What is Stainless Steel?

Stainless steel is the generic name for a number of different steels used primarily for their resistance to corrosion. Stainless steels are produced by adding at least 11% chromium to steel to produce a thin passive protective layer of Cr2Q3, which promotes corrosion resistance. This is improved by further increasing the chromium content.

What are the Types of Stainless Steel?

Four basic groups of stainless steel are available:

- Ferritic Stainless Steels: – This group contains between 16 and 30 per cent chromium, with a maximum of 0.1 per cent carbon. These materials can be welded with a preheat of 150°C and the use of the 25 per cent chromium and 20 per cent nickel core wire electrode. Sometimes combination welds are made, with the final layers being completed with electrodes of even higher chromium content (up to 30 per cent), in order to give the surface an extremely high resistance to corrosion. A post heat at 730°C should be performed immediately after welding to prevent brittleness.

- Martensitic Stainless Steels: – Martensitic grades contain similar amounts of chromium, but more carbon than ferritics and possibly other additions such as molybdenum to increase hardenability and strength. Can be heat treated. This group contains from 11.5 to 14 per cent chromium and from 0.2 to 0.4 per cent carbon. Such steels are difficult to weld because they can form the very hard martensitic structure regardless of the cooling rate. They are known as air-hardening steels. They can be welded by preheating to around 350°C and using a 25 per cent chromium and 20 per cent nickel flux coated electrode. A post-heat of 750°C usually ensures acceptable ductility.

- Austenitic Stainless Steels: – Austenitic grades contain between 17-25% Cr, 7-20% nickel and in some instances molybdenum. They are face-centred cubic in structure, nonmagnetic and can be formed and welded more easily than ferritics. Austenite (gamma) phase field is extended to room temperature. Most corrosion resistant.

- Typical composition: 18% chromium, 8% nickel, 0.15% carbon. Remainder: Fe (S. & P. kept below 0.045%), Ti or Nb.

- Effect of elements on properties: The nickel is added to give toughness and may be increased to 11.5% to prevent work hardening (for rivets and fastenings). The chromium is added to give corrosion resistance. In addition titanium or niobium is often added to prevent inter-granular corrosion (weld decay) in the following proportions: Ti – 5 x C content, Nb = 10 x C content.

| Approximate melting temperature | 1420°C to 1395°C |

| Hardness | 170 Hv (water quench from 1000°C) |

| Tensile strength | Approx. 620 N/mm² |

| Yield point | Approx. 280 N/mm² |

| Mass | 7.92 g/cm³ at +20°C |

| Coefficient of linear expansion | 0.02 °C |

- How to identify: This iron-based alloy has a characteristic silver lustre imparted to it by the amount of chromium and nickel. It is the chromium which combines with oxygen and rapidly forms a very thin oxide which is continuous and stable and impervious to further attack by the atmosphere. The thickness of this oxide film increases with the degree of polish to give a mirror finish. These steels give a dull red spark when touched on a grinding wheel.

- Corrosion: The corrosion resistance is excellent in most environments but solutions of nitric, hydrofluoric and sulphuric acid will attack 18/8 stainless steel. These acid solutions are used to remove the oxide scale which result from strongly heating the material in air. The term used for this treatment is pickling.

- Types of Corrosion:

- Inter Crystalline Corrosion (Weld Decay)

- Pitting Corrosion

- Stress Corrosion

- Duplex Stainless Steels: – Duplex stainless steels were developed to provide the strength of ferritics, but with improved corrosion resistance. They contain about 22% Cr, 5% Ni, and possibly molybdenum. Ferrite + Austenite

- Precipitation-Hardening (PH) Stainless Steels: – Ultra high strength due to precipitation hardening.

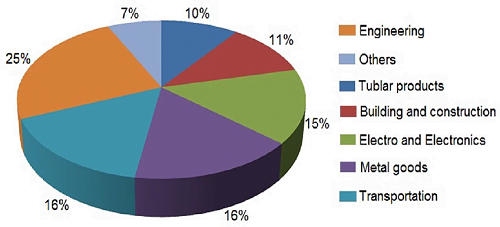

Applications of Stainless Steel

Stainless steels are used extensively in food and drink production and the chemical and energy industries; martensitics are used for cutlery and other cutting tool manufacture.

Properties of Stainless Steel

- Aesthetic qualities: it can be polished to a satin or mirror finish;

- “Dry corrosion” occurs to steel at higher temperatures where it oxidises or scales up. Stainless steel is far more resistant to this than ordinary carbon steel and grades such as 310 (25% chromium 20% nickel) were specifically developed for use at high temperatures;

- Non-contamination of the liquids stainless comes into contact with, because there is no coating to break down and dissolve;

- Weight savings; as thinner sections and more innovative design structures can be used, with cost savings on foundations and platform weights;

- Many anti-corrosion coatings are fire hazards or the materials themselves have a low melting point.

Advantages of Stainless Steel

- Does not react or influence other materials.

- Used extensively in the food/catering divisions.

- Used widely in the medical world. E.g. Plates and screws to repair bones.

- Aesthetic Qualities: It can be polished to a satin or mirror finish.

- Dry Corrosion: Stainless steel is far more resistant to this than ordinary carbon steel.

- Grades such as 310 (25% chromium 20% nickel) were specifically developed for use at high temperatures.

- Non-contamination: Because there is no coating to break down and dissolve there is no contamination of liquids that stainless steel comes in contact with.

- Weight: As thinner sections and more innovative design structures can be used, giving cost savings on foundations and platform weights.

What are the Various Grades of Stainless Steel?

| Austenitic Stainless Steels | |

| 301 | High strength for roll formed structural components |

| 304, 304L, 304H | Standard 18/8 grades |

| 310, 310S, 310H | High temperature resistant grades |

| 316, 316L, 316H | Improved resistance to pitting corrosion in chloride environments |

| 321, 321H, 347 | Stabilized grades for heavy section welding and high temperature applications |

| 904L | High resistance to general corrosion, pitting and stress corrosion cracking |

| Ferritic Stainless Steels | |

| 409 | Automotive exhaust grade – weld stabilized |

| 430, 430F | Resistant to mildly corrosive environments |

| 439 | Resistant to mildly corrosive environments – weld stabilized |

| 444 | A ferritic alternative to grade 316 / 316L – weld stabilized |

| Duplex Stainless Steels | |

| 2101 | Lean duplex – economical alternative to 304 and 316 |

| 2304 | Duplex alternative to grade 316 |

| 2205 | Standard duplex stainless steel – high resistance to pitting and stress corrosion |

| 2507 | Super duplex with very high resistance to pitting and stress corrosion |

| Martensitic Stainless Steels | |

| 410 | Standard martensitic grade for low-duty hardened applications |

| 416 | Free-machining bar grade |

| 420 | Higher hardness martensitic grade for cutlery, cutting tools and dies |

| 431 | High hardness and toughness grade, primarily for shafting |

| 440A, 440B, 440C | Very high hardness grades used in cutting tools |

| Precipitation Hardening Stainless Steel | |

| 630 | (17-4PH) High strength shafting grade |

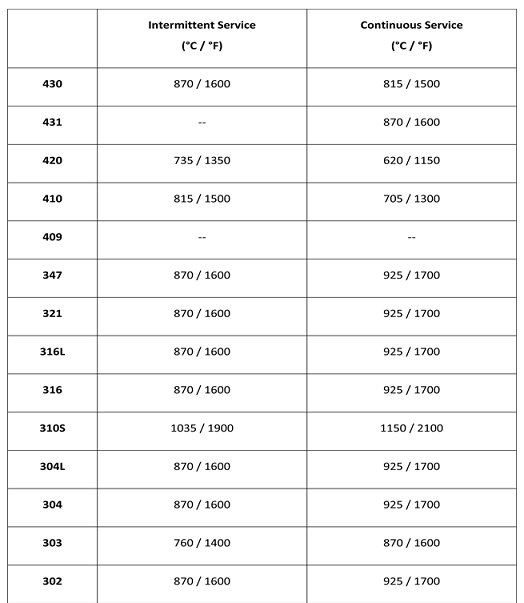

What are the Maximum Operating Temperatures of Stainless Steel Grades?

Stainless steels have good strength and good resistance to corrosion and oxidation at elevated temperatures. Stainless steels are used at temperatures up to 1700° F for 304 and 316 and up to 2000 F for the high temperature stainless grade 309(S) and up to 2100° F for 310(S).

[Image Source: From Web]

Influence of Alloying Elements on the Properties of Stainless Steel

| Element | Effect on Stainless Steel |

| Chromium | Forms a passive film with oxygen that prevent the further diffusion of oxygen into the surface |

| Composition needs to contain at least 10.5% to be a stainless steel | |

| Nickel | Increases ductility and toughness. Increase corrosion resistance to acids |

| Additon creates non-magnetic structure | |

| Molybdenum | Increases pitting and crevice corrosin resistance. Increase resistance to chlorides |

| Copper | Increase corrosion resistance to sulfuric acid |

| Manganese | Substitute for nickel (200 series) |

| Titanium/Niobium | Ties up carbon and prevents inter-granular corrosion in welded zone of ferritic grades |

| Nitrogen | Increase strength and corrosion resistance in austenitic and duplex grades |

| Silicon | Improves resistance to high temperature scaling |

| Sulfur | Usually kept low excet for “free-machining” grades |

| Carbon | Usually kept low. Used in martensitic grades to increase strength and hardness |

Comparative International Grades of Stainless Steel

| British | French | German | Italian | Japanese | Swedish | USA |

| 304S21 | Z12CN17.08 | 1.431 | X12CrNi 17 07 | SUS301 | 14 23 31 | 301 |

| 304S31 | SUS302 | 14 23 32 | 302 | |||

| 304S15304S16 | Z8CN18.09 | 1.4301 | X5CrNi 18 10 | SUS301 | 14 23 33 | 304 |

| 304S11 | Z2CN18.10 | 1.4306 | X2CrNi 18 11 | SUS304L | 14 23 52 | 304L |

| 305S19 | Z8CN18.12 | X8CrNi 18 12 | SUS305 | 305 | ||

| 309S24 | Z15CN24.13 | X16CrNi 23 14 | SUS309 | 309 | ||

| 310S24 | Z12CN25.20 | 1.4845 | Z22CrNi 25 20 | SUS310S | 14 23 61 | 310 |

| 315S16 | 14 23 40 | |||||

| 316S31316S33 | Z6CND17.11 | 1.44011.4436 | X8CrNiMo 17 13 | SUS316 | 14 23 4314 23 47 | 316 |

| 316S11316S13 | Z2CND17.12 | 1.44041.4435 | X2CrNiMo 17 12 | SUS316L | 14 23 5314 23 48 | 316L |

| 317S12 | Z2CND19.15 | 1.4435 | X2CrNiMo 18 16 | SUS317L | 14 23 67 | 317L |

| 317S16 | 1.4436 | SUS317 | 14 23 66 | 317 | ||

| 320S31320S33 | Z8CND17.12 | 1.45711.4573 | 14 23 50 | |||

| 321S31 | Z6CNT18.12 | 1.4541 | X6CrNiTi 18 11 | SUS321 | 14 23 37 | 321 |

| 347S31 | Z6CNNb18.11 | 1.4558 | X6CrNiNb 18 11X8CrNiNb 18 11 | SUS347 | 14 23 38 | 347 |

| 403S17 | Z6C13 | 1.4 | X6Cr13 | SUS403 | 14 23 01 | 403 |

| 405S17 | Z6CA13 | 1.4002 | Z6CrA1 13 | SUS405 | 405 | |

| 409S19 | 1.4512 | 409 | ||||

| 430S17 | Z8C17 | 1.4016 | X8Cr 17 | SUS430 | 14 23 20 | 430 |

| 434S17 | Z8CD17.01 | 1.4113 | X8CrMo 17 | SUS434 | 14 23 25 | 434 |

| 410S21 | Z12C13 | 1.40061.4024 | X12Cr 13 | SUS410 | 13 23 02 | 410 |

| 410S45 | Z30C13 |

Leave A Comment