Stainless Steel High Pressure Pipes and Tubes, Suppliers, Manufacturers – ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A789 High Pressure Pipe

| TP304/1.4301 Stainless Steel High Pressure Tubes | TP321/1.4541 Stainless Steel High Pressure Tubes |

| TP304L/1.4307 Stainless Steel High Pressure Tubes | TP317L/1.4449 Stainless Steel High Pressure Tubes |

| TP304H/1.4948 Stainless Steel High Pressure Tubes | TP347H/1.4912 Stainless Steel High Pressure Tubes |

| TP316/1.4401 Stainless Steel High Pressure Tubes | TP309S/1.4833 Stainless Steel High Pressure Tubes |

| TP316L/1.4404 Stainless Steel High Pressure Tubes | TP310S/1.4845 Stainless Steel High Pressure Tubes |

| TP316Ti/1.4571 Stainless Steel High Pressure Tubes | 904L Stainless Steel High Pressure Tubes |

- We specialize in manufacturing stainless steel high pressure pipe/tubes in straight lengths of up to 30 meters, or as U-bends in a size range of 3/16” (4.76 mm) to 4” (101.6 mm) in wall thickness upto 15mm. We can produce seamless and welded stainless steel high pressure pipe/tubes in a wide range of grades and sizes. Our manufacturing range for stainless steel high pressure pipe/tubes include pipe/tubes produced from stainless steel – 304/304H, 309S/309H, 321/321H, 316/316H, 347/347H.

- Boilers that operate higher than 15 psig are called “high-pressure” boilers. High-pressure tubes are characterized by high yield strength and high tensile strength in combination with high elongation. The pressure resistance is guaranteed by the very smooth inside surface. An autofrettage treatment prolongs the cycle fatigue behavior. Seamless high-pressure tubes for a variety of high-pressure applications using liquid or gas as the pressure medium, such as hydraulic installations, test benches and water-jet cutting equipment. All our tubes are 100% quality tested, which include chemical testing, mechanical testing as well as hydro testing. All stainless steel high pressure pipes are heat treated, solution annealed, and pass hydrostatic test and ultrasonic test.

- Stainless steel high pressure tubes are used to produce seamless tubing for water boilers and superheaters, boiler drums, collectors, pumps and pressure vessels for elevated pressure service, and steam turbine heavy shafts with diameter exceeding 2 meters and weighing more than 100 mt.

- Applications of stainless steel high pressure pipe/tubes: – A stainless steel high pressure pipe/tube is a device used to transfer heat between two or more fluids. Power generation and petrochemical plants, which use all product forms. Steam turbines require large forgings and castings, whereas pressure vessels, boilers and piping systems require tubes, pipes, plates and fittings. In addition to high creep strength, other material properties like hardenability, corrosion resistance, and weldability are also important. The relative importance of these properties depends on the specific application. For example, large turbine rotors require steels with good hardenability, whereas power plant tubing and piping must have good weldability. Even so, the alloys used in these different applications employ the same mechanisms to improve creep strength. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a high pressure is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive high pressure that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

- We are manufacturing seamless and welded stainless steel high pressure tubes by following a stringent quality control program and standards which assure good surface and close dimensional tolerances. We are a global industry leading provider of carbon steel tube, alloy steel tube and stainless steel high pressure tube solutions and have obtained ASME Quality and ISO 9001:2015 Certifications. In addition to being a world class tubing manufacturer, we are an authorized dealer of ISMT and Jindal for stock and supply of carbon steel and alloy steel tubes.

- All our stainless steel high pressure tube products are supplied with 3.1 specific test certificates, according to EN 10204. Certification according to 3.2 can be agreed at the time of ordering. Metallica makes it easy for you to source top quality stainless steel high pressure tubes at the lowest prices.

- We specialize in providing deliveries to your factory directly from our warehouse or our principal suppliers. For immediate deliveries of tubes, our inventory is stocked in around 5 warehouses in Kalamboli and 3 warehouses in Mumbai. With a team of over 50 people dedicated for deliveries and response to our esteemed customers, we can offer the best service. At the same time, we are also committed to offer best quality products and most competitive prices to our customers.

Manufacturing Process for Stainless Steel High Pressure Pipe/Tubes

The stainless steel high pressure pipe/tubes are manufactured by piercing process followed by pilgering/drawing. Our facilities are equipped with all the machines required to cover the process with a high quality results (piercing, pilger machines, draw benches, straightening machine, degreasing facility and solution annealing furnace).

All seamless stainless steel high pressure pipe/tubes are manufactured by cold drawing and cold rolling process followed by annealing, straightening and testing. The tolerance of tubes produced by us in line with ASME/ASTM & EN Standards. We promise each stainless steel high pressure pipe/tube that we deliver to our client will be the best in quality. All shipments include a full Test Certificate showing all required test results and verifying compliance with the order requirements.

- Cold Rolling – Tube rolling uses compression to reduce the size of seamless stainless steel high pressure pipe/tubes. It utilizes one or two sets of rolls with constant cross-section grooves on the circumference of the tube. The rolls are driven by rack and pinion gears of different radii along profiled cams, completing multiple 360º rotations around the tube. Tube rolling is a very precise method of reducing very thin walled and/or smaller diameter tubes, and is often used as the final cold working step. By rolling, we’re able to achieve exceptional control over dimensional tolerances and surface finish while also minimizing material loss and improving the metal’s microstructure.

- Cold Drawing – Cold drawing reduces the diameter by pulling the tube through a die that is smaller than the tube. In order to fit the tube into the die, one end is swaged thereby reducing the diameter of the leading end before drawing. Next, the narrowed end is passed through the die and clamped to a drawing trolley which pulls the tube through the die.

- Annealing – Annealing is used to soften the metal before further cold working or fabrication processes, and improves the overall metallurgical microstructure of the tube. During tube reduction or cold drawing, it can become hard and somewhat brittle. To be able to draw the tube again, stresses formed during cold working need to be removed to return the material to its normal state. During annealing the tube is heated to a controlled pressure and soak time. Through this process the tube remains in shape, but the grains in the structure of the tube reform into a regular unstressed pattern. The resulting annealed tube is softer and suitable for redrawing

- Straightening – Drawing and annealing generally results in some degree of bowing, producing a slight bend in the tubing. In order to make the tubes straight, we use multiple roll mechanical straighteners to implement this procedure, Straightening can introduce slight changes to the size and mechanical properties of the tubing, so these aspects are very carefully controlled during the process.

- Inspection and Tests – At each manufacturing stage, stainless steel high pressure pipe/tubes are submitted to a visual and dimensional inspection. They are also submitted to Eddy current test (straight tubes) or, if requested, to other non destructive tests in accordance with the requirements of the standards. Mechanical tests, along with flaring and flattening tests, are performed on samples of each order as per the reference standards. We inspect all lots of stainless steel high pressure tubing before shipment to ensure that every aspect of the customer’s order has been met. Our in-house inspection and tests capabilities include:

- Chemical Composition Test

- Visual inspection

- Dimensional inspection

- Surface roughness testing

- Eddy Current testing

- Hydrostatic pressure testing

- Destructive mechanical testing:

- Yield Strength

- Tensile Strength

- Elongation

- Hardness testing

- Bending, flattening, and flaring

Stainless Steel High Pressure Pipe/Tubes

Stainless Steel High Pressure Pipe/Tubes

Stainless Steel High Pressure Pipe/Tube Specifications, Stock & Production Range

| Product | High Pressure Pipe/Tubes |

| Type | Seamless, Welded, Finned |

| Standard | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A789 |

| Grade | 304/L, 316/L, 201, 202, 301, 347/H, 316Ti, 309S, 310S, Duplex, Super Duplex, 904L, 317L |

| Size | 3/16″ (4.76mm) to 4″ (101.6mm) |

| Length | Upto 30 Meters, Custom |

| Thickness | 0.5mm to 12.7mm |

| Technology | Hot Rolled, Cold Drawn, Extruded |

| Surface | A&P, BA, EP, PE, 3PE, FBE, Varnish, Anti Rust Oiled |

| Certification | EN 10204 3.1 |

| Prices | info@metallicametals.com | +918928722715 |

- Email Us on info@metallicametals.com for best prices on various types of Stainless Steel High Pressure Pipe/Tube, Duplex High Pressure Pipe/Tube, Super Duplex High Pressure Pipe/Tube, 321H High Pressure Pipe

- Marking: Heat Number, Size, Grade, Manufacturing Spec., Commodity Name or as per customer request

Chemical Composition of Stainless Steel High Pressure Pipe

| Chemical Composition % | |||||||||

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 201 (1Cr17Mn6Ni5N) | ≤0.15 | ≤1.0 | ≤5.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | — | ≤0.25 |

| 202 (1Cr18Mn8Ni5N) | ≤0.15 | ≤0.07 | ≤7.5 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | — | ≤0.25 |

| 304 0Cr18Ni9) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 304L (00Cr18Ni10) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 8.0-11.0 | 18.0-20.0 | — | — |

| 316 (0Cr17Ni12Mo2) | ≤0.08 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 316L (0Cr17Ni14Mo2) | ≤0.03 | ≤0.07 | ≤2.0 | ≤0.04 | ≤0.03 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 | — |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.04 | ≤0.03 | 9.0-12.0 | 17.0-19.0 | Ti≥5xC | |

| 409 | ≤0.08 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.5 | 10.5-11.7 | Ti6xC%≤0.70 | |

| 409L | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.5 | 10.5-11.7 | Ti8xC%≤0.70 | |

| 430 | ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 16.0-18.0 | |||

Impact of Various Alloying Elements on Stainless Steel

| Element | Effect on Stainless Steel |

| Chromium | Forms a passive film with oxygen that prevent the further diffusion of oxygen into the surface |

| Composition needs to contain at least 10.5% to be a stainless steel | |

| Nickel | Increases ductility and toughness. Increase corrosion resistance to acids |

| Additon creates non-magnetic structure | |

| Molybdenum | Increases pitting and crevice corrosin resistance. Increase resistance to chlorides |

| Copper | Increase corrosion resistance to sulfuric acid |

| Manganese | Substitute for nickel (200 series) |

| Titanium/Niobium | Ties up carbon and prevents inter-granular corrosion in welded zone of ferritic grades |

| Nitrogen | Increase strength and corrosion resistance in austenitic and duplex grades |

| Silicon | Improves resistance to high temperature scaling |

| Sulfur | Usually kept low excet for “free-machining” grades |

| Carbon | Usually kept low. Used in martensitic grades to increase strength and hardness |

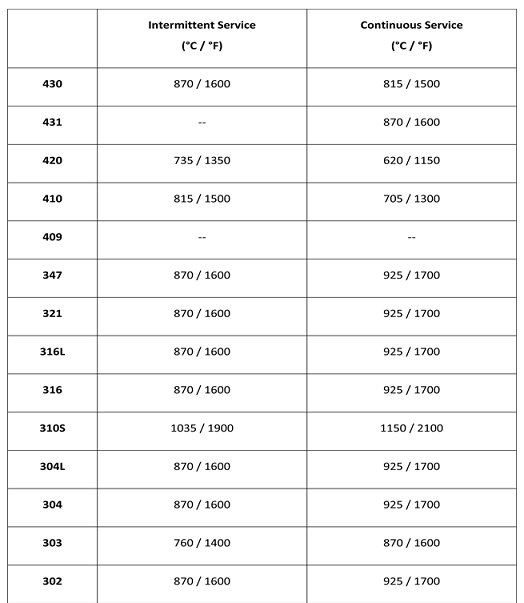

Maximum Optimum Temperatures of Stainless Steel Grades

Stainless steels have good strength and good resistance to corrosion and oxidation at elevated temperatures. Stainless steels are used at temperatures up to 1700° F for 304 and 316 and up to 2000 F for the high temperature stainless grade 309(S) and up to 2100° F for 310(S).

[Image Source: From Web]

Stainless Steel High Pressure Pipe/Tube

- Stainless Steel High Pressure 304/304L Pipe/Tube

- Stainless Steel High Pressure 304H Pipe/Tube

- Stainless Steel High Pressure 310/310S Pipe/Tube

- Stainless Steel High Pressure 316/316L Pipe/Tube

- Stainless Steel High Pressure 316Ti Pipe/Tube

- Stainless Steel High Pressure 317/317L Pipe/Tube

- Stainless Steel High Pressure 321/321H Pipe/Tube

- Stainless Steel High Pressure 347 Pipe/Tube

- Stainless Steel High Pressure 347H Pipe/Tube

- Stainless Steel High Pressure 410 Pipe/Tube

- Stainless Steel High Pressure 446 Pipe/Tube

- Stainless Steel High Pressure 904L Pipe/Tube

Alloy Steel High Pressure Pipe/Tube

- Alloy Steel T1 High Pressure Pipe/Tube

- Alloy Steel T2 High Pressure Pipe/Tube

- Alloy Steel T5/T5b/T5c High Pressure Pipe/Tube

- Alloy Steel T9 High Pressure Pipe/Tube

- Alloy Steel T11 High Pressure Pipe/Tube

- Alloy Steel T12 High Pressure Pipe/Tube

- Alloy Steel T22 High Pressure Pipe/Tube

- Alloy Steel T23 High Pressure Pipe/Tube

- Alloy Steel T91 High Pressure Pipe/Tube

Hastelloy High Temperature Pipe/Tube

- Hastelloy C22 High Pressure Pipe/Tube

- Hastelloy C276 High Pressure Pipe/Tube

- Hastelloy B2 High Pressure Pipe/Tube

- Hastelloy B3 High Pressure Pipe/Tube

- Hastelloy X High Pressure Pipe/Tube

Nickel High Pressure Pipe/Tube

- Nickel 200 High Pressure Pipe/Tube

- Nickel 201 High Pressure Pipe/Tube

Special Alloy High Pressure Pipe/Tube

- Alloy 20 High Pressure Pipe/Tube

- SMO 254 High Pressure Pipe/Tube

- AISI 4130 High Pressure Pipe/Tube

- Aluminum High Pressure Pipe/Tube

- Copper High Pressure Pipe/Tube

- Brass High Pressure Pipe/Tube

Duplex Steel High Pressure Pipe/Tube

- Duplex Steel S31803 / S32205 High Pressure Pipe/Tube

- Super Duplex Steel S32750/ S32760 High Pressure Pipe/Tube

Titanium High Pressure Pipe/Tube

- Titanium Gr 2 High Pressure Pipe/Tube

- Titanium Gr 5 High Pressure Pipe/Tube

Inconel High Pressure Pipe/Tube

- Inconel 600 High Pressure Pipe/Tube

- Inconel 601 High Pressure Pipe/Tube

- Inconel 625 High Pressure Pipe/Tube

- Inconel 718 High Pressure Pipe/Tube

Incoloy High Pressure Pipe/Tube

- Incoloy 800 / 800H / 800HT High Pressure Pipe/Tube

- Incoloy 825 High Pressure Pipe/Tube

- Incoloy 925 High Pressure Pipe/Tube

- Incoloy 330/ SS 330/ Ra 330 High Pressure Pipe/Tube

Monel High Pressure Pipe/Tube

- Monel 400 High Pressure Pipe/Tube

- Monel K500 High Pressure Pipe/Tube

Cupro Nickel High Pressure Pipe/Tube

- Cupro Nickel 90 / 10 High Pressure Pipe/Tube

- Cupro Nickel 70 / 30 High Pressure Pipe/Tube

Carbon Steel High Pressure Pipe/Tube

- ASTM A192 / ASME SA192 High Pressure Pipe/Tube

- ASTM A179 / ASME SA179 High Pressure Pipe/Tube

- ASTM A210 / ASME SA210 GR. A1 High Pressure Pipe/Tube

- ASTM A210 / ASME SA210 GR. C High Pressure Pipe/Tube

Various Grades of Stainless Steel

| Austenitic Stainless Steels | |

| 301 | High strength for roll formed structural components |

| 304, 304L, 304H | Standard 18/8 grades |

| 310, 310S, 310H | High temperature resistant grades |

| 316, 316L, 316H | Improved resistance to pitting corrosion in chloride environments |

| 321, 321H, 347 | Stabilized grades for heavy section welding and high temperature applications |

| 904L | High resistance to general corrosion, pitting and stress corrosion cracking |

| Ferritic Stainless Steels | |

| 409 | Automotive exhaust grade – weld stabilized |

| 430, 430F | Resistant to mildly corrosive environments |

| 439 | Resistant to mildly corrosive environments – weld stabilized |

| 444 | A ferritic alternative to grade 316 / 316L – weld stabilized |

| Duplex Stainless Steels | |

| 2101 | Lean duplex – economical alternative to 304 and 316 |

| 2304 | Duplex alternative to grade 316 |

| 2205 | Standard duplex stainless steel – high resistance to pitting and stress corrosion |

| 2507 | Super duplex with very high resistance to pitting and stress corrosion |

| Martensitic Stainless Steels | |

| 410 | Standard martensitic grade for low-duty hardened applications |

| 416 | Free-machining bar grade |

| 420 | Higher hardness martensitic grade for cutlery, cutting tools and dies |

| 431 | High hardness and toughness grade, primarily for shafting |

| 440A, 440B, 440C | Very high hardness grades used in cutting tools |

| Precipitation Hardening Stainless Steel | |

| 630 | (17-4PH) High strength shafting grade |

Testing & Inspection of Stainless Steel High Pressure Pipe/Tubes

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Stainless Steel High Pressure Pipe/Tubes

Prices for stainless steel high pressure pipe/tube or tubing products are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy high pressure pipe/tubes is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminum, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of seamless and welded stainless steel high pressure pipe/tube products, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided – Domestic Sales or Export of Stainless Steel High Pressure Pipe/Tubes

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Terms for Stainless Steel High Pressure Pipe/Tubes

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Stainless Steel High Pressure Pipe/Tubes

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Stainless Steel High Pressure Pipe/Tubes

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

Suppliers of Stainless Steel High Pressure Pipe/Tubes in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Exporters of Stainless Steel High Pressure Pipe/Tubes

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu