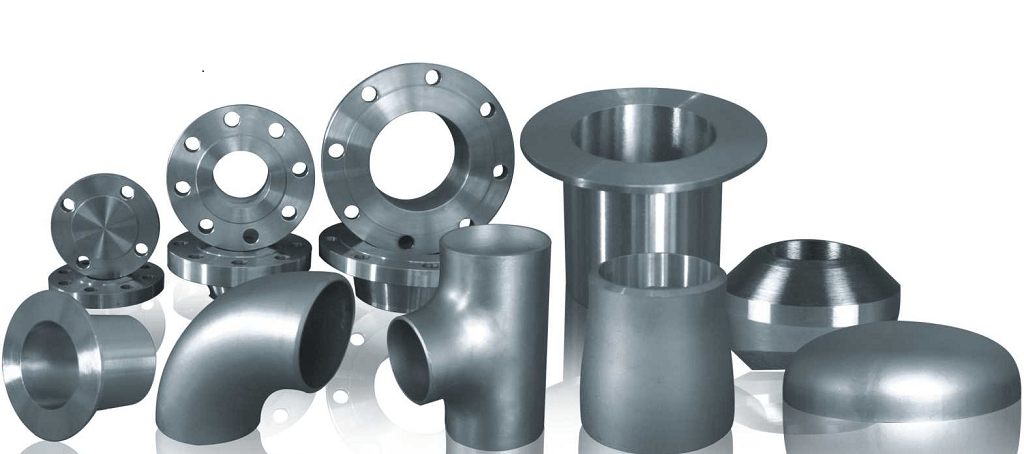

Tungsten Buttweld Pipe Fittings Manufacturers, Suppliers, Stockists – ASME B16.9 Elbows, Tees, Caps, Olets, Reducers, Stub Ends, Crosses, Laterals, Return Bends

- We have around 30 years experience in manufacturing of tungsten buttweld pipe fittings in size ranging from 1/2” to 60”, schedule from Sch5s to SchXXS. Metallica specializes in manufacturing elbows, tee, reducer, caps, crosses, stub ends, etc conforming to ASME, ANSI, and DIN standard. We also produce custom size pipe fittings made according to drawings from our clients. Our products are widely used in oil & gas, petrochemical, refineries, power plant, shipbuilding, metallurgy, paper making and other industries.

- A Tungsten buttweld pipe fitting is a type of pipe fitting, which is designed to be welded on site to connect pipes together. Welding of a Tungsten buttweld pipe fitting to pipes or other fittings is generally done to allow change in direction of the piping system. Tungsten Buttweld fittings are generally identified or inquired in nominal pipe sizes with specified pipe schedule. Tungsten Buttweld fitting’s dimensions and tolerances are defined as per ASME B16.9 standard. This helps create full penetration weld without any extra preparation needed for the Tungsten buttweld fitting.

- Manufacturing Tungsten buttweld fittings – A Tungsten buttweld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dies. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties.

- Being one of the largest volume tungsten buttweld pipe fittings manufacturer and supplier in Mumbai, we can guarantee you the lowest prices. At Metallica Metals, we believe in selling in volume and increasing our customer base across the globe, enabling us to work on low margins. We have an extensive trader network across India, USA, Europe and the Middle East, who buy from us on a regular basis.

- In addition to traders, we have many EPC contractors, companies and end users in various industries as our customers. We are leading Tungsten buttweld fittings suppliers for various applications ranging from low/medium/high pressure or temperatures.

- The major grades of Tungsten buttweld pipe fittings are Pure tungsten (99.95%), Tungsten copper (WCu), High density tungsten (WNiFe and WNiCu).

- ASME 16.9 covers overall dimensions, tolerances, ratings, testing, and markings for factory-made wrought Tungsten butt-welding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). The term “wrought” denotes fittings made of seamless or welded pipes, tubing, plates, or forgings. These fittings include long radius elbows, reducing elbows, long radius returns, short radius elbows, short radius 180° returns, 3D elbows, straight tees, straight crosses, reducing tees, reducing crosses, lap joint stub ends, caps, concentric reducers, and eccentric reducers.

Tungsten Buttweld Pipe Fittings Manufacturers and Suppliers

Standard Types of Tungsten Buttweld Fittings

- Tungsten Pipe Elbows – Steel elbow is used to be installed between two lengths of pipe or tube allowing a change of direction, usually these carbon steel elbows distinguished by connection ends.

- Tungsten Pipe Bend – Pipe bend can be made of variety materials, like carbon steel, alloy steel, stainless steel, low temperature steel or high-performance steel, etc.

- Tungsten Pipe Tees – We can provide seamless tube tees and welding tube tees, which can also be divided into straight tees and reducing tees. Usually, the pipe tees have the same inlet and outlet sizes.

- Tungsten Pipe Cross – A pipe fitting, having four openings in the same place, at right angles to each other. A pipe cross is a kind of pipe fitting. It is used in the place where four pipes meet together. The pipe cross may have one inlet and three outlets, or three inlets and one outlet.

- Tungsten End Caps – End Cap, Carbon Steel cap, Stainless Steel Caps, ANSI, ISO, JIS and DIN Standards, Measures 1/2 to 56 Inches. Based on different materials, pipe caps include carbon steel cap, stainless steel cap, and alloy steel cap etc.

- Tungsten Pipe Reducer – Pipe reducer are tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations.

- Tungsten Stub End – Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End.

- Tungsten Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Production and Stock Range of Tungsten Buttweld Fittings

| Material | Pure tungsten, W1, WAl1, W61, Carbonide Tungsten, Copper Tungsten, Nickel Tungsten |

| Size | Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″) |

| Schedule | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Purity | ≥99.95% |

| Surface | Pickled, Turned or Ground |

| Density | 18.2g~19.3g/cm3 |

| Technology | Powder metallurgy |

Tungsten Buttweld Fittings Grade Chart

| Grade | HA 190 | HA 1925 | HA 195 | HE 390 | HE 3925 | HE 395 | HE 397 | |

| Aerospace industry standards | ||||||||

| ASTM B777-15 | Non-magnetic Class 1 | Non-magnetic Class 2 | Non-magnetic Class 3 | Magnetic Class 1 | Magnetic Class 2 | Magnetic Class 3 | Magnetic Class 4 | |

| AMS 7725E | Type 1 Class 1 | Type 1 Class 2 | Type 1 Class 3 | Type 2 Class 1 | Type 2 Class 2 | Type 2 Class 3 | Type 2 Class 4 | |

| Typical properties* | Units | |||||||

| Tungsten | Nominal % | 90 | 92.5 | 95 | 90 | 92.5 | 95 | 97 |

| Binder | Ni/Cu | Ni/Cu | Ni/Cu | Ni/Fe | Ni/Fe | Ni/Fe | Ni/Fe | |

| Nominal density | g/cm3 | 17.1 | 17.5 | 17.9 | 17.1 | 17.5 | 18.1 | 18.5 |

| lb/in3 | 0.62 | 0.63 | 0.65 | 0.62 | 0.63 | 0.65 | 0.67 | |

| 0.2% proof stress | MPa | 675 | 650 | 680 | 645 | 645 | 660 | 660 |

| ksi | 100 | 95 | 100 | 95 | 95 | 95 | 95 | |

| Tensile strength | MPa | 805 | 830 | 805 | 875 | 900 | 910 | 915 |

| ksi | 116 | 120 | 116 | 126 | 130 | 131 | 132 | |

| Elongation on 25mm (1″) | % | 7 | 9 | 4 | 25 | 27 | 22 | 12 |

| Hardness | HRC | 24 | 24 | 24 | 27 | 24 | 24 | 25 |

*Properties may vary according to size and shape of part and production conditions. Figures shown are rounded and are typical for coupons (to fig.19 of ASTM E8) measured in accordance with ASTM B777-15; they are offered without warranty or guarantee. It is for the customer to satisfy itself of the suitability of the products for its own particular purposes and environmental conditions.

Tungsten Carbide Buttweld Fittings Grade Chart

| Tungsten Carbide Standard Grade Chart | |||||||

| Industry Code | FCC Grade | Binder Content & Type | Hardness (Ra) | Hardness (HV30) | Density (g/cm3) | Minimum Transverse Rupture Strength (psi) | Grain Size |

| General Purpose Grades | |||||||

| C2 | FC3 | 6% Co | 92 | 1585 | 14.95 | 3,20,000 | Fine |

| C1 | FC4 | 7.5% Co | 91 | 1460 | 14.7 | 3,30,000 | Fine |

| Metal Forming and Wear Grades | |||||||

| C10 | FC10 | 9% Co | 90 | 1360 | 14.6 | 3,60,000 | Medium |

| C11 | FC11 | 12% Co | 89.5 | 1315 | 14.3 | 3,90,000 | Medium |

| C12 | FC12 | 15% Co | 88 | 1190 | 14 | 4,20,000 | Medium |

| C13 | FC13 | 20% Co | 85 | 955 | 13.6 | 4,50,000 | Medium |

| C14 | FC25 | 25% Co | 83.2 | 760 | 13.15 | 4,35,000 | Medium |

| Submicron Grades | |||||||

| C3 | FC3M | 6% Co | 93 | 1740 | 14.95 | 3,75,000 | Submicron |

| C2 | FC10M | 10% Co | 91.9 | 1570 | 14.5 | 4,50,000 | Submicron |

| C1 | FC12M | 15% Co | 89.5 | 1315 | 14 | 5,30,000 | Submicron |

| Rotary Drilling and Mining Grades | |||||||

| C11 | FC10C | 10% Co | 88.6 | 1240 | 14.5 | 4,00,000 | Coarse |

| C12 | FC11C | 10% Co | 87.8 | 1175 | 14.5 | 4,25,000 | Coarse |

| Corrosion Resistant Grades | |||||||

| – | FC3N | 6% Ni | 91 | 1460 | 14.95 | 2,75,000 | Fine |

| – | FC10N | 9% Ni | 89.5 | 1315 | 14.6 | 2,90,000 | Fine |

| – | FC8N | 8.5% Ni | 91.5 | 1515 | 14.5 | 3,00,000 | Fine |

| – | FC82 | 15% Ni+Co | 89.9 | 1355 | 9 | 3,10,000 | Fine |

| Special grades to meet specific customer requirements are also available. | |||||||

Chemical Properties of Tungsten Buttweld Fittings

| MARK | OXIDE | CONTENT% | OTHER IMPURITY % | TUNGSTEN % | COLOR | ELECTRON WORK FUNCTION EV |

| WT10 | Tho2 | 0.8-1.2 | <0.2 | rest | yellow | 2.6 |

| WT20 | Tho2 | 1.8-2.2 | <0.2 | rest | red | 2.7 |

| WT30 | Tho2 | 2.8-3.2 | <0.2 | rest | purple | 3 |

| WT40 | Tho2 | 3.8-4.1 | <0.2 | rest | orange | 3.5 |

Most of tungsten chemical compounds are Tungsten oxides and tungsten trioxides(WO3), tungsten oxides are always named tungsten intermediate products – they are tungstic acid, ammonium paratungstate (APT, tungsten oxide content 88.5% );ammonium metatungstate (AMT), sodium tungstate, yellow tungsten oxide (YTO),blue tungsten oxide (BTO), tungsten trioxide (WO3), violet tungsten oxide (VTO). The other tungsten chemical compounds are most often used industrially as tungsten catalysts, there are tungstic anhydride, pure tungsten oxide, extra pure tungsten oxide (refined tungsten oxide) yellow-green tungsten oxide, Tungstic acid anhydride (Wolframic acid anhydrous, Wolframic acid anhydride), puratronic tungsten(vi) oxide, etc.

Mechanical, Physical and Thermal Properties of Tungsten Buttweld Fittings

| Atomic Number | 74 |

| Atomic Weight | 183.86 |

| Group Number | 6 |

| Electron Configuration | 1s2 2s2 2p6 3s2 3p6 4s2 3d10 4p6 5s2 4d10 5p6 6s2 4f14 5d4 |

| CAS Registry Number | 7440-33-7 |

| Atomic Volume | 9.53 |

| Lattice Type | Body Centered Cube |

| Lattice Constant at 20 ºC, Angstroms | 3.1585 |

| Natural Isotopes | 180, 182, 183, 184, 186 |

| Density @ 20 ºC (gm/cc) | 19.3 |

| Density @ 20 ºC (lb./cu. in.) | 0.697 |

| Melting Point ºC | 3410 |

| Boiling Point ºC | 5530 |

| Linear Coefficient of Expansion per ºC | 4.3 x 10E-6 |

| Thermal Conductivity @ 20 ºC (cal/cm/ºC/sec) | 0.4 |

| Specific Heat @ 20 ºC (cal/gram/ºC) | 0.032 |

| Electronegativity (eV) Pauling | 2.36 |

| Electronegativity (eV) Sanderson | 0.98 |

| Electronegativity (eV) Allred Rochow | 1.4 |

| Electrical Conductivity, % IACS | 31 |

| Electrical Resistivity @ 20 ºC (microhm-cm) | 5.5 |

| Electrical Resistivity @ 227 ºC (microhm-cm) | 10.5 |

| Electrical Resistivity @ 727 ºC (microhm-cm) | 24.3 |

| Electrical Resistivity @ 1727 ºC (microhm-cm) | 55.7 |

| Electrical Resistivity @ 2727 ºC (microhm-cm) | 90.4 |

| Electrical Resistivity @ 3227 ºC (microhm-cm) | 108.5 |

| Temperature Coefficient of Electrical Resistivity Per ºC (0 – 100 ºC) | 0.0046 |

| Tensile Strength @ Room Temp., psi | 100,000 – 500,000 |

| Tensile Strength @ 500 ºC, psi | 75,000 – 200,000 |

| Tensile Strength @ 1000 ºC, psi | 50,000 – 75,000 |

| Poisson’s Ratio | 0.284 |

| Hardness (Mineral) | 7.5 |

| Hardness (Vickers) | 343 |

| Hardness (Brinell) | 2570 |

| Reflectivity | 62% |

| Total Emissivity @ 1500 ºC | 0.23 |

| Total Emissivity @ 2000 ºC | 0.28 |

| Working Temperature, ºC | <1700 |

| Recrystallization Temperature, ºC | 1300 – 1500 |

What is Tungsten?

Tungsten is known as “wolfram” or “industrial tooth” or “industrial salt” because both of its melting point and specific gravity are much higher than other metals, while its hardness is only second to diamond. Tungsten alloy comes in two ranges – magnetic (the HE range) and non-magnetic (the HA range). With densities up to 18.5gcm, these grades are the prime choice for adding balance weights, ballast or vibration damping mass where space is limited.

The high density of tungsten alloy also delivers effective radiation shielding particularly against X-ray and gamma radiation. We also provide a specialist tungsten alloy grade (HM 490) for hot metal applications which offers good hot wear resistance.

All tungsten alloy grades are reasonably corrosion resistant in both acid and alkaline environments and can easily be plated or painted if necessary. They are easy to clean, non-toxic and non-radioactive.

Tungsten and tungsten products are mainly used in the fields of tungsten steel, tungsten materials, tungsten chemicals and cemented carbide, wherein cemented carbide has the hugest demand for tungsten. The demand of cemented carbide for tungsten occupies 72% in the European market, 66% in the Japanese market and 54% in the Chinese market.

Its good properties make tungsten an important raw material used in high-temperature applications. For example, good electrical conductivity makes high purity tungsten has a wild application in TFT-LCD screens.

Most tungsten is consumed for the production of tungsten carbide (WC), one of the hardest carbides. Tungsten alloys are also widely used in filaments in incandescent light bulbs, electric contacts, arc- welding electrodes, radiation shielding, and aerospace industry.

Magnetic tungsten alloy

Manufactured with a binder of iron and nickel, our magnetic alloys have a tungsten content of 90-97% by weight. These are suitable for many situations where a high density material is required.

Non-magnetic tungsten alloys

For non-magnetic alloys, copper and nickel are the binding agents, with a tungsten content in the range of 90-95%. These non-ferromagnetic alloys are used in a variety of applications, including medical scanners.

Technical data

Tungsten alloy conforms to the internationally recognized standard ASTM B777-15 and AMS 7725E the Aerospace Materials Specification. The non-magnetic grades have been proven to be non-magnetic through independent tests.

We deal in all types of Tungsten products such as:-

| Pure Tungsten (W) | Tungsten Alloy Radiation Shield |

| Tungsten Heavy Alloy | Tungsten Alloy Military Fittings |

| Tungsten Alloy Composites | Tungsten Alloy Counter Weight |

| Tungsten Carbide (WC) | Tungsten Alloy for Welding |

| Other Tungsten | Tungsten Putty Weight |

| Tungsten Bucking Bar | Tungsten Fluoride |

Properties of Tungsten Buttweld Fittings

- Tungsten is a lustrous and silvery white metal.

- The bulk metal resists attack by oxygen, acids and alkalis.

- Tungsten has the highest melting point of any metal.

- Tungsten is used in filaments in incandescent light bulbs, it is also used in electric contacts and arc-welding electrodes.

- Low electronic function

- Good conductivity

- Good electron emission ability

- Good mechanical cutting performance

- High elastic modulus, Low vapor pressure

- High recrystallization temperature

Difference Between Tungsten and Titanium

Which material is the strongest depends on where it is going to be used. There may be an application where a high yield strength is vital but the compressive strength is a non-factor. Understanding the application is essential to selecting the proper materials. In terms of tensile strength, tungsten is the strongest out of any natural metal (142,000 psi). But in terms of impact strength, tungsten is weak — it’s a brittle metal that’s known to shatter on impact. Titanium, on the other hand, has a tensile strength of 63,000 psi. But when you figure in titanium’s density and make a pound-for-pound comparison, it beats tungsten. Looking at titanium in terms of compression strength, it scores much lower on the Mohs scale of hardness.

Applications of Tungsten Buttweld Fittings

| Cell Phone | Tungsten alloy mobile cubes |

| Watch | Tungsten alloy watch bobs |

| Computers | Tungsten alloys heat sinks for PCB |

| Tungsten alloy heat base for PCB | |

| Dart Sets | Tungsten alloy dart billets, tungsten alloy dart barrels |

| Golf | Tungsten alloy golf clubs |

| Yacht | Tungsten alloy yacht balance, |

| Fishing | Tungsten alloy fishing sinkers |

| Hunting Gun | Tungsten alloy shots and hunting gun’s bullets’ balls |

| Tungsten alloy weights roller for meters, | |

| Racing Car & Motors | Tungsten alloy balances for racing car |

| Tungsten alloy crankshafts for motor & auto engines | |

| Home | Tungsten alloy Paper Weight. |

| Airplane | Riveting bucking bars for airplanes, |

| Submarines | Tungsten alloy seals for submarine |

| Tungsten alloy counterweigh , balance for submarine |

*Tungsten Products are also used in Chemical Industries, Cemented Carbide, Alloys, Electronics and Electrical Industries.

Types of Tungsten Products

| Black Tungsten Wire | Tungsten Furnace Elements | Tungsten Samples |

| Gold-Plated Tungsten Gauze | Tungsten Granules | Tungsten Shaving |

| Potassium-doped Tungsten Wire | Tungsten Grids | Tungsten Sheet |

| Tungsten Balance Weights | Tungsten Gauze | Tungsten Shot |

| Tungsten Balls | Tungsten Heat Shields | Tungsten Sleeves |

| Tungsten Bands | Tungsten Honeycomb | Tungsten Slugs |

| Tungsten Bar | Tungsten Ingot | Tungsten Specimens |

| Tungsten Baskets | Tungsten Insulated Wire | Tungsten Spheres |

| Tungsten Blocks | Tungsten Lump | Tungsten Sponge |

| Tungsten Boats | Tungsten Mesh | Tungsten Spring |

| Tungsten Boring Bars | Tungsten Metal | Tungsten Squares |

| Tungsten Chunk | Tungsten Needles | Tungsten Strands |

| Tungsten Coil | Tungsten Particles | Tungsten Strip |

| Tungsten Collimator Plates | Tungsten Parts | Tungsten Syringe Shields |

| Tungsten Concentrate | Tungsten Pellets | Tungsten Tape |

| Tungsten Conductor Paste | Tungsten Pieces | Tungsten Wafer |

| Tungsten Crucibles | Tungsten Pins | Tungsten Tube |

| Tungsten Cubes | Tungsten Plate | Tungsten Washer |

| Tungsten Cylinder | Tungsten Platens | Tungsten Wire |

| Tungsten Disc | Tungsten Powder | Tungsten Wire, Chromium-coated |

| Tungsten Electrodes | Tungsten Puck | Tungsten Wire, Gold-coated |

| Tungsten Filaments | Tungsten Ribbon | Tungsten Wire, Platinum-coated |

| Tungsten Flanges | Tungsten Rings | Tungsten Wool |

| Tungsten Foam | Tungsten Rod | Tungsten X-Ray Shields |

| Tungsten Foil | Tungsten Rods, Chrome-Plated | Tungsten Fluoride |

Testing & Inspection of Tungsten Buttweld Fittings

Testing (Destructive, Non Destructive)

| Positive Material Identification – PMI Testing | Hydrostatic Test |

| Chemical Analysis – Spectro Analysis | Hydrogen-Induced Cracking (HIC) Test |

| Mechanical Testing Such as Tensile, Elongation, Reduction of Area | Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177 |

| Micro Test | Radiography Test |

| Macro Test | Dye Penetrant Test (DP Test) |

| Hardness Test | Ultra Sonic Test (UT) |

| Pitting Resistance Test | Eddy Current Testing |

| Intergranular Corrosion (IGC) Test | Impact Test |

| Flaring Test | Bend Test |

| Flattening Test |

Inspection

- Our internal inspection reports would be provided for all the goods before shipment.

- Buyers or their associates are most welcome to visit us for personal inspect

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, BVIS, SGS, Llyods, DNV etc.

Prices for Tungsten Buttweld Fittings

Prices for Tungsten Buttweld Fittings are directly co related to prices of the raw materials such as iron ore, metal scrap, chromium, nickel and various other alloying elements. The production cost of heat resistant stainless steel and nickel alloy plates is high as they contain high amount of nickel and chromium. Meanwhile, mild steel material is among the lowest cost steel available, followed by carbon steel, 400 series stainless steels, aluminium, alloy steel, and 300 series stainless steel. Special alloys such as titanium, Inconel, Monel and Hastelloy cost very high as the nickel, chromium and moly content is very high.

For special and discounted prices for various types of Tungsten Buttweld Fittings, please feel free to contact us through email, phone or whatsapp.

We are also regularly publishing our price list for various steel products on our blog.

Documents Provided – Domestic Sales or Export of Tungsten Buttweld Fittings

| Certificate of Origin | Raw Material Test Reports |

| Commercial Invoice | Heat Treatment Charts |

| Packing List | Quality Assurance Plan (QAP) |

| Fumigation Certificates | NABL approved Laboratory Test Reports |

| Letter of Guarantee | Material Test Certificates |

| ROHS Certificate | Certificate of Compliance/Conformity |

Price Terms for Tungsten Buttweld Fittings

We can offer any of the following price basis depending on your requirement:

- Ex-works

- FOR Site in India

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Delivery Time of Tungsten Buttweld Fittings

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Marking & Packing of Tungsten Buttweld Fittings

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut piece of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and picture of the product from which it is cut.

- All goods are packed in wooden cases or pallets.

Suppliers of Tungsten Buttweld Fittings in India

Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Jaipur, Visakhapatnam, Kanpur, Nagpur, Lucknow, Thane, Bhopal, Indore, Pimpri Chinchwad, Patna, Vadodara, Ghaziabad, Ludhiana, Agra, Nashik, Faridabad, Meerut, Rajkot, Kalyan-Dombivli, Vasai-Virar, Varanasi, Srinagar, Aurangabad, Dhanbad, Amritsar, Navi Mumbai, Allahabad, Howrah, Ranchi, Gwalior, Jabalpur, Coimbatore, Vijayawada, Jodhpur, Madurai, Raipur, Chandigarh, Guntur, Guwahati, Solapur, Hubli–Dharwad, Mysore, Tiruchirappalli, Bareilly, Moradabad, Tiruppur, Gurgaon, Aligarh, Jalandhar, Bhubaneswar, Salem, Mira-Bhayandar, Warangal, Jalgaon, Kota, Bhiwandi, Saharanpur, Gorakhpur, Bikaner, Amravati, Noida, Jamshedpur, Bhilai, Cuttack, Firozabad, Kochi, Nellore, Bhavnagar, Dehradun, Durgapur, Asansol, Rourkela, Nanded, Kolhapur, Ajmer, Akola, Gulbarga, Jamnagar, Ujjain, Loni, Siliguri, Jhansi, Ulhasnagar, Jammu, Sangli-Miraj & Kupwad, Mangalore, Erode, Belgaum, Ambattur, Tirunelveli, Malegaon, Gaya, Thiruvananthapuram, Udaipur, Kakinada, Davanagere, Kozhikode, Maheshtala, Rajpur, Sonarpur, Rajahmundry, Bokaro, South Dumdum, Bellary, Patiala, Gopalpur, Agartala, Bhagalpur, Muzaffarnagar, Bhatpara, Panihati, Latur, Dhule, Tirupati, Rohtak, Sagar, Korba, Bhilwara, Berhampur, Muzaffarpur, Ahmednagar, Mathura, Kollam, Avadi, Kadapa, Kamarhati, Sambalpur, Bilaspur, Shahjahanpur, Satara, Bijapur, Kurnool, Rampur, Shimoga, Chandrapur, Junagadh, Thrissur, Alwar, Bardhaman, Kulti, Nizamabad, Parbhani, Tumkur, Khammam, Ozhukarai, Bihar Sharif, Panipat, Darbhanga, Bally, Aizawl, Dewas, Ichalkaranji, Karnal, Bathinda, Jalna, Eluru, Barasat, Kirari Suleman Nagar, Purnia, Satna, Mau, Sonipat, Farrukhabad, Durg, Imphal, Ratlam, Hapur, Arrah, Anantapur, Karimnagar, Etawah, Ambarnath, North Dumdum, Bharatpur, Begusarai, New Delhi, Gandhidham, Baranagar, Tiruvottiyur, Pondicherry, Sikar, Thoothukudi, Rewa, Mirzapur, Raichur, Pali, Ramagundam, Haridwar, Vijayanagaram, Tenali, Nagercoil, Sri Ganganagar, Karawal Nagar, Mango, Thanjavur, Bulandshahr, Uluberia, Katni, Sambhal, Singrauli, Nadiad, Secunderabad, Naihati, Yamunanagar, Bidhannagar, Pallavaram, Bidar, Munger, Panchkula, Burhanpur, Raurkela Industrial Township, Kharagpur, Dindigul, Gandhinagar, Hospet, Nangloi Jat, Malda, Ongole, Deoghar, Chapra, Haldia, Khandwa, Nandyal, Morena, Amroha, Anand, Bhind, Bhalswa Jahangir Pur, Madhyamgram, Bhiwani, Berhampore, Ambala, Morbi, Fatehpur, Raebareli, Mahaboobnagar, Chittoor, Bhusawal, Orai, Bahraich, Vellore, Mehsana, Raiganj, Sirsa, Danapur, Serampore, Sultan Pur Majra, Guna, Jaunpur, Panvel, Shivpuri, Surendranagar Dudhrej, Unnao, Chinsurah, Alappuzha, Kottayam, Machilipatnam, Shimla. Adoni, Udupi, Katihar, Proddatur, Saharsa, Hindupur, Sasaram, Hajipur, Bhimavaram, Kumbakonam, Dehri, Madanapalle, Siwan, Bettiah, Guntakal, Srikakulam, Motihari, Dharmavaram, Gudivada, Phagwara, Narasaraopet, Suryapet, Miryalaguda, Tadipatri, Karaikudi, Kishanganj, Jamalpur, Ballia, Kavali, Tadepalligudem, Amaravati, Buxar, Jehanabad, Aurangabad, Gangtok

Exporters of Tungsten Buttweld Fittings

- America: Antigua and Barbuda, Argentina, Aruba, Bahamas, Barbados, Belize, Bermuda, Bolivia, Brazil, Canada, Cayman Islands, Chile, Colombia, Costa Rica, Cuba, Dominica, Dominican Republic, Ecuador, El Salvador, Grenada, Guatemala, Guyana, Haiti, Honduras, Jamaica, Mexico, Nicaragua, Panama, Paraguay, Peru, Puerto Rico, Suriname, Trinidad and Tobago, United States, Uruguay, Venezuela

- Europe – Albania, Andorra, Austria, Belarus, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Euro area, Faroe Islands, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Isle of Man, Italy, Kosovo, Latvia, Liechtenstein, Lithuania, Luxembourg, Macedonia, Malta, Moldova, Monaco, Montenegro, Netherlands, Norway, Poland, Portugal, Romania, Russia, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey, Ukraine, United Kingdom

- Africa – Algeria, Angola, Benin, Botswana, Burkina Faso, Burundi, Cameroon, Cape Verde, Central African Republic, Chad, Comoros, Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Gabon, Gambia, Ghana, Guinea, Guinea Bissau, Ivory Coast, Kenya, Lesotho, Liberia, Libya, Madagascar, Malawi, Mali, Mauritania, Mauritius, Morocco, Mozambique, Namibia, Niger, Nigeria, Republic of the Congo, Rwanda, Sao Tome and Principe, Senegal, Seychelles, Sierra Leone, Somalia, South Africa, South Sudan, Sudan, Swaziland, Tanzania, Togo, Tunisia, Uganda, Zambia, Zimbabwe

- Asia – Afghanistan, Armenia, Azerbaijan, Bahrain, Bangladesh, Bhutan, Brunei, Cambodia, China, East Timor, Georgia, Hong Kong, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Laos, Lebanon, Macao, Malaysia, Maldives, Mongolia, Myanmar, Nepal, Oman, Palestine, Philippines, Qatar, Saudi Arabia, Singapore, South Korea, Sri Lanka, Syria, Taiwan, Tajikistan, Thailand, Turkmenistan, United Arab Emirates, Uzbekistan, Vietnam, Yemen

- Australia – Australia, Fiji, Kiribati, New Caledonia, New Zealand, Papua New Guinea, Samoa, Solomon Islands, Tonga, Vanuatu