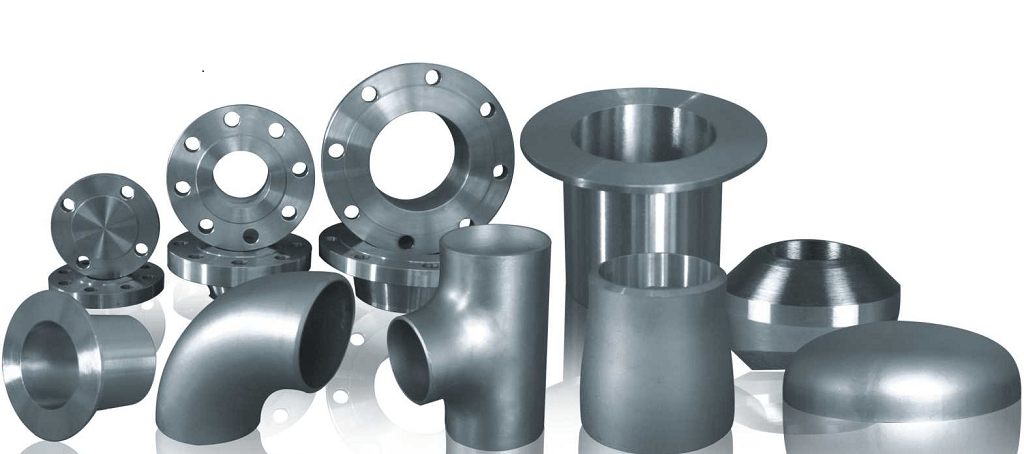

Zirconium Buttweld Pipe Fittings Manufacturers, Suppliers, Stockists – ASME B16.9, ASTM B653 Elbows, Tees, Caps, Olets, Reducers, Stub Ends, Crosses, Laterals, Return Bends

- We have around 30 years experience in manufacturing of zirconium buttweld pipe fittings in size ranging from 1/2” to 60”, schedule from Sch5s to SchXXS. Metallica specializes in manufacturing elbows, tee, reducer, caps, crosses, stub ends, etc conforming to ASME, ANSI, and DIN standard. We also produce custom size pipe fittings made according to drawings from our clients. Our products are widely used in oil & gas, petrochemical, refineries, power plant, shipbuilding, metallurgy, paper making and other industries.

- A zirconium buttweld pipe fitting is a type of pipe fitting, which is designed to be welded on site to connect pipes together. Welding of a zirconium buttweld pipe fitting to pipes or other fittings is generally done to allow change in direction of the piping system. Zirconium Buttweld fittings are generally identified or inquired in nominal pipe sizes with specified pipe schedule. Zirconium Buttweld fitting’s dimensions and tolerances are defined as per ASME B16.9 standard. All zirconium buttweld pipe fittings have beveled ends as per ASTM B653 standard. This helps create full penetration weld without any extra preparation needed for the zirconium buttweld fitting.

- Manufacturing zirconium buttweld fittings – A zirconium buttweld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dies. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties.

- Being one of the largest volume zirconium buttweld pipe fittings manufacturer and supplier in Mumbai, we can guarantee you the lowest prices. At Metallica Metals, we believe in selling in volume and increasing our customer base across the globe, enabling us to work on low margins. We have an extensive trader network across India, USA, Europe and the Middle East, who buy from us on a regular basis.

- In addition to traders, we have many EPC contractors, companies and end users in various industries as our customers. We are leading zirconium buttweld fittings suppliers for various applications ranging from low/medium/high pressure or temperatures.

- The major grades of Zirconium buttweld pipe fittings are Zr702 (R60702), Zr704 (R60704) and Zr705 (R60705). Zirconium alloys have low neutron absorption, therefore Zircaloy-2 (R60802) and Zircaloy-4 are designed to serve for nuclear industry which is stipulated with low Hf content < 0.01% per ASTM B353.

- ASME 16.9 covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought zirconium butt-welding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). The term “wrought” denotes fittings made of seamless or welded pipes, tubing, plates, or forgings. These fittings include long radius elbows, reducing elbows, long radius returns, short radius elbows, short radius 180° returns, 3D elbows, straight tees, straight crosses, reducing tees, reducing crosses, lap joint stub ends, caps, concentric reducers, and eccentric reducers.

Zirconium Buttweld Pipe Fittings Manufacturers and Suppliers

Zirconium Buttweld Dimensions

- Zirconium Butt Welded Pipe Fittings Dimensions refer to pipe size standards ANSI B36.10 and B36.19.

- Diameter range: 1″, 2″, 3″, 4″, 6″, 8″ and maximum 72″.

- Thickness range: Schedule 10, Schedule 40, Schedule 80, XS, XXS and SCH 160

- In the case of involving mounting dimensions of butt welded fittings, this will include the diameter in the NPS and the thickness in the schedule.

Production and Stock Range of Zirconium Buttweld Fittings

| Product | Zirconium Buttweld Fittings |

| Standards | ASTM B653/653M, ASME SB653 |

| Equivalent | 6.0702 |

| Surface | Brightly Machined |

| Size | NPS 1⁄2 through NPS 48 (DN 15 through DN 1200) |

| Grades | Grade R60702 (Zr702): unalloyed zirconium, Grade R60704 (Zr704): zirconium-tin alloy, Grade R60705 (Zr705): zirconium-niobium alloy, Grade R60706, Zircaloy-2 (R60802), Zircaloy-4 (R60804) |

| Delivery condition | Stress relief annealing, Recrystallization annealing |

| Testing & Inspection | Dimensional, Chemical analysis, Mechanical properties, Bending test, Flaring Test, Flattening Test, Hydrostatic Test, Eddy Current, Ultra Sonic |

Chemical Properties of Zirconium Buttweld Fittings

| Element | R60702 | R60704 | R60705 |

| Zirconium(+Hf) | ≥99.2 | ≥97.5 | ≥95.5 |

| Hafnium | ≤4.5 | ≤4.5 | ≤4.5 |

| Iron+Chromium | ≤0.2 | 0.2~0.4 | ≤0.2 |

| Tin | – | 1.0~2.0 | – |

| Hydrogen | ≤0.005 | ≤0.005 | ≤0.005 |

| Nitrogen | ≤0.025 | ≤0.025 | ≤0.025 |

| Carbon | ≤0.05 | ≤0.05 | ≤0.05 |

| Niobium | – | – | 2.0~3.0 |

| Oxygen | ≤0.16 | ≤0.18 | ≤0.18 |

Mechanical Properties of Zirconium Buttweld Fittings

| Tensile Strength, min. | Yield Strength, min. | Elongation | |||

| Grade | ksi | MPa | ksi | MPa | min. % |

| R60702 | 55 | 380 | 30 | 205 | 16 |

| R60704 | 60 | 415 | 35 | 240 | 14 |

| R60705 | 80 | 550 | 55 | 380 | 16 |

What is Zirconium?

Zirconium is a lustrous, greyish-white, soft, ductile and malleable metal that is solid at room temperature, though it is hard and brittle at lesser purities. Zirconium is a kind of active metal, which is easy to produce oxidation reaction. It can react with oxygen in the air at room temperature to form an oxide protective film. This protective film gives zirconium and zirconium alloys the best corrosion resistance. This oxide film can be further strengthened by heat treatment, and the surface microhardness can reach Vicat 480 (Rockwell C-scale 47). Most zircon is used directly in high-temperature applications. Even at low temperature, zirconium alloy has good ductility and strength similar to other engineering alloys. Oxygen is not only an indispensable component of oxide film, but also an alloy element to fill the structural gap and increase the strength of zirconium alloy. Zirconium alloy has no tendency from plasticity to embrittlement at low temperature. This material is refractory, hard and resistant to chemical attack. Because of these properties, zircon finds many applications, few of which are highly publicized.

With good nuclear properties and corrosion resistance, zirconium product is very important material for nuclear. Zirconium product mainly used for chemical equipment. For the higher cost, the zirconium tube use is not very common. In the chemical industry, it is mainly used in hydrochloric acid, molten alkali, acetic acid and other industries.

What is a Zirconium Seamless Buttweld Fitting?

- A seamless buttweld pipe fitting is made directly from a section of seamless pipe material, by applying heat and pressure to transform pipe directly into an elbow or other shape.

- A seamless fitting has no welded parts by itself, a characteristic demanded in some critical applications.

- By comparison, a regular buttweld fitting has one, two or more welds, depending on dimension, shape and manufacturing method.

- No weld means less risk of weld yield and porosities.

Properties of Zirconium Buttweld Fittings

- Long-term validity as compared to other materials

- Cost saving if it is well maintained

- Corrosion resistant

- High heat transfer efficiency

- Eliminates expensive downtime due to equipment failure

- Good heat conductor with Welding properties

Applications of Zirconium Buttweld Fittings

- Chemical processing, medical instruments etc.

- Aerospace Industry, Navigation, Smelting, Chemical plants and so on.

- Plate heat exchanger and condensers, Chemical and medical equipment

- Metallurgy

- Military Use

- Heat Exchanger

- Chemical Plant Applications

- Automotive components

- Cooling system parts

- For commercial Application (Hf ≤4.5%):

- UNS R60700 (Zr1): Commercially pure, Zr+Hf≥99.2

- UNS R60702 (Zr3): Commercially pure, Zr+Hf≥99.2

- UNS R60704 (Zirconium-Tin alloy): Zr-1.5%Sn, Zr+Hf≥97.5

- UNS R60705 (Zr5, Zirconium-Niobium alloy): Zr-2.5%Nb, Zr+Hf≥95.5, O≤0.18

- UNS R60706 (Zirconium-Niobium alloy): Zr-2.5%Nb, Zr+Hf≥95.5, O≤0.1

- For Nuclear Industry (Reactor grade, Hf ≤ 0.01%)

- UNS R60001 (Zr0):

- UNS R60802 (Zr2, Zircaloy2, Zirconium-Tin alloy): Zr-1.5Sn-0.15Fe-0.1Cr-0.05Ni

- UNS R60804 (Zr4, Zircaloy4, Zirconium-Tin alloy): Zr-1.5Sn-0.2Fe-0.1Cr

- UNS R60901 (Zirconium-Niobium alloy): Zr-2.5Nb, O-0.1%

- UNS R60904 (Zirconium-Niobium alloy): Zr-2.5Nb

- Zr-1Nb (Zr-1%Nb alloy)Related Zirconium Products

Standard Types of Zirconium Buttweld Fittings

- Zirconium Pipe Elbows – Steel elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends.

- Zirconium Pipe Bend – Pipe bend can be made of variety materials, like carbon steel, alloy steel, stainless steel, low temperature steel or high-performance steel, etc.

- Zirconium Pipe Tees – We can provide seamless tube tees and welding tube tees, which can also be divided into straight tees and reducing tees. Usually, the pipe tees have the same inlet and outlet sizes.

- Zirconium Pipe Cross – A pipe fitting, having four openings in the same place, at right angles to each other. A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or three inlets and one outlet.

- Zirconium End Caps – End Cap, Carbon Steel cap, Stainless Steel Caps, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches. Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- Zirconium Pipe Reducer – Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations.

- Zirconium Stub End – Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End.

- Zirconium Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Related Zirconium Products

| Zirconium Hollow Pipe | Zirconium Heater for High Temperature |

| Zirconium Seamless Pipe | Zr Zirconium Heat Exchanger Tube |

| Zirconium Bush Hex Pipe | Zirconium Eccentric Reducer |

| Zr 702 Zirconium Round Pipe | Zr 704 Zirconium Welded Pipe |

| Zirconium Alloy Round Pipe | Zirconium Rotating target |

| Zirconium Aero engine tube | Zirconium Custom Pipe |

| Zr 705 Zirconium Alloy Custom Pipe | Zirconium Thick Wall Pipe |

| Zirconium Elliptical and Oval Tube | Zirconium Thin Wall Pipe |

| Zirconium Pipe Fittings | Zirconium Forging |

| Zirconium Strips | Zirconium Fasteners |

| Zirconium Flex pipe | Zirconium Plates, Sheets and Bars |

| Zirconium Alloy Polished Pipe | UNS Zirconium lined pipe |

| Zirconium Exhaust Pipe | Zirconium Micro Tube |

| Zirconium Bar/Billet | Zirconium Wire/Welding Wire |

| Zirconium Boiler Tube | Zirconium Coil Tubing |

| Zirconium Capillary Tube | Zirconium U Shaped Tube |

| Zirconium Rods | Precision Zirconium Tubing |

| Zirconium Suppliers | Zirconium Slab |

| Zirconium Ingots | Zirconium Foil |

| Zirconium Metals | Zirconium Crucibles |

Testing & Inspection of Zirconium Buttweld Pipe Fittings

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Zirconium Buttweld Pipe Fittings

Prices for Zirconium buttweld pipe fittings are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of Zirconium buttweld pipe fittings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided at the time of Domestic Sales or Export of Zirconium Buttweld Pipe Fittings

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Basis for Zirconium Buttweld Pipe Fittings

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Zirconium Buttweld Pipe Fittings

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Suppliers of Zirconium Buttweld Pipe Fittings in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Export Sales of Zirconium Buttweld Pipe Fittings

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu