Stainless Steel 304/304L Flange Manufacturers, Suppliers, Stockist – UNS S30400/S30403, 1.4307/1.4301 Flanges

Buy High Quality Stainless Steel 304/304L Flanges (ASTM A182 F304, F304L) at Factory Prices!

Low Prices for Stainless Steel 304/304L Flanges is Guaranteed!

We Will Quote for Stainless Steel 304/304L Flanges in 2 Hours with Mill Test Certificates!

| Stainless Steel 304 Flanges | Stainless Steel 304L Flanges |

| UNS S30400 Stainless Steel Flanges | UNS S30403 Stainless Steel Flanges |

| 1.4301 Stainless Steel Flanges | 1.4307 Stainless Steel Flanges |

- Metallica is engaged in manufacturing stainless steel 304/304L flanges, and executes supplies both from stock and production. Our stock consists of stainless steel 304 flanges in outside diameters ranging from 1/2” NB – 36” NB. All sizes are supplied with clean surfaces and tight dimensional tolerances to reduce the risk of leakages when connecting tubes. All our stainless steel 304/304L flanges are manufactured in accordance to major International Standards such as ASTM, ASME, EN or ISO. To ensure the high quality of our flanges, we perform 100% Ultrasonic Test, and 100% PMI Testing.

- Stainless steel 304 flanges have better resistant performances on corrosion environment and always provides with a good appearance as compared to carbon steel flanges. We are India’s leading exporter and manufacturer of stainless steel 304/304L flanges. In addition to being the lowest cost supplier of stainless steel 304/304L flanges, buttweld pipe fittings, and forged pipe fittings; we are also one of the biggest stainless steel 304/304L seamless pipe manufacturer, stockist, dealer and distributor.

- Our objective is to achieve highest volume sales, allowing us to offer maximum discount to our customers. All standard size and type in stainless steel 304/304L flanges are available Ex-stock, and we can offer immediate delivery and inspection for all our goods.

- With minimum yield strength of 170 Mpa, minimum tensile strength of 485 Mpa, and minimum Elongation of 35%, stainless steel 304L flanges are widely used for engineering and general purpose applications. In comparison, the ASTM specifications require minimum yield strength of 205 Mpa, minimum tensile strength of 515 Mpa, and minimum Elongation of 35% for stainless steel 304 flanges. Stainless steel 304/304L flanges also have good heat resistant and corrosion resistant properties.

- Stainless steel 304 (SS 304) is the most basic stainless steel known as 18-8 grade with higher chromium and low carbon content. The low carbon content restricts carbide precipitation during welding as well as minimizes its susceptibility to intergranular corrosion. Stainless steel 304L (SS304L) is an extra low-carbon variation of SS304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding. Both SS304 and SS304L have excellent resistance to a wide range of atmospheric, chemical and petrochemical, and food industry corrosions. Usually, they can be used in applications with the maximum temperature of 1650°F[900°C] exhibiting good oxidation resistance.

Manufacturer of Stainless Steel 304/304L Flanges in India

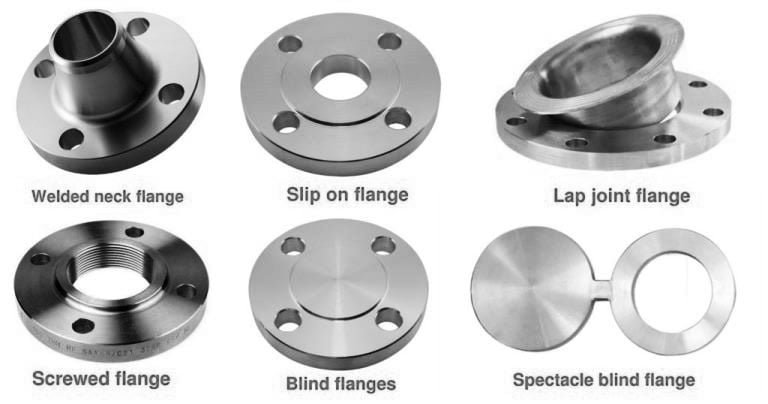

- Various Types of Stainless Steel 304/304L Flanges – Stainless Steel 304 Slip On Flanges (SORF Flanges), Stainless Steel 304 Weldneck Flanges (WN Flanges), Stainless Steel 304 Blind Flanges (BLRF Flange), Stainless Steel 304 Socket Weld Flanges, Stainless Steel 304 Orifice Flanges, Stainless Steel 304 High Hub Flanges, Stainless Steel 304/304L Square Flanges, Stainless Steel 304 Lap Joint Flanges, Stainless Steel 304/304L Loose Flanges, Stainless Steel 304 Flat Flanges/Plate Flanges, Stainless Steel 304 Ring Type Joint Flanges (RTJ Flanges), Stainless Steel 304/304L Threaded Flanges, Stainless Steel 304 Expander Flanges, Stainless Steel 304 Spectacle Flange.

Stock & Production Range for Stainless Steel 304/304L Flanges (UNS S30400/1.4301, UNS S30403/1.4307)

| Product | Stainless Steel 304/304L Flanges |

| Equivalents | AISI 304, AISI 304L, UNS S30400, UNS S30403, WNR.1.4301/1.4307 |

| Specifications | ASTM A182, ASTM A240 |

| Size | 1/2″ NB to 60″ |

| Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Raw Materials | Round Bars, Billets |

| Certification | EN 10204 3.1 |

| Prices | info@metallicametals.com | +918928722715 |

- We Specialize in manufacturing custom size stainless steel 304 flanges.

Full Range of Stainless Steel 304/304L Products

| Stainless Steel 304/304L Pipes | Stainless Steel 304/304L Seamless Pipes |

| Stainless Steel 304/304L Welded Pipes | Stainless Steel 304/304L Square/Rectangular Pipes |

| Stainless Steel 304/304L Flanges | Stainless Steel 304/304L Buttweld Fittings |

| Stainless Steel 304/304L Forged Fittings | SS 304/304L Socket Weld Pipe Fittings |

| Stainless Steel 304/304L Threaded Fittings | Stainless Steel 304/304L Fasteners |

| Stainless Steel 304/304L Nuts & Bolts | Stainless Steel 304/304L U Bends & Tubes |

| Stainless Steel 304/304L Valves | Stainless Steel 304/304L Tubes |

| Stainless Steel 304/304L Furnace Tubes | Stainless Steel 304/304L Seamless Tubing |

| SS 304/304L Heat Exchanger Tubes | Stainless Steel 304/304L Large Dia. Pipes |

| Stainless Steel 304/304L Boiler Tubes | SS 304/304L High Pressure Pipes |

| Stainless Steel 304/304L Forgings | SS 304/304L High Temperature Pipes |

| Stainless Steel 304/304L Instrumentation Tubes | Stainless Steel 304/304L Instrumentation Tube Fittings |

| Stainless Steel 304/304L High Pressure Pipe Fittings | Stainless Steel 304/304L Tube Fittings |

| Stainless Steel 304/304L Plate Cut Circles | Stainless Steel 304/304L Forged Rings |

| Stainless Steel 304/304L Blocks for Machining | Stainless Steel 304/304L Round Bar |

| Stainless Steel 304/304L Flat Bars | Stainless Steel 304/304L Angle Bars |

| Stainless Steel 304/304L Rods | Stainless Steel 304/304L Threaded Rods |

| Stainless Steel 304/304L Sheet/Plates | Stainless Steel 304/304L Coils/Strips |

Types of Flanges –What are the Various Types of Flanges?

A flange can be characterized and classified in various ways such as:

-Types of Connection

-Flange facing Types

-Pressure Temperature Ratings

-Material Types

The standard type of steel flanges mostly used are:

- Stainless Steel 304/304L Welding Neck Flange: This type of flange has a neck that is welded to the end of pipes. It is used for high pressure applications to reduce the concentration of stress. Generally machined from a forging, these flanges are typically butt welded to a pipe. Weld-neck flanges have a higher life expectancy than slip-on flanges under duress.

- Stainless Steel 304/304L Slip On Flange: Slip-On flanges or SO flanges are commonly lower in price than weld-neck flanges, and to this effect are a popular choice for many users. These pipe flanges slip over the pipe. They’re manufactured with an inside diameter that is slightly bigger than the pipe’s outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

- Stainless Steel 304/304L Socket Weld Flange: A socket weld flange has a female socket in which pipe is fitted. Fillet welding is done from outside on the pipe. The socket welding flange is similar to a slip-on flange except it has a bore and a counter bore dimension. The counter bore is slightly larger than the O.D. of the matching pipe, allowing the pipe to be inserted into the flange similar to a slip-on flange. The diameter of the smaller bore is the same as the I.D. of the matching pipe A restriction is built into the bottom of the bore which sets as a shoulder for the pipe to rest on. When using a socket weld flange, the inner diameter needs to be the same as the inner diameter of the pipe. The socket flange is only suitable for pipes with a nominal diameter of 150 or less.

- Stainless Steel 304/304L Lap Joint Flange: Lap Joint Flanges (LJ Flanges) are used on piping fitted with lapped pipe or with lap joint stub ends the combined initial cost of the two items being approximately one-third higher than that of comparable welding neck flanges. Lap joint flange is having two components, a stub end, and a loose backing flange. Stub end is butt welded to the pipe and Backing flange freely move over the pipe. The backing flange can be of different material than stub material and normally of the carbon steel to save the cost. Lap flange is used where frequent dismantling is required, and space is constrained. The lap joint flange is practically identical to a slip-on flange except it has a radius at the intersection of the bore and flange face. The lap joint flange is practically identical to a slip-on flange except it has a radius at the intersection of the bore and flange face. This radius is necessary to have the flange accommodate a lap joint stub end. Normally, a lap joint flange and a lap joint stub end are mated together is an assembly system.

- Stainless Steel 304/304L Threaded Flange: Threaded Flanges are also known as screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. Threaded flanges are widely demanded as pipe flanges i.e called as threaded pipe flanges used in different industrial applications. This type of joint connection is speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water. Threaded (Screwed) flange is similar to the Slip-On flange, but the bore is threaded. Its chief merit is that it can be assembled without welding, explaining its use in low pressure services at ordinary atmospheric temperatures, and in highly explosive areas where welding create a hazard. Threaded flanges are not suitable for use where the temperature of the pipe changes sharply or the temperature is higher than 25°C and lower than -40°C.

- Stainless Steel 304/304L Blind Flange: A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened. The blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made. Blind Flanges are commonly used in petrochemical, pipe engineering, public services & water works. Blind pipe flanges are often used for high pressure applications.

In addition to the most used standard flanges, there are still a number of special steel flanges such as:

- Stainless Steel 304/304L Orifice Flange: Orifice flanges are used instead of the standard pipe flanges when orifice plate or flow nozzle is used. In other words, orifice flanges are used with orifice meters. The basic purpose for this is to measuring the flow rate of either gases or liquids in the respective pipeline.

- Stainless Steel 304/304L Long Welding Neck Flange: Long weld neck flange(LWN flange) is also call integral flange, it means a welding neck flange has a very long neck. Commonly, the welding neck flange has a tapered neck and a bevel end which is going to butt welding with the matching pipe. But the long weld neck flange, has a straight short pipe as the neck of a long weld neck flange.

- Stainless Steel 304/304L Weldoflange & Nipoflange: The Weldoflange and Nipoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. The 2 components are manufactured in one piece, and not welded. These flanges are primarily in Branch connections. Furthermore, they have an expanded range of special flanges, fittings and branch connections.

- Stainless Steel 304/304L Expander & Reducing Flange: Expanding and reducing flanges are used to increase or decrease the bore size of a pipeline. Expander and reducer flanges are a good alternative to butt weld reducers when the required pipeline bore reduction or increase is small (one or two sizes). For larger size changes, the use of buttweld fittings is recommended.

Selection of the Type of Flange Connection with Pipes

- Steel pipes can be connected to flanges by welding the pipe with the flange (welded connection, made with weld neck, socket weld, slip on and lap joint flanges) or by screwing the flange onto the pipe (threaded connection, made using threaded flanges).

- Welded connections are used for pipelines and piping systems featuring high pressures and temperatures, and diameters above 2 inches. Threaded connections are used for small diameter piping systems that are not subject to mechanical forces as expansion, vibration, contraction, oscillation (conditions that would crack the threaded joints). Let’s take a close look at the welded connections types.

Weld Neck Connection (Weld Neck Flanges)

- Weld-neck flanges have a tapered hub with a butt weld end that can be welded to a butt weld pipe. The quality of the welded joint should be examined by dye penetrant test (DP) or using radiography and/or ultrasounds (UT).

- The welded connection between a weld neck flange and a pipe features a good fatigue and mechanical stress performance.

Socket Weld Connection (Socket Weld Flanges)

- Socket weld flanges are most preferred for use in high pressure piping systems generally below 2 inches (DN 50).

- The pipe is fillet-welded to the hub of the socket weld flange. The quality of weld is of utmost importance in this kind of a flange connection, and appropriate inspection should be done before moving the system into operation.

Slip-On Connection (Slip On Flanges)

- Slip-on flanges are generally preferred to weld-neck flanges due to their lower cost and installation speed (and ease).

- The disadvantage of slip on flanges over weld neck flanges is that their strength is about 1/3 lower.

- Due to lower strength slip on flanges are typically used for low-pressure, non-critical services.

- The pipe is welded to both the hub and the bore of the flange. Slip-on flanges are used, generally, for pipe sizes greater than NPS 2¹⁄₂ (DN 65).

Lap Joint Connection (Lap Joint Flanges and Stub Ends)

- This type of connection is sometimes used for pipelines in high-cost materials (as stainless steel and nickel alloys) as it helps to reduce the overall cost of the required flanged connections.

- A lap joint connection is made by the combination of a stub end (which is the part welded to the pipe) and a backing flange, or lapped flange.

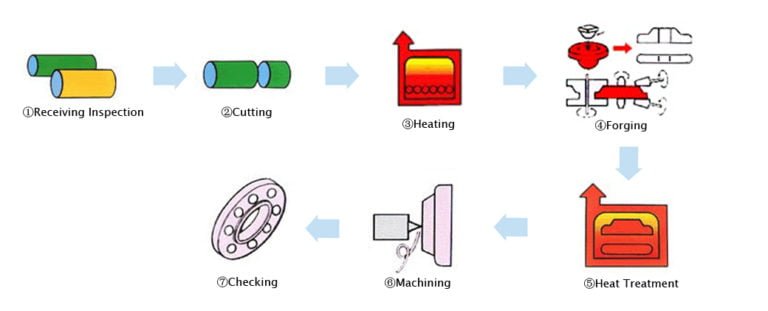

Manufacturing Process for Stainless Steel 304/304L Flanges

A flange is produced either by forging, casting, cutting, or rolling. We produce flanges mainly by forging, cutting, and rolling process.

Forged Stainless Steel 304/304L Flange Manufacturing Process

The forging process is usually composed of the following processes, namely, the selection of quality steel billet, heating, forming and cooling.

Flange Manufacturing Process

- Inspection of Raw Material – The key raw material for producing flanges is steel billets or hot rolled bars. All raw materials purchased are supplied with test reports as per EN 10204 3.1, with full traceability. It is the first compulsory step in the production process for flanges to guarantee good quality. The raw materials are re-tested inhouse for assurance on chemical composition, mechanical capacity and metallographic analysis.

- Cutting Raw Material – Correctly and strictly controlling cutting size and proportion can ensure adequate control on the cost.

- Heating – It is a very important step for flange quality. It is the necessary to record the heating temperature in details to avoid overheating. Overheating will destroy the structure of the metal and mechanical properties pf the raw materials.

- Forging – Forging process is divided into free forging and die forging. The forging time and strength of flange is different for different pressure class.

- Heat Treatment – The purpose of heat treatment is to eliminate the stress inside of flange so that the density is more evenly. Carefully recording the temperature of heat treatment and cooling time are the keys.

- Forging Blank Inspection – After the heat treatment process has been carried out, a sample of the lot is chosen to test the chemical composition and mechanical property again to ensure all items are qualified.

- Machining of Forged Blanks – In the machining process, the inspection is carried out along with the processing, so that to guarantee each part of flange is qualified. Machining is undertaken on CNC and/or lathe machines.

- Finishing Goods Inspection – Finished products will be checked 100% before delivery to ensure the goods are perfect as per ASME, EN or customer standards.

- Documentation – The whole production process and quality checks at different levels is documented as per standard operation procedure under ISO compliance. It is the guarantee for good quality.

- Test Certificate: Since we are a ISO and PED certified manufacturer, we can issue test certificate as per EN 10204 3.1 for all the goods at the time of delivery and inspection.

- Packing: All forgings and flanges are packed in wooden crates or box or pallets to ensure secure movement of goods.

Stainless Steel 304/304L Plate Cut Flanges Manufacturing Process

- The process here is relatively simple, with the key raw material being hot rolled plates. This process is mainly used for producing slip on plate flanges and blind flanges for lower thickness. All plates procured are accompanied with tested certificates as per EN 10204 3.1.

- Circles are cut from plates.

- Heat treatment is not involved in this process of manufacturing flanges.

- Drilling and machining is done on circles to achieve the desired dimensions.

- Goods are visually inspected and marked with relevant standards.

Testing & Inspection of Stainless Steel 304/304L Flanges

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Stainless Steel 304/304L Flanges

Prices for stainless steel 304/304L flanges are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of stainless steel 304/304L flanges, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our pricelist for various steel products on our blog.

Documents Provided at the time of Domestic Sales or Export of Stainless Steel 304/304L Flanges

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Gurantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Basis for Stainless Steel 304/304L Flanges

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Stainless Steel 304/304L Flanges

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not availabe in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Stainless Steel 304/304L Flanges

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

About 304/304L Stainless Steels

What is 304/304L Stainless Steel?

- Grade 304 stainless steel has a minimum of 18% chromium and 8% nickel, combined with a maximum of 0.08% carbon. The remainder of its composition is made up of carbon, manganese, silicon and very small amounts of phosphorous and sulfur. It is defined as a Chromium-Nickel austenitic alloy. Grade 304 is the standard “18/8” stainless that you will probably see in your pans and cookery tools. Additionally, the metal is pliable under both hot and cold working, though it responds better to cold working; it will only work harden under cold working. Extended exposure to temperatures between 800–1500°F can lead to embrittlement and should be carefully monitored.

- Grade 304L is the low carbon version of 304, and although the two types share many of the same properties, it is the differences in carbon content that differentiates them. It does not require post-weld annealing to effectively maximize corrosion resistance and so is extensively used in heavy gauge components (over about 6mm). Grade 304H with its higher carbon content finds application at elevated temperatures. Additionally, it also possesses a higher work hardening rate. 304L exhibits excellent resistance in a variety of atmospheres and temperatures, along with the corrosion and oxidation that occurs over time. However, like many stainless steels, it is susceptible to warm chlorine environments and can potential pit and crack.

- Stainless Steels 304 and 304L can be commonly found dually certified. This utilized the widely applicable properties of both metals and meets the individual specifications for each.Grade 304/304L is the most widely used commercial grade of stainless steel supplied into numerous industry sectors. It has excellent corrosion resistance in ordinary atmospheric conditions, it is easily machined and is also easy to weld. Whilst performing well when exposed to relatively high temperatures, this grade of stainless steel like most austenitic stainless grades, also maintains its strength and toughness at sub-zero temperatures, making this an excellent choice for various applications and industries such as food & drink processing, petrochemical and construction.

Product Forms and Standards of 304/304L Stainless Steel

| Product Forms | Material Standards |

| Plates, Sheets & Strips | ASTM A240, A666 |

| Billets, Bars & Rods | ASTM A276, A314, A479 |

| Forgings(Flanges & Fittings) | ASTM A182, A473. |

| Wires | ASTM A313, A368, A478, A492, A493, A580. |

| Seamless and Welded Pipes | ASTM A312, A358, A813, A814. |

| Wrought Pipe Fittings | ASTM A403 |

| Castings(Cast Fittings & Valve Parts) | ASTM A351, A743, A744 |

Applications of Stainless Steel 304 Materials

SS 304 is a stainless steel with applications ranging from the manufacturing of chemical equipment, kitchen and cooking utensils and equipment, to surgical tools and textile dyeing equipment. SS 304L is used for applications where a low carbon count is required, such as in heavy gauge components. It is often applied in areas of higher temperatures than Type 304 can endure, and its low carbon allow it to be resistant against carbon precipitation. It is used for a wide variety of home and commercial applications, this is one of the most familiar and most frequently used alloys in the stainless steel family. Typical applications include tanks and containers for a large variety of liquids and solids:

- Food industry

- Domestic tools industry

- Architectural panelling, railings & trim

- Chemical containers, including for transport

- Heat Exchangers

- Woven or welded screens for mining, quarrying & water filtration

- Dyeing industry

- In the marine environment, because of it slightly higher strength and wear resistance than type 316 it is also used for nuts, bolts, screws, and other fasteners.

Chemical & Mechanical Properties of Stainless Steel 304/304L

| Material | UNS | EN | Chemical Component % | ||||||

| C | Mn | P | S | Si | Cr | Ni | |||

| 304 | S30400 | 1.4301 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 18.00-20.00 | 8.00-10.00 |

| 304L | S30403 | 1.4307 | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 18.00-20.00 | 8.00-10.00 |

| Material | UNS | EN | Tensile Strength | Yield Strength | Elongation | Heat Treatment |

| (Mpa) min | (Mpa) min | (%) | ℃ | |||

| 304 | S30400 | 1.4301 | 515 | 205 | 35 | 1040 |

| 304L | S30403 | 1.4307 | 485 | 170 | 35 | 1040 |

Properties and Processing Characteristics of Stainless Steel 304/304L

- The metal is characterized by its corrosion resistance, especially in cases of oxidation and salt water. Otherwise referred to as Grade 304 or Type 304, it is the most commonly utilized grade of stainless steel, being extremely versatile in application, form, and finishes. This makeup ensures that SS 304 has a well-balanced level of performance in terms of weldability, corrosion resistance and anti-oxidation properties.

- Alloy 304/304L has excellent strength and toughness at cryogenic temperatures. Alloy 304/304L is non-magnetic in the annealed condition, but can become slightly magnetic as a result of cold working or welding. It can be easily welded and processed by standard shop fabrication practices.

- Good oxidation resistance in intermittent service to 870°C and in continuous service to 925°C. Continuous use of 304 in the 425- 860°C range is not recommended if subsequent aqueous corrosion resistance is important. Grade 304L is resistant to carbide precipitation and can be heated into this

temperature range. - Heat treatment – Solution Treatment (Annealing) to 1010-1120°C and cool rapidly. These grades cannot be hardened by thermal treatment.

Equivalents of Stainless Steel 304/304L

| STANDARD | SS 304 | SS 304L | SS 304H |

| UNS | S30400 | S30403 | S30409 |

| WERKSTOFF NR. | 1.4301 | 1.4306 | 1.4948 |

Physical Properties of Stainless Steel 304/304L

- Density: 8.03g/cm3

- Electrical resistivity: 72 microhm-cm (20C)

- Specific Heat: 500 J/kg °K (0-100°C)

- Thermal conductivity: 16.3 W/m-k (100°C)

- Modulus of Elasticity (MPa): 193 x 103 in tension

- Melting Range: 2550-2650°F (1399-1454°C)

Corrosion Resistance of 304/304L Stainless Steel

- Alloy 304/304L has good resistance to atmospheric corrosion, foods and beverages and to many organic and inorganic chemicals in moderately oxidizing to moderately reducing environments. The high chromium content of the alloy provides resistance to oxidizing solutions such as nitric acid up to 55% weight and up to 176°F (80°C). Alloy 304/304L also resists moderately aggressive organic acids such as acetic. The nickel present in the alloy provides resistance to moderately reducing solutions such as pure phosphoric acid, whatever the concentration, in cold solutions and up to 10% diluted hot solutions. The alloy can also operate successfully in caustic solutions free of chlorides or fluorides at moderate temperatures.

- Alloy 304/304L does not perform well in more highly reducing environments such as those containing chlorides and sulfuric acid. Alloy 304/304L performs well in fresh water service with low levels of chlorides (less than 100ppm). At higher chloride levels the grade is susceptible to crevice corrosion and pitting. For successful performance under these more severe conditions, higher molybdenum content is need such as 316/316L. Alloy 304/304L is not recommended for service in marine environments.

- In most instances, the corrosion resistance of Alloys 304, 304L and 304H will be roughly equal in most corrosive environments. However, in environments that are sufficiently corrosive to cause intergranular corrosion of welds and heat-affected zones Alloy 304L should be used because of its low carbon content.

Fabrication Data of Stainless Steel 304/304L

Alloy 304/304L can be easily welded and processed by standard shop fabrication practices.

- Hot Forming:- Working temperatures of 1652–2102°F (750–1150°C) are recommended for most hot working processes. For maximum corrosion resistance, the material should be annealed at 1900°F (1038°C) minimum and water quenched or rapidly cooled by other means after hot working.

- Cold Forming:- The alloy is quite ductile and forms easily. Cold working operations will increase the strength and hardness of the alloy and might leave it slightly magnetic.

- Welding:- Alloy 304/304L can be readily welded by most standard processes. A post weld heat treatment is not necessary.

- Machining:- Alloy 304/304L is subject to work hardening during deformation and is subject to chip breaking. The best machining results are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling and powerful rigid equipment.