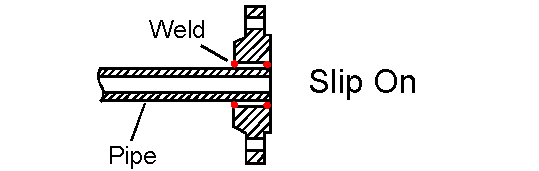

- Slip on flanges are probably the most common type of flanges in the industry and are ideal for lower pressure applications. Slip on flanges as the name suggests, are slipped over the pipe and welded (usually both inside and outside) to provide strength and prevent leakage. Slip on flanges are at the low cost end of the scale, and do not require high accuracy when cutting the pipe to length. These slip on can sometimes have a boss or hub, and can be made with a bore to suit either pipe or tube. It is fabricated with an inside diameter that is bigger than the pipe’s outside distance across. These connections are associated with the pipe by means of filet weld at the top and base of the flange.

- Slip on pipe flanges are used with a raised or flat face. At the time of raised face, the standard height would be 1/16″ for slip on pipe flanges under 400# while for slip on pipe flanges of 400#, the standard height would be 1/4″. The slip on pipe flanges include materials carbon steel slip-on pipe flanges, stainless steel slip on pipe flanges and alloy steel slip on pipe flanges available in various class such as 150 LBS, 300 LBS, 600 LBS, 900 LBS.

- We can also produce reducing type of slip on flange, where in case of a larger (say a 12″) slip on flange blank – instead of the Center (pipe) hole being cut out (or drilled out) for 12″ pipe it is cut out for a 6″ (or some other size) pipe. The slip on reducing flange is basically used for reducing the line size where space limitations restrict the use of a weld neck flange and reducer combination. The use of the slip on reducing type flange is generally preferred where the flow direction is from the smaller size into the larger size.

Product & Supply Range of Slip On Flanges

| Product | Slip On Flange |

| Size | 1/2″ (DN15) ~ 60″ (DN1500) |

| Flange Face | Raised Face(RF), Flat Face(FF), Ring Type Joint(RTJ), T&G |

| Pressure Rating | 150#-2500# (PN6-PN40) |

| Standard | ASME/ANSI, EN, DIN, BS |

| Test Certificate | EN 10204 3.1 |

Manufacturing Standards for Producing Slip On Flanges

ANSI/ASME Flange

- ANSI/ASME B16.5, ANSI/ASME B16.47 Series A (MSS SP-44), ANSI/ASME B16.47 Series B (API 605), ANSI/ASME B16.36, ANSI/ASME B16.48 (API 590)

BS Flanges

- BS10 Table D, E, F, H, J, K, R, S, T, BS4504 Code 101, 105, 111, 112, 113, BS1042

DIN Flanges

- DIN2527, DIN2573, DIN2576, DIN2502, DIN2503, DIN2543, DIN2544, DIN2545, DIN2630, DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2628, DIN2629, DIN2627, DIN2641, DIN2642, DIN2652, DIN2653, DIN2655, DIN2656, DIN2673, DIN2674, DIN2675, DIN2676, DIN2558, DIN2561, DIN2565, DIN2566, DIN2567, DIN2568, DIN2569, DIN28115, DIN86029, DIN86030

EN Flanges: EN 1092-1

- Type No.: Type 01 Plate Flange (slip on) for Welding, Type 02 Loose Plate Flanges with Weld On Plate Collar or for lapped pipe end, Type 04 Loose Plate Flanges with Weld Neck Collar, Type 05 Blind Flange, Type 11 Weld Neck Flange, Type 12 Hubbed Slip On Flanges for Welding, Type 13 Hubbed Threaded Flanges, Type 21 Integral Flange, Type 32 Weld on Plate Collar, Type 33 Lapped Pipe End, Type 34 Weld neck Collar, Type 35 Welding Neck, Type 36 Pressed collar with long neck, Type 37 Pressed Collar

When Do We Use of Slip on Flanges Over Other Types of Flanges?

- Unlike the socketweld flange, the slip-on flange allows the pipe to be inserted completely through its hub opening. Two welds are made to secure the flange to the pipe. One fillet weld is made at the hub of the flange, and the second weld is made at the inside diameter of the flange near the flange face.

- The slip-on flange is a preferred flange by some contractors because of its initial lower cost, the reduced need for cut length accuracy and the reduction in end prep time. However, the final installed cost is probably not much less than that of a weld-neck flange.

- The strength of a slipon flange under internal pressure is about 40% less than that of a weld-neck flange, and the fatigue rate is about 66% less. The slipon flange is not approved above Class 1500.

Materials for Manufacturing Slip On Flanges

- Carbon Steel: ASTM A105

- Low-Temperature: ASTM A350 LF1 LF2 CL1/CL2, LF3 CL1/CL2.

- Stainless Steel: ASTM A182 F304/304L, F316/316L, F321

- Alloy Steel: ASTM F1 F5 F9, F11, F91

- Pipeline Steel: A694 F42 F52 F60 F65

- Special Alloys: Nickel Alloys, Inconel, Monel, Hastelloy, Titanium, Aluminium, Copper Nickel

Types of Flanges –What are the Various Types of Flanges?

A flange can be characterized and classified in various ways such as:

-Types of Connection

-Flange facing Types

-Pressure Temperature Ratings

-Material Types

The standard type of steel flanges mostly used are:

- Welding Neck Flange: This type of flange has a neck that is welded to the end of pipes. It is used for high pressure applications to reduce the concentration of stress. Generally machined from a forging, these flanges are typically butt welded to a pipe. Weld-neck flanges have a higher life expectancy than slip-on flanges under duress.

- Slip On Flange: Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for many users. These pipe flanges slip over the pipe. They’re manufactured with an inside diameter that is slightly bigger than the pipe’s outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

- Socket Weld Flange: A socket weld flange has a female socket in which pipe is fitted. Fillet welding is done from outside on the pipe. The socket welding flange is similar to a slip-on flange except it has a bore and a counter bore dimension. The counter bore is slightly larger than the O.D. of the matching pipe, allowing the pipe to be inserted into the flange similar to a slip-on flange. The diameter of the smaller bore is the same as the I.D. of the matching pipe A restriction is built into the bottom of the bore which sets as a shoulder for the pipe to rest on. When using a socket weld flange, the inner diameter needs to be the same as the inner diameter of the pipe. The socket flange is only suitable for pipes with a nominal diameter of 150 or less.

- Lap Joint Flange: Lap Joint Flanges (LJ Flanges) are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges. Lap joint flange is having two components, a stub end, and a loose backing flange. Stub end is butt welded to the pipe and Backing flange freely move over the pipe. The backing flange can be of different material than stub material and normally of the carbon steel to save the cost. Lap flange is used where frequent dismantling is required, and space is constrained. The lap joint flange is practically identical to a slip-on flange except it has a radius at the intersection of the bore and flange face. The lap joint flange is practically identical to a slip-on flange except it has a radius at the intersection of the bore and flange face. This radius is necessary to have the flange accommodate a lap joint stub end. Normally, a lap joint flange and a lap joint stub end are mated together is an assembly system.

- Threaded Flange: Threaded Flanges are also known as screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications. This type of joint connection is speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water. Threaded (Screwed) flange is similar to the Slip-On flange, but the bore is threaded. Its chief merit is that it can be assembled without welding, explaining its use in low pressure services at ordinary atmospheric temperatures, and in highly explosive areas where welding create a hazard. Threaded flanges are not suitable for use where the temperature of the pipe changes sharply or the temperature is higher than 25°C and lower than -40°C.

- Blind Flange: A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened. The blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made. Blind Flanges are commonly used in petrochemical, pipe engineering, public services & water works. Blind pipe flanges are often used for high pressure applications.

In addition to the most used standard flanges, there are still a number of special steel flanges such as:

- Orifice Flange: Orifice flanges are used instead of the standard pipe flanges when orifice plate or flow nozzle is used. In other words, orifice flanges are used with orifice meters. The basic purpose for this is to measuring the flow rate of either gases or liquids in the respective pipeline.

- Long Welding Neck Flange: Long weld neck flange(LWN flange) is also call integral flange, it means a welding neck flange has a very long neck. Commonly, the welding neck flange has a tapered neck and a bevel end which is going to butt welding with the matching pipe. But the long weld neck flange, has a straight short pipe as the neck of a long weld neck flange.

- Weldoflange & Nipoflange: The Weldoflange and Nipoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. The 2 components are manufactured in one piece, and not welded. These flanges are primarily in Branch connections. Furthermore, they have an expanded range of special flanges, fittings and branch connections.

- Expander & Reducing Flange: Expanding and reducing flanges are used to increase or decrease the bore size of a pipeline. Expander and reducer flanges are a good alternative to butt weld reducers when the required pipeline bore reduction or increase is small (one or two sizes). For larger size changes, the use of buttweld fittings is recommended.

Selection of the Type of Flange Connection with Pipes

- Steel pipes can be connected to flanges by welding the pipe with the flange (welded connection, made with weld neck, socket weld, slip on and lap joint flanges) or by screwing the flange onto the pipe (threaded connection, made using threaded flanges).

- Welded connections are used for pipelines and piping systems featuring high pressures and temperatures, and diameters above 2 inches. Threaded connections are used for small diameter piping systems that are not subject to mechanical forces as expansion, vibration, contraction, oscillation (conditions that would crack the threaded joints). Let’s take a close look at the welded connections types.

Weld Neck Connection (Weld Neck Flanges)

- Weld-neck flanges have a tapered hub with a butt weld end that can be welded to a butt weld pipe. The quality of the welded joint should be examined by dye penetrant test (DP) or using radiography and/or ultrasounds (UT).

- The welded connection between a weld neck flange and a pipe features a good fatigue and mechanical stress performance.

Socket Weld Connection (Socket Weld Flanges)

- Socket weld flanges are most preferred for use in high pressure piping systems generally below 2 inches (DN 50).

- The pipe is fillet-welded to the hub of the socket weld flange. The quality of weld is of utmost importance in this kind of a flange connection, and appropriate inspection should be done before moving the system into operation.

Slip-On Connection (Slip On Flanges)

- Slip-on flanges are generally preferred to weld-neck flanges due to their lower cost and installation speed (and ease).

- The disadvantage of slip on flanges over weld neck flanges is that their strength is about 1/3 lower.

- Due to lower strength slip on flanges are typically used for low-pressure, non-critical services.

- The pipe is welded to both the hub and the bore of the flange. Slip-on flanges are used, generally, for pipe sizes greater than NPS 2¹⁄₂ (DN 65).

Lap Joint Connection (Lap Joint Flanges and Stub Ends)

- This type of connection is sometimes used for pipelines in high-cost materials (as stainless steel and nickel alloys) as it helps to reduce the overall cost of the required flanged connections.

- A lap joint connection is made by the combination of a stub end (which is the part welded to the pipe) and a backing flange, or lapped flange.

List of Top Manufacturers of Steel Flanges – CLICK HERE

We are manufacturer of high quality steel flanges and supply high quality flanges in both large and small quantities worldwide and offer you the best prices in the market.

Manufacturing Process for Steel Flanges

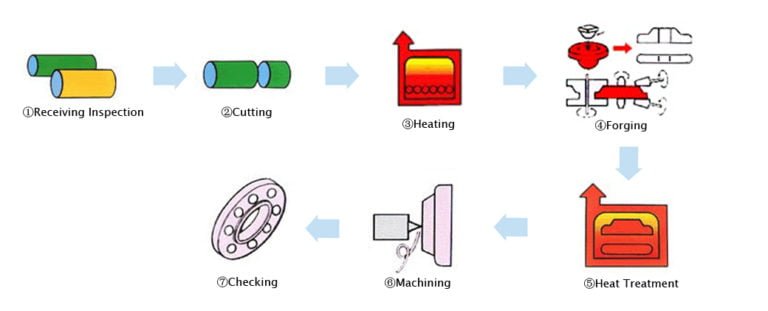

A flange is produced either by forging, casting, cutting, or rolling. We produce flanges mainly by forging, cutting, and rolling process.

Forged Flange Manufacturing Process

The forging process is usually composed of the following processes, namely, the selection of quality steel billet, heating, forming and cooling.

Flange Manufacturing Process

- Inspection of Raw Material – The key raw material for producing flanges is steel billets or hot rolled bars. All raw materials purchased are supplied with test reports as per EN 10204 3.1, with full traceability. It is the first compulsory step in the production process for flanges to guarantee good quality. The raw materials are re-tested inhouse for assurance on chemical composition, mechanical capacity and metallographic analysis.

- Cutting Raw Material – Correctly and strictly controlling cutting size and proportion can ensure adequate control on the cost.

- Heating – It is a very important step for flange quality. It is the necessary to record the heating temperature in details to avoid overheating. Overheating will destroy the structure of the metal and mechanical properties pf the raw materials.

- Forging – Forging process is divided into free forging and die forging. The forging time and strength of flange is different for different pressure class.

- Heat Treatment – The purpose of heat treatment is to eliminate the stress inside of flange so that the density is more evenly. Carefully recording the temperature of heat treatment and cooling time are the keys.

- Forging Blank Inspection – After the heat treatment process has been carried out, a sample of the lot is chosen to test the chemical composition and mechanical property again to ensure all items are qualified.

- Machining of Forged Blanks – In the machining process, the inspection is carried out along with the processing, so that to guarantee each part of flange is qualified. Machining is undertaken on CNC and/or lathe machines.

- Finishing Goods Inspection – Finished products will be checked 100% before delivery to ensure the goods are perfect as per ASME, EN or customer standards.

- Documentation – The whole production process and quality checks at different levels is documented as per standard operation procedure under ISO compliance. It is the guarantee for good quality.

- Test Certificate: Since we are a ISO and PED certified manufacturer, we can issue test certificate as per EN 10204 3.1 for all the goods at the time of delivery and inspection.

- Packing: All forgings and flanges are packed in wooden crates or box or pallets to ensure secure movement of goods.

Plate Cut Flanges Manufacturing Process

- The process here is relatively simple, with the key raw material being hot rolled plates. This process is mainly used for producing slip on plate flanges and blind flanges for lower thickness. All plates procured are accompanied with tested certificates as per EN 10204 3.1.

- Circles are cut from plates.

- Heat treatment is not involved in this process of manufacturing flanges.

- Drilling and machining is done on circles to achieve the desired dimensions.

- Goods are visually inspected and marked with relevant standards.