Unraveling the Mystery: Your Top Questions About Seamless vs. Welded Pipes Answered!

Ever wondered what makes a pipe tick? When it comes to industrial applications, construction, and even your home’s infrastructure, pipes are the unsung heroes. But not all pipes are created equal! The choice often boils down to two main types: seamless and welded.

If you’ve found yourself scratching your head trying to figure out the difference, you’re in the right place! We’ve gathered the most frequently asked questions and provided clear, concise answers to help you navigate the fascinating world of pipes. Let’s dive in!

🏗️ The Foundation: How Are They Made?

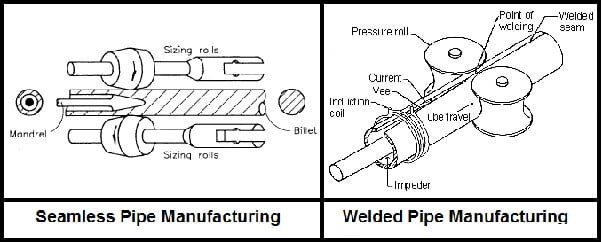

This is where the story of seamless and welded pipes truly begins – in their manufacturing process. Understanding this fundamental difference illuminates many of their subsequent characteristics.

Q1: What’s the core difference in how seamless and welded pipes are manufactured?

A: Think of it this way: Seamless pipes are born from a solid piece of steel, like carving a tunnel through a mountain. A solid steel billet is heated and then pierced and rolled until it forms a hollow tube – no seams, no welds, just pure, uninterrupted steel.

Welded pipes, on the other hand, are like a meticulously crafted scroll. A flat sheet or coil of steel is bent into a cylindrical shape, and then its edges are joined together using a welding process to create a strong, continuous seam.

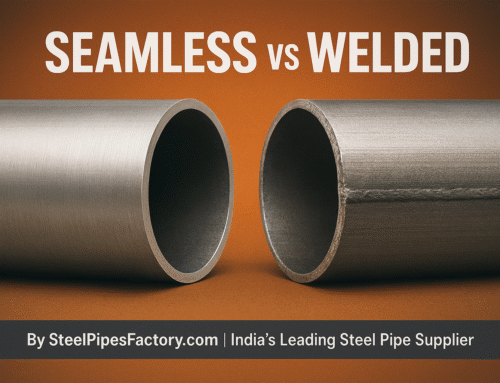

Q2: Does a welded pipe always have a visible seam?

A: Absolutely! By definition, a welded pipe’s identity is tied to its seam. While modern welding techniques make these seams incredibly strong and sometimes less prominent, the weld joint is an inherent and permanent part of its structure. The seam might run straight along the pipe (like in ERW – Electric Resistance Welded or LSAW – Longitudinal Submerged Arc Welded pipes) or spiral around it (SSAW – Spiral Submerged Arc Welded pipes), but it’s always there.

Q3: You mentioned a “steel billet” for seamless pipes. What exactly is that?

A: Great question! A steel billet is essentially the starting block for seamless pipes. It’s a solid, semi-finished length of metal, typically with a circular cross-section. Imagine a thick, sturdy steel log that will eventually be transformed into a hollow tube.

💪 Performance Powerhouse: Strength, Pressure and Consistency

When pipes are put to work, their performance characteristics become paramount. Here’s how seamless and welded pipes stack up in terms of strength, ability to handle extreme conditions, and structural consistency.

Q4: Which type of pipe is generally stronger, and what makes it so?

A: When it comes to brute strength, seamless pipes typically take the crown. Why? Because there’s no weld seam! That seam, no matter how well-made, can be a potential point of weakness or a different metallurgical structure. With seamless pipes, you get uniform structural integrity all the way around, meaning stress is distributed more evenly.

Q5: Which pipe is better suited for handling high pressure and extreme temperatures?

A: For demanding environments involving high pressure and extreme temperatures, seamless pipes are the go-to choice. Their inherent uniform strength, free from weld stresses or potential imperfections, makes them incredibly reliable when the stakes are high. Think critical applications where failure isn’t an option.

Q6: How consistent is the wall thickness in both types of pipes?

A: Interestingly, this is an area where welded pipes often have an advantage. Since they start as a flat steel plate or coil, which typically has a very uniform gauge, the resulting welded pipe tends to have a more consistent wall thickness. Seamless pipes, due to the piercing and rolling process of a solid billet, can sometimes exhibit slight variations in wall thickness.

Q7: Is one type of pipe more prone to corrosion than the other?

A: Generally, welded pipes can be more susceptible to corrosion, particularly at the weld seam itself. The welding process can sometimes alter the metallurgical properties of the steel in the weld zone and the adjacent heat-affected zone, potentially making these areas more vulnerable to corrosive agents than the parent metal. Seamless pipes, with their homogeneous structure, usually offer more uniform corrosion resistance.

💸 Practicalities: Cost, Size and Availability

Beyond performance, the practical aspects of cost and what’s available on the market often influence decision-making.

Q8: Which type of pipe is typically more expensive?

A: In most cases, seamless pipes are more expensive. The manufacturing process for seamless pipes, involving specialized equipment to pierce and roll a solid billet, is more complex, uses more energy, and can be slower than producing welded pipes from steel coils. This translates to a higher production cost.

Q9: Which pipe is easier to find in large diameters or very long lengths?

A: If you need really big pipes or incredibly long continuous sections, welded pipes often offer greater flexibility. The process of forming and welding steel plates allows for the creation of much larger diameters than current seamless manufacturing techniques typically permit. Similarly, coils of steel can be welded together to create very long pipe sections more easily than producing equivalent seamless lengths.

______________________________________________________________________________________________________________

🎯 Application Insights: When to Use Which?

Ultimately, the choice between seamless and welded pipes comes down to the specific demands of the job.

Q10: When is it best to choose a seamless pipe for a project?

A: Opt for seamless pipes when your project demands the utmost in reliability and safety, especially under challenging conditions. This includes:

- High-pressure applications: Think oil and gas pipelines, hydraulic cylinders, and chemical processing.

- High-temperature environments: Such as boilers, heat exchangers, and power plants.

- Corrosive service: Where the integrity of the pipe is critical to prevent leaks in harsh chemical environments.

- Structural integrity is paramount: Where uniform strength is non-negotiable.

Q11: When should I lean towards using a welded pipe?

A: Welded pipes are an excellent and often more economical choice for a vast range of applications where the extreme demands for seamless aren’t present. Consider welded pipes for:

- Low to medium pressure applications: Such as water pipelines, sewage systems, and general industrial fluid transfer.

- Cost-effectiveness: When budget is a significant consideration and the application doesn’t require seamless pipe’s specific advantages.

- Structural applications: Used extensively in construction for frameworks, handrails, and supports where load-bearing is key, but internal pressure is minimal.

- Large diameter requirements: When very wide pipes are needed for conveying large volumes of fluids at lower pressures.

The Verdict: No Single “Best” Pipe

As you can see, there’s no universal “better” pipe – only the right pipe for the right job! Seamless pipes offer superior integrity for the most demanding conditions, while welded pipes provide an economical and versatile solution for a multitude of other applications. Understanding these differences empowers you to make informed decisions for your projects, ensuring safety, efficiency, and cost-effectiveness.

We hope this deep dive into seamless and welded pipes has been enlightening! What other questions do you have? Let us know in the comments below!

Established in 1975, the Metallica Metals Group has its operations spread across major cities in India. We are a pioneer in the seamless as well as welded stainless steel pipes, carbon steel pipes, alloy steel pipes, stainless steel pipe fittings, carbon steel pipe fittings and alloy steel pipe fittings, with flanges manufacturing and processing industry. Our products are exported to over 70 countries across the world, while in India we have supplies to even the remote areas. With over 250 tons of sale in stainless steel and carbon steel pipes every day, Metallica has emerged as a prominent vendor for many buyers in India and Overseas.

Leave A Comment