Top Molybdenum Manufacturers, Suppliers, Stockist – Moly Alloy Pipe, Mo-La Tube, TZM Tube, TZM0092 Alloy, Mo Wire, Mo Sheet, Mo Plate Dealers – ASTM B387/B386

✅ Why Choose Metallica for Molybdenum Products

-

All molybdenum products are offered with high quality standards at competitive prices.

-

We are a leading manufacturer and distributor of molybdenum products in India.

-

Customers can confidently wholesale quality products at stock prices directly from our factory.

-

Metallica is one of the largest suppliers and stockists of molybdenum products, serving over 250 customers in India and abroad.

-

We are bulk producers, suppliers, and exporters from facilities in India, USA, Japan, Korea, and Europe.

-

Our global sourcing network allows us to offer the best price and quality — delivered just-in-time.

-

We focus on volume sales and global customer expansion, allowing us to operate on low margins.

-

Strong trader network across India and the Middle East.

-

Trusted by EPC contractors, industrial companies, and end-users across diverse sectors.

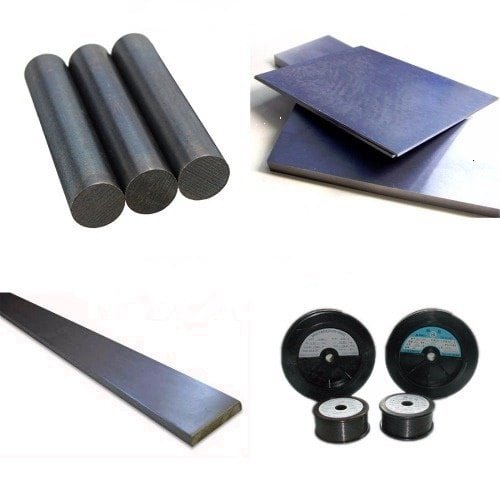

📦 Wide Range of Molybdenum Products Available – We stock all major forms, including:

-

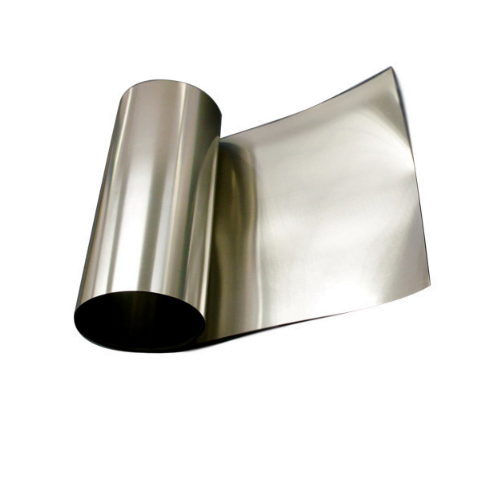

Sheets, Plates, Foils, Strips

-

Pipes, Tubes (Seamless & Welded)

-

Bars, Rods, Round Bars, Rectangular Bars

-

Rings, Targets, Washers, Sleeves, Sheaths

-

Screws, Wires, Alloys (Molybdenum-Tungsten, Molybdenum-Copper)

-

Powder, Pellets, Granules, Ingots, Oxide & Compound Forms

-

(Custom shapes and sizes available on request.)

🔧 Expertise in Seamless & Welded Tubing

-

We specialize in seamless molybdenum pipes and tubes in round, square, rectangular, and oval shapes.

-

Size range:

-

Diameter: 0.02″ to 6.0″

-

Wall Thickness: 0.003″ to 0.500″

-

-

Welded tubes (made from molybdenum sheets) are polished post-welding for superior surface finish.

-

Seamless tubes are ideal for thicker wall sections, while welded tubes suit thinner wall requirements.

🔩 Advanced Molybdenum Alloys Available

-

-

We also supply Molybdenum Alloy Tubes, including:

-

TZM Tubes

-

Mo-La (La₂O₃ Doped Moly) Tubes

-

-

These alloys offer:

-

High creep resistance

-

Superior recrystallization temperature

-

Excellent thermal stability

-

-

Molybdenum Manufacturers, Suppliers

Molybdenum Dealers, Stockist

Production and Stock Range of Molybdenum

| Material: | Pure Molybdenum, Molybdenum Alloy |

| Size: | OD: 30~500mm, WT: 0.3~30mm, Length: ≤4000mm |

| Purity: | ≥99.95%, TZM, TZC, MoLa, etc |

| Standard: | ASTM B386, ASTM B387 |

| Status: | Machining, Sintering, Welding, Stretching |

| Density: | 9.8~10.2g/cm3 |

| Technology: | Powder metallurgy |

Grade Specification of Molybdenum

- Molybdenum 360—Unalloyed vacuum arc-cast molybdenum.

- Molybdenum 361—Unalloyed powder metallurgy molybdenum.

- Molybdenum Alloy 363—Vacuum arc-cast molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

- Molybdenum Alloy 364—Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

- Molybdenum 365—Unalloyed vacuum arc-cast molybdenum, low carbon.

- Molybdenum Alloy 366—Vacuum arc-cast molybdenum-30 % tungsten alloy.

Chemical Properties of Molybdenum

| Molybdenum content | Other single element content | Total content of other elements |

| ≥99.95% | ≤0.01% | ≤0.05% |

| Molybdenum alloy according to customer’s requirements | ||

Mechanical, Physical and Thermal Properties of Molybdenum

| Molecular Weight | 95.94 |

| Appearance | Silvery |

| Melting Point | 2623 °C |

| Boiling Point | 4639 °C |

| Density | 10280 kg/m3 |

| Solubility in H2O | N/A |

| Electrical Resistivity | 5.2 microhm-cm @ 0 °C |

| Electronegativity | 1.9 Paulings |

| Heat of Fusion | 6.6 Cal/gm mole |

| Heat of Vaporization | 128 K-Cal/gm atom at 4612 °C |

| Poisson’s Ratio | 0.31 |

| Specific Heat | 0.0599 Cal/g/K @ 25 °C |

| Tensile Strength | N/A |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |

| Thermal Expansion | (25 °C) 4.8 µm·m-1·K-1 |

| Vickers Hardness | 1530 MPa |

| Young’s Modulus | 329 GPa |

What is Molybdenum?

Molybdenum is gray-metallic and has the third-highest melting point of any element next to tungsten and tantalum. It is found in various oxidation states in minerals but does not occur naturally as a free metal. Molybdenum allows readily to form hard and stable carbides. For this reason, Molybdenum is frequently used for making steel alloys, high strength alloys, and superalloys. Molybdenum compounds usually have a low solubility in water. Industrially, they are used in high-pressure and high-temperature applications such as pigments and catalysts. Molybdenum is the most commonly used of all refractory metals, in part because it is the least expensive refractory metal.

Like tungsten, molybdenum is used in the medical field. However, because molybdenum is less dense than tungsten, it is not used as often in radiation shielding applications. But its higher thermal conductivity, lower thermal expansion coefficient and lower overall density make it an ideal material for use in rotating x-ray anodes and CT imaging systems. Molybdenum is better suited to diagnostic imaging than shielding applications, but this refractory metal is just as indispensible to the medical field and its emerging technologies.

Size Reference of Molybdenum Products

- Form Specifications (inches)

- Plate 0.04-1.57 Thick x 3.15-18.90 Wide x Length

- Sheet 0.004 (min) Thick x 1.57-21.65 Wide x 1.57-21.65 Long

- Wire 0.014 (min) Diameter x Length

- Rod 0.012 – 5.90 Diameter x Length

- Strip 0.001 (min) Thick x Width x Coiled

- Tube Custom Sizes Available

Manufacturing Process of Molybdenum

Molybdenum tube is provided from forged rods and sintering directly. Mo tube with OD smaller than 60mm are mostly machined and gun drilled from forged rod, tube with larger diameter are sintered per size directly. The process methods of tubes and crucibles are always for saving cost and according to customer’s requirement.

Properties of Molybdenum

- Low co-efficient of thermal expansion (5.1×10-6 m/m/°C) which is about half that of most steels

- Good thermal conductivity

- Good electrical conductivity

- Good stiffness, greater then that of steel (Young’s Modulus 317MPa)

- High melting point (2615°C)

- Good hot strength

- Good strength and ductility at room temperature

- High density (10.2 g/cm3)

- Its ability to withstand high temperatures and maintain strength under these conditions are responsible for the fact that molybdenum finds most of its application at elevated temperatures. In fact, it can work at temperatures above 1100°C (in non-oxidising conditions), which is higher than steels and nickel-based superalloys.

- When exposed to temperatures in excess of 760°C in air rapid oxidation can result. Under these conditions, the oxide layer sublimes and the base metal is attacked. Thus, molybdenum performs best in inert of vacuum environments.

Applications of Molybdenum

- Molybdenum tube (pipe) can be used at service temperature up to 1,800 degrees.

- Used in components of electron tube, heaters of high-temperature furnaces, thermocouple retainers.

- Defense

- High Purity Materials

- Metals

- Nuclear Energy

- Refractory Metals & Alloys

- Research and Laboratory

- Space

- Solar Industry

Types of Molybdenum Products

| Molybdenum Hollow Pipe | Molybdenum Heater for High Temperature |

| Molybdenum Seamless Pipe | Molybdenum Heat Exchanger Tube |

| Molybdenum Bush Hex Pipe | Potassium-doped Molybdenum Wire |

| Molybdenum Round Pipe | Molybdenum Welded Pipe |

| Molybdenum Alloy Round Pipe | Molybdenum Rotating target |

| Molybdenum Aero engine tube | Molybdenum Custom Pipe |

| Molybdenum Alloy Custom Pipe | Molybdenum Thick Wall Pipe |

| Molybdenum Elliptical and Oval Tube | Molybdenum Thin Wall Pipe |

| Molybdenum Pipe Fittings | Molybdenum Forging |

| Molybdenum Strips | Molybdenum Fasteners |

| Molybdenum Flex pipe | Molybdenum Plates, Sheets and Bars |

| Molybdenum Alloy Polished Pipe | UNS Molybdenum lined pipe |

| Molybdenum Exhaust Pipe | Molybdenum Micro Tube |

| Molybdenum Bar/Billet | Molybdenum Wire/Welding Wire |

| Molybdenum Boiler Tube | Molybdenum Coil Tubing |

| Molybdenum Capillary Tube | Molybdenum U Shaped Tube |

| Molybdenum Rods | Precision Molybdenum Tubing |

| Molybdenum Suppliers | Molybdenum Pipe Manufacturers |

| Molybdenum Ingots | Molybdenum Foil |

| Molybdenum Metals | Molybdenum Crucibles |

| ML1418 Molybdenum Lanthanum Wires (Mo-La wires) | MU1417 Molybdenum Strip (Mo strip) |

| MU0079 Molybdenum Plate (Mo Plate) | TSW0081 Molybdenum Spraying Wire (Moly Spraying Wire) |

| MU0080 Molybdenum Wire (Mo Wire) | MU1420 Molybdenum Foil (Mo Foils) MU0078 |

| Chrome Moly Tubes | MU0078 Molybdenum Sheet (Mo Sheet) |

Testing & Inspection of Molybdenum Products

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Molybdenum Materials

Pricing for Molybdenum-based materials is closely linked to the cost of raw materials like iron ore, metal scrap, chromium, nickel, and other alloying elements. The production of heat-resistant stainless steels and nickel alloys tends to be more expensive due to their high nickel and chromium content.

On the other hand, mild steel remains the most cost-effective option, followed by carbon steel, 400-series stainless steels, aluminium, alloy steels, and finally the more premium 300-series stainless steels. Special alloys such as Titanium, Inconel, Monel, and Hastelloy come at a significantly higher price, primarily due to their elevated levels of nickel, chromium, and molybdenum.

📞 Looking for competitive or discounted pricing on various Molybdenum products?

Feel free to reach out via email, phone, or WhatsApp.

📝 We also regularly update our price lists for steel products on our blog — check it out for the latest market insights!

Documents Provided – Domestic Sales or Export of Molybdenum Products

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Terms for Molybdenum Materials

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Molybdenum Materials

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Molybdenum Materials

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

Suppliers of Molybdenum Materials in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Exporters of Molybdenum Materials

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu