What is the Manufacturing Process for Welded Pipes?

Welded Pipes are manufactured from plate or from continues coil or strips. To manufacture welded pipe, first, plate or coil is rolled in the circular section with the help of plate bending machine or by a roller in the case of continuous process.

At the start of the welded pipe manufacturing process, so called slabs or billets are cast in a steel mill. Dependent on the external dimensions and wall thickness there are different methods of producing welded pipes and tubes. The welded pipes are produced by three types of welding processes:

Electric Resistance Welding (ERW), Fusion Welding (EFW) and Double Submerged Arc Welding (DSAW). In the ERW and EFW manufacturing process welded pipes are formed by hot or cold rolling plate and welding the seam. In order to keep the outside (O.D.) surface of a welded pipe smooth and uniform a cutting tool called scarfing blade is used to remove the weld flash. Scarfing from the inside (I.D.) welded flash is also possible. With a heat treating at the end of the manufacturing process the weld zone of the steel pipe can be made less visible. Due to the weld seam lower operating pressures are stated in accordance with ASME compared to seamless pipes. In general welded tubes possess tighter dimensional tolerances than seamless pipes and are less costly if produced in same quantities.

ERW or HFI / HFW Pipe Manufacturing

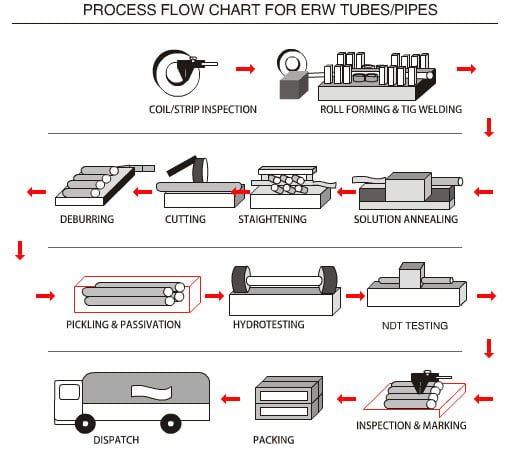

ERW Pipes and Tubes Manufacturing Process [Image Source: from web]

A process for producing welded tubes is Electric Resistance Welding (ERW) also known as Contact Welding. The manufacturing starts by cold-forming a coiled plate of steel with eligible thickness and certain width into a cylindrical shape. As the cylindrical plates come together, an electric current using heat merges the abutting edges together to create the final product.

In HFW/HFI welding, a high-frequency current is used to create weld joints. Whereas, in EFW welding process; the external high energy electric arc is used to create a weld joint. Once the welding is done, the excess weld material from outside and inside of the pipe is removed with the help of trimmer tools. However, the product is still often referred to as ERW pipe, even though the weld may have been produced by the HFI / HFW (High Frequency Welded Pipe) process.

EFW Pipe Manufacturing

EFW Manufacturing Process [Image Source: from web]

DSAW Pipe Manufacturing

Spiral SAW Pipe Manufacturing Process [Image Source: from web]

The process of producing Double Submerged Arc Welded Pipes first contains forming steel plates into cylindrical shapes. Later on the edges of the rolled plate are forged so that v-shaped notches are on the exterior and interior area of the seam. Then the pipe seam is being welded by an arc welder submerged under flux. In the case of high thickness pipe, multiple pass welding is done.

In a Spiral SAW pipe, steel plate from the de-coiler is formed in a spiral loop. This spiral loop is then welded from inside and outside of the pipe. Because of the method of manufacture, a wide variety of diameters can be produced. Spiral saw pipes are used for low-pressure services.

Whereas Straight SAW pipes are used for medium to high-pressure services. Spiral saw pipes are less costly compared to straight saw pipe.

Once the welding is completed, Weld seams are subjected to various non-destructive testing such as RT & UT to ensure the soundness of the weld material; pipes are hydro tested to ensure strength and ability to remain leak proof under pressure. In the last stage of inspection, the pipe is checked visually and dimensionally by competent inspection engineer. He will ensure that pipe is meeting the code, standard, and specification requirements. Once the Inspection engineer cleared the pipe, it will mark as per the standard requirements & send for the packaging. Once the Inspection engineer cleared the pipe; visually and dimensionally, it will mark as per the standard requirements & send for the packaging.

Metallica is a leading manufacturer and supplier of welded pipes and tubes providing an extensive selection of all grades and dimensions to the oil & gas, petrochemical, chemical and power industries. We work closely together with certified pipe manufacturers from around the world and have a huge range of different welded pipes constantly on stock ranging from Electric Resistance Welded (ERW) Pipes, Fusion Welded (EFW) Pipes to Double Submerged Arc Welded (DSAW) Pipes.

Leave A Comment