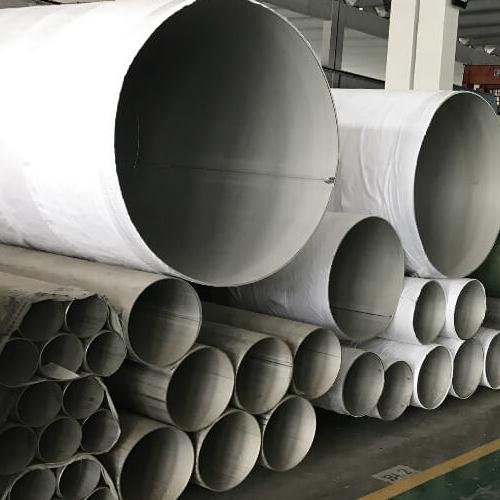

One of the largest stockholder and supplier of stainless steel Duplex 2205 seamless pipes used for producing high temperature heat exchangers. All our tubes are 100% quality tested, which include chemical testing, mechanical testing as well as hydro testing.

A heat exchanger is a device used to transfer heat between two or more fluids. Heat exchangers are used in both cooling and heating processes.[1] The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact.[2] They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

Source: Wikipedia

- Large Scale Enterprise – Metallica is biggest stock holding, manufacturing and processing company of SS Duplex 2205 seamless pipes in India. Our large volume production, sales and purchase enables us to offer our products at the most competitive prices in the industry.

- Testing of Stainless Steel Duplex 2205 Seamless Pipes– All SS Duplex 2205 seamless pipes are subjected to hydrostatic test, eddy current test, chemical and mechanical tests during the various stages of production.

- Marking & Packing of Stainless Steel Duplex 2205 Seamless Pipes – Marking on all pipes is as per the predefined rules in the specification.

- Test Certificates & Inspection of SS Duplex 2205 Seamless Pipes – All our pipes are supplied with Mill test Reports, as per EN 10204 3.1. We can also allow third party inspection of all our products before delivery.

- We have own QC team to control the quality to meet particular standard strictly

- Short Lead Times – We can offer AISI Duplex 2205, 1.4462, UNS S31803/S32205 seamless pipes with shortest delivery time.

- We can produce either standard or non-standard of the stainless steel Duplex 2205 seamless pipes.

What is Duplex 2205 Stainless Steel?

Duplex 2205 is a two-phase ferritic/austenitic – structures are approximately 50/50 austenite and ferrite and physical properties are a combination of the ferritic and the austenitic grades. It is the most widely used nitrogen enhanced duplex stainless steel grade and is characterized by high yield strength, double that of the standard austenitic stainless steel grades.It was developed to combat common corrosion problems encountered with the 300 series stainless steels. It demonstrates good fatigue strength, as well as outstanding resistance to stress-corrosion cracking, crevice, pitting, erosion and general corrosion in severe environments. Duplex Steel 2205 is not generally suitable for use at temperatures above 300°C as it suffers from precipitation of brittle micro-constituents, nor below -50°C because of its ductile-to-brittle-transition. It finds applications due to both excellent corrosion resistance and high strength. “Duplex” describes a family of stainless steels that are neither fully austenitic, like 304 stainless, nor purely ferritic, like 430.

Duplex family consists of:

- Lean Duplex SS – lower nickel and no molybdenum – 2101, 2102, 2202, 2304

- Duplex SS – higher nickel and molybdenum – 2205, 2003, 2404

- Super Duplex – 25Chromium and higher nickel and molybdenum “plus” – 2507, 255 and Z100

- Hyper Duplex – More Cr, Ni, Mo and N – 2707

Manufacturing Range for Stainless Steel Duplex 2205, 1.4462, UNS S31803/S32205 Seamless or Welded Stainless Steel Pipes

| Product | ASTM A312 Duplex 2205, 1.4462, UNS S31803/S32205 Stainless Steel Pipes |

| Specification | ASTM A312 / A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes |

| Type | Seamless & Welded |

| Size Range | Size: 1/8” to 24” (10.3mm to 610mm) – Seamless |

| Size:1/8” to 36” (10.3mm to 914mm) – Welded |

| 1/8” OD to 6” OD |

| Thickness | 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXH |

| Wall Thickness: 1mm to 60mm |

| Length | 6 Meter, Custom Lengths |

| Other Grades | TP304, TP304L, TP304LN, TP316, TP316L, TP316LN, TP317, TP317/317L, TP321, TP347, TP310S |

| Test Certificates | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| ASTM Reference Standards | - A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels.

- A370 Test Methods and Definitions for Mechanical Testing of Steel Products.

- A480 A480M Specification for general requirements for Flat-rolled stainless and Heat-Resisting steel plate, sheet, and strip.

- A632 Specification for Seamless and welded austenitic stainless-steel tubing (small-diameter) for general service.

- A1016 A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless-Steel Tubes.

- E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

|

| Testing | Mechanical Testing Such as Tensile of Area, Hardness Test, Chemical Analysis – Spectro Analysis, Positive Material Identification – PMI Testing, Flattening Test, Micro and MacroTest, Pitting Resistance Test, Flaring Test, Intergranular Corrosion (IGC) Test |

| Documents | Commercial Invoice, Packing List, Certificate of Origin, Fumigation Certificates, Raw Material Test Reports, Material Traceability Records, Quality Assurance Plan (QAP), Heat Treatment Charts, Test Certificates certifying NACE MR0103, NACE MR0175, Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Guarantee Letter, NABL approved Laboratory Test Reports |

Chemical Composition of ASTM A312 Duplex 2205, 1.4462, UNS S31803/S32205 Seamless or Welded Stainless Steel Pipes

| Grade | | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 2205 (S31803) | Min | – | – | – | – | – | 21 | 2.5 | 4.5 | 0.08 |

| Max | 0.03 | 2 | 1 | 0.03 | 0.02 | 23 | 3.5 | 6.5 | 0.2 |

| 2205 (S32205) | Min | – | – | – | – | – | 22 | 3 | 4.5 | 0.14 |

| Max | 0.03 | 2 | 1 | 0.03 | 0.02 | 23 | 3.5 | 6.5 | 0.2 |

Mechanical and Physical Properties of ASTM A312 Duplex 2205, 1.4462, UNS S31803/S32205 Seamless or Welded Stainless Steel Pipes

Duplex Stainless Steels have roughly twice the yield strength of their counterpart austenitic grades. This allows equipment designers to use thinner gauge material for vessel construction.

| Density | 7.8 g/cm3 |

| Melting Point | 1440 °C (2625 °F) |

| Tensile Strength | Psi – 90000 , MPa – 620 |

| Yield Strength (0.2%Offset) | Psi – 65000 , MPa – 450 |

| Elongation | 30% |

Other Grades Chemical Composition Comparison

| Grade | UNS | Composition, % in Max. |

| Designation | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | . . . | . . . |

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | 0.10-0.16 |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–15 | 2.00–3 | . . . |

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–13 | . . . | 0.10-0.16 |

| TP317L | S31700 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | . . . |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . |

Other Grades Mechanical Properties Comparison

| Grade | UNS Designation | Tensile Strength, Min. Ksi [MPa] | Yield Strength, Min. Ksi [MPa] |

| TP304 | S30400 | 75 [515] | 30 [205] |

| TP304L | S30403 | 70 [485] | 25 [170] |

| TP316 | S31600 | 75 [515] | 30 [205] |

| TP316L | S31603 | 70 [485] | 25 [170] |

| TP317L | S31703 | 70 [485] | 25 [170] |

| TP321 | S32100 | 75 [515] | 30 [205] |

| TP347 | S34700 | 75 [515] | 30 [205] |

| TP347H | S34709 | 75 [515] | 30 [205] |