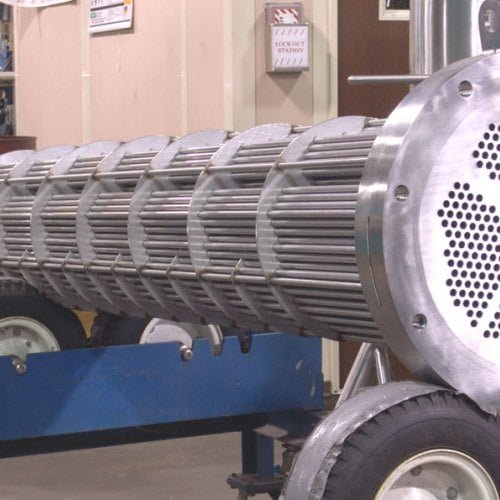

One of the largest manufacturer and supplier of stainless steel 347/347H seamless U bend tubes. All our tubes are 100% quality tested, which include chemical testing, mechanical testing as well as hydro testing. All SS 347/347H U bend Tubes are heat treated, solution annealed, and pass hydrostatic test and eddy current test.

Each SS 347/347H U bend tube of our range is quality checked by our quality team on every stage of production to deliver the clients defect free best quality products.

- OD 9.5mm – 38.1mm

- WT up to 6.35mm

- Bending radii 1.25 x OD up to 1700mm

- Bends can be supplied in accordance with TEMA R / ASTM SA/A556

- Leg length up to 15000mm

- Heat treatment where required by electric furnance or direct resistance

- All tubes are stress relieved after U-bending

- Hydrotesting up to 10,000 psi

- Large Scale Enterprise – Metallica is biggest stock holding, manufacturing and processing company of SS 347/347H U bend tubes in India. Our large volume production, sales and purchase enables us to offer our products at the most competitive prices in the industry.

- Testing of Stainless Steel 347/347H U Bend Tubes – All SS 347/347H U bend tubes are subjected to hydrostatic test, eddy current test, chemical and mechanical tests during the various stages of production.

- Marking & Packing of Stainless Steel 347/347H U Bend Tubes – Marking on all pipes is as per the predefined rules in the specification.

- Test Certificates & Inspection of SS 347/347H U Bend Tubes – All our pipes are supplied with Mill test Reports, as per EN 10204 3.1. We can also allow third party inspection of all our products before delivery.

- We have own QC team to control the quality to meet particular standard strictly

- Short Lead Times – We can offer AISI 347/347H, 1.4550/1.4961, UNS S34700/S34709 U bend tubes and pipes with shortest delivery time.

- We can produce either standard or non-standard of the stainless steel 347/347H U bend pipes.

What is 347/347H Stainless Steel?

Type 347 is a niobium stabilized chromium nickel austenitic stainless steel with corrosion resistance similar to 304/304L. 347 stainless steel is a columbium/tantalum stabilized austenitic chromium-nickel stainless steel. This grade is typically used in the 800-1500˚F temperature range where it is stabilized against chromium carbide precipitation by the addition of niobium, which results in the precipitation of niobium carbides. Type 347 has excellent intergranular corrosion resistance after exposure to this temperature range, and this grade resists oxidation up to 1500˚F and has higher creep and stress rupture properties than 304/304L. It also possesses good low temperature toughness and is non-magnetic in the annealed condition. This material is stabilized against chromium carbide formation by the addition of columbium and tantalum. Since these elements have a stronger affinity for carbon than chromium, columbium-tantalum carbides precipitate within the grains instead of forming at the grain boundaries. 347 is non-magnetic.

Stainless Steel 347H is another stainless steel in a class of metals labeled of precipitation-hardened steels. It possesses many of the same properties and characteristics of stainless steel 347. In addition to its higher carbon content, the alloy is stabilized with an addition of columbium, or sometimes tantalum. Both these properties allow 347H to be exposed to higher temperatures than both 347 and the 304 stainless steel grades can withstand. Because of its elevated resistance to corrosion, 347H is often applied in high stress, high corrosion environments where exposure tends to be severe. High temperature manufacturing, steam pipes, boiler tubes, chemical processes and steam servicing all benefit from 347H’s resilience. This resilience in turn is due to the potentially elevated levels of chromium in 347H’s composition. The metal can contain anywhere from 4-30%.

The metal displays high workability under most common welding techniques. It can be treated with heat, however, it will not respond. Only cold working is sufficient to increase 347H’s toughness and strength.

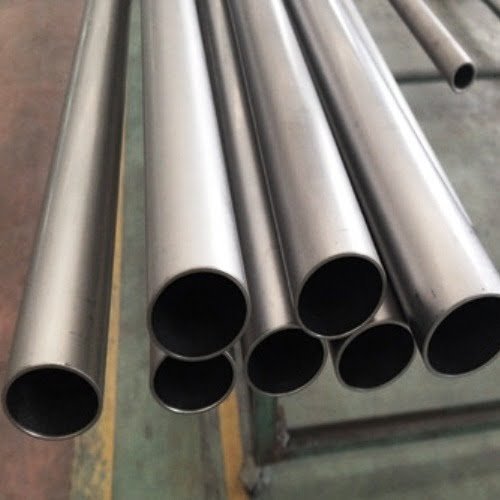

Manufacturing Range for Stainless Steel 347/347H, 1.4550/1.4961, UNS S34700/S34709 Seamless or Welded Stainless Steel Pipes

| Product | ASTM A312 TP347/TP347H, 1.4550/1.4961, UNS S34700/S34709 Stainless Steel Pipes |

| Specification | ASTM A312 / A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes |

| Type | Seamless & Welded |

| Size Range | Size: 1/8” to 24” (10.3mm to 610mm) – Seamless |

| Size:1/8” to 36” (10.3mm to 914mm) – Welded |

| 1/8” OD to 6” OD |

| Thickness | 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXH |

| Wall Thickness: 1mm to 60mm |

| Length | 6 Meter, Custom Lengths |

| Other Grades | TP304, TP304L, TP304LN, TP316, TP316L, TP316LN, TP317, TP317/317L, TP321, TP347, TP310S |

| Test Certificates | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| ASTM Reference Standards | - A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels.

- A370 Test Methods and Definitions for Mechanical Testing of Steel Products.

- A480 A480M Specification for general requirements for Flat-rolled stainless and Heat-Resisting steel plate, sheet, and strip.

- A632 Specification for Seamless and welded austenitic stainless-steel tubing (small-diameter) for general service.

- A1016 A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless-Steel Tubes.

- E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

|

| Testing | Mechanical Testing Such as Tensile of Area, Hardness Test, Chemical Analysis – Spectro Analysis, Positive Material Identification – PMI Testing, Flattening Test, Micro and MacroTest, Pitting Resistance Test, Flaring Test, Intergranular Corrosion (IGC) Test |

| Documents | Commercial Invoice, Packing List, Certificate of Origin, Fumigation Certificates, Raw Material Test Reports, Material Traceability Records, Quality Assurance Plan (QAP), Heat Treatment Charts, Test Certificates certifying NACE MR0103, NACE MR0175, Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Guarantee Letter, NABL approved Laboratory Test Reports |

Chemical Composition of ASTM A312 TP347/TP347H, 1.4550/1.4961, UNS S34700/S34709 Seamless or Welded Stainless Steel Pipes

| ELEMENT | 347 | 347H |

| NI | 17.0 – 20.0 | 17.0 – 19.0 |

| C | 0.08 max | 0.04 – 0.10 |

| MN | 2.0 max | 2.0 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| SI | 1.0 max | 1.0 max |

| CR | 17.0 – 19.0 | 17.0 – 19.0 |

| NB | 10xC – 1.10 | 8xC – 1.10 |

Physical Properties ASTM A312 TP347/TP347H, 1.4550/1.4961, UNS S34700/S34709 Seamless or Welded Stainless Steel Pipes

| Units | Temperature in °C |

| Density | 7.97 g/cm³ |

| Specific Heat | 0.12 Kcal/kg.C |

| Melting Range | 1398 – 1446 °C |

| Modulus of Elasticity | 193 KN/mm² |

| Electrical Resistivity | 72 µΩ.cm |

| Coefficient of Expansion | 16.0 µm/m °C |

| Thermal Conductivity | 16.3 W/m -°K |

| Annealed | 1040 – 1100 (°C) / 1900 – 2000 (°F) |

| Quenched | Rapid Air/Water |

Mechanical Properties ASTM A312 TP347/TP347H, 1.4550/1.4961, UNS S34700/S34709 Seamless or Welded Stainless Steel Pipes

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 75 | 30 | 40 |

Other Grades Chemical Composition Comparision

| Grade | UNS | Composition, % in Max. |

| Designation | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | . . . | . . . |

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | 0.10-0.16 |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–15 | 2.00–3 | . . . |

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–13 | . . . | 0.10-0.16 |

| TP317L | S31700 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | . . . |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . |

Other Grades Mechanical Properties Comparision

| Grade | UNS Designation | Tensile Strength, Min. Ksi [MPa] | Yield Strength, Min. Ksi [MPa] |

| TP304 | S30400 | 75 [515] | 30 [205] |

| TP304L | S30403 | 70 [485] | 25 [170] |

| TP316 | S31600 | 75 [515] | 30 [205] |

| TP316L | S31603 | 70 [485] | 25 [170] |

| TP317L | S31703 | 70 [485] | 25 [170] |

| TP321 | S32100 | 75 [515] | 30 [205] |

| TP347 | S34700 | 75 [515] | 30 [205] |

| TP347H | S34709 | 75 [515] | 30 [205] |