Description

A furnace is a device used for high-temperature heating. It is a container that is heated to a very high temperature, so that substances that are put inside it, such as metal, will melt or burn.

The name derives from Latin word fornax, which means oven. The heat energy to fuel a furnace may be supplied directly by fuel combustion, by electricity such as the electric arc furnace, or through induction heating in induction furnaces.

In metallurgy, several specialized furnaces are used. These include:

Furnaces used in smelters, including:

- The blast furnace, used to reduce iron ore to pig iron

Steelmaking furnaces, including:

- Puddling furnace

- Reverberatory furnace

- Bessemer converter

- Open hearth furnace

- Basic oxygen furnace

- Electric arc furnace

- Electric induction furnace

Furnaces used to remelt metal in foundries.

Furnaces used to reheat and heat treat metal for use in:

- Rolling mills, including tinplate works and slitting mills.

- Forges

Source: Wikipedia.org

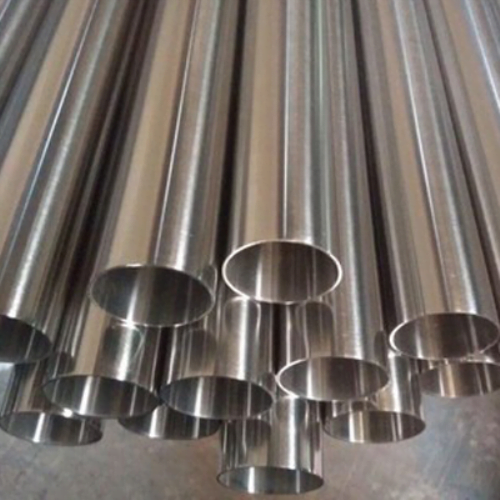

Why Buy AISI 317/317L, 1.4449/1.4438, UNS S31700/S31703 Seamless Pipes from Metallica Metals?

- Large Scale Enterprise – Metallica is biggest stock holding, manufacturing and processing company of SS 317/317L seamless pipes in India. Our large volume production, sales and purchase enables us to offer our products at the most competitive prices in the industry.

- Testing of Stainless Steel 317/317L Seamless Pipes– All SS 317/317L seamless pipes are subjected to hydrostatic test, eddy current test, chemical and mechanical tests during the various stages of production.

- Marking & Packing of Stainless Steel 317/317L Seamless Pipes – Marking on all pipes is as per the predefined rules in the specification.

- Test Certificates & Inspection of SS 317/317L Seamless Pipes – All our pipes are supplied with Mill test Reports, as per EN 10204 3.1. We can also allow third party inspection of all our products before delivery.

- We have own QC team to control the quality to meet particular standard strictly

- Short Lead Times – We can offer AISI 317/317L, 1.4449/1.4438, UNS S31700/S31703 seamless pipes with shortest delivery time.

- We can produce either standard or non-standard of the stainless steel 317/317L seamless pipes.

What is 317/317L Stainless Steel?

317 is a higher chromium, nickel and molybdenum version of 316 stainless designed principally for increased strength and corrosion resistance when compared with 304/304L and 316/316L.

317L is similar to 316 stainless steel but provides improved resistance to atmospheric corrosion, to many organic and inorganic chemicals and to food and beverages and can produce stronger welds due to the low carbon content. 317L’s molybdenum content increases to 3 to 4% from the 2 to 3% found in 316 and 316L. It has the same high strength and corrosion resistance as 317 steel but can produce stronger welds due to the low carbon content.

Alloy 317LMN and 317L are molybdenum-bearing austenitic stainless steel tube with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steel pipe such as Alloy 304. In addition, 317LMN and 317L alloys offer higher creep, stress-to-rupture, and tensile strengths at elevated temperatures than conventional stainless steels. All are low carbon or “L” grades to provide resistance to sensitization during welding and other thermal processes. Grade 317L is austenitic stainless steel that provides improved corrosion resistance over 304L and 316L stainless steels. The low carbon provides resistance to sensitization during welding and other thermal processes. 317L is non-magnetic in the annealed condition but may become slightly magnetic as a result of welding.

The “M” and “N” designations indicate that the compositions contain increased levels of molybdenum and nitrogen respectively. The combination of molybdenum and nitrogen is particularly effective in enhancing resistance to pitting and crevice corrosion, especially in process streams containing acids, chlorides, and sulfur compounds at elevated temperatures. Nitrogen also serves to increase the strength of these alloys. Both alloys are intended for severe service conditions such as flue gas desulfurization (FGD) systems.

In addition to excellent corrosion resistance and strength properties, the Alloys 316, 316L, and 317L Cr-Ni-Mo alloys also provide the excellent fabricability and formability which are typical of the austenitic stainless steel tubing .

Manufacturing Range for Stainless Steel 317/317L, 1.4449/1.4438, UNS S31700/S31703 Seamless or Welded Stainless Steel Pipes

| Product | ASTM A312 TP317/TP317L, 1.4449/1.4438, UNS S31700/S31703 Stainless Steel Pipes |

| Specification | ASTM A312 / A312M Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes |

| Type | Seamless & Welded |

| Size Range | Size: 1/8” to 24” (10.3mm to 610mm) – Seamless |

| Size:1/8” to 36” (10.3mm to 914mm) – Welded |

| 1/8” OD to 6” OD |

| Thickness | 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXH |

| Wall Thickness: 1mm to 60mm |

| Length | 6 Meter, Custom Lengths |

| Other Grades | TP304, TP304L, TP304LN, TP316, TP316L, TP316LN, TP317, TP317/317L, TP321, TP347, TP310S |

| Test Certificates | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| ASTM Reference Standards | - A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels.

- A370 Test Methods and Definitions for Mechanical Testing of Steel Products.

- A480 A480M Specification for general requirements for Flat-rolled stainless and Heat-Resisting steel plate, sheet, and strip.

- A632 Specification for Seamless and welded austenitic stainless-steel tubing (small-diameter) for general service.

- A1016 A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless-Steel Tubes.

- E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

|

| Testing | Mechanical Testing Such as Tensile of Area, Hardness Test, Chemical Analysis – Spectro Analysis, Positive Material Identification – PMI Testing, Flattening Test, Micro and MacroTest, Pitting Resistance Test, Flaring Test, Intergranular Corrosion (IGC) Test |

| Documents | Commercial Invoice, Packing List, Certificate of Origin, Fumigation Certificates, Raw Material Test Reports, Material Traceability Records, Quality Assurance Plan (QAP), Heat Treatment Charts, Test Certificates certifying NACE MR0103, NACE MR0175, Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Guarantee Letter, NABL approved Laboratory Test Reports |

Chemical Composition of ASTM A312 TP317/TP317L, 1.4449/1.4438, UNS S31700/S31703 Seamless or Welded Stainless Steel Pipes

| ELEMENT | 317 | 317L |

| NI | 11.0 – 15.0 | 11.0 – 15.0 |

| C | 0.08 max | 0.035 max |

| MN | 2.0 max | 2.0 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| SI | 1.0 max | 1.0 max |

| CR | 18.0 – 20.0 | 18.0 – 20.0 |

| MO | 3.0 – 4.0 | 3.0 – 4.0 |

Physical Properties of ASTM A312 TP317/TP317L, 1.4449/1.4438, UNS S31700/S31703 Seamless or Welded Stainless Steel Pipes

| 317 | 317L | Temperature in °C |

| Density | 7.99 g/cm³ | 7.99 g/cm³ | Room |

| Specific Heat | 0.12 Kcal/kg.C | 0.12 Kcal/kg.C | 22° |

| Melting Range | 1371 – 1421 °C | 1371 – 1421 °C | – |

| Modulus of Elasticity | 193 KN/mm² | 193 KN/mm² | 20° |

| Electrical Resistivity | 74 µΩ.cm | 79 µΩ.cm | Room |

| Coefficient of Expansion | 16.0 µm/m °C | 16.0 µm/m °C | 20 – 100° |

| Thermal Conductivity | 16.2 W/m -°K | 16.2 W/m -°K | 20° |

Mechanical Properties of ASTM A312 TP317/TP317L, 1.4449/1.4438, UNS S31700/S31703 Seamless or Welded Stainless Steel Pipes

| Grade | Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 317 | 75 | 30 | 35 |

| 317L | 75 | 30 | 40 |

Other Grades Comparision

| Grade | UNS | Composition, % in Max. |

| Designation | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | . . . | . . . |

| TP304LN | S30453 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | 0.10-0.16 |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–15 | 2.00–3 | . . . |

| TP316LN | S31653 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–13 | . . . | 0.10-0.16 |

| TP317L | S31700 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | . . . |

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . |

| Grade | UNS Designation | Tensile Strength, Min. Ksi [MPa] | Yield Strength, Min. Ksi [MPa] |

| TP304 | S30400 | 75 [515] | 30 [205] |

| TP304L | S30403 | 70 [485] | 25 [170] |

| TP316 | S31600 | 75 [515] | 30 [205] |

| TP316L | S31603 | 70 [485] | 25 [170] |

| TP317L | S31703 | 70 [485] | 25 [170] |

| TP321 | S32100 | 75 [515] | 30 [205] |

| TP347 | S34700 | 75 [515] | 30 [205] |

| TP347H | S34709 | 75 [515] | 30 [205] |