🏗️ Seamless Vs Welded Pipe: Engineer’s Guide to Choosing the Right Type

When it comes to selecting the right steel pipe for your industrial application, understanding the difference between Seamless Vs Welded Pipe is critical. Whether you’re designing high-pressure systems or planning cost-effective infrastructure, the choice you make impacts performance, safety, and budget.

🔍 What is a Seamless Pipe?

A seamless pipe is manufactured without any welds or joints. It’s created by piercing a solid billet and elongating it into a hollow tube. This process ensures uniformity in structure and strength, making seamless pipes ideal for high-pressure, high-temperature environments such as oil & gas, petrochemicals, and power plants.

🔧 What is a Welded Pipe?

Welded pipes are formed by rolling steel plates or strips into a cylindrical shape and welding the seam longitudinally. These pipes are widely used in low to medium pressure applications like water supply, structural frameworks, and general engineering due to their affordability and availability in larger diameters.

🏭 How Are They Manufactured?

- Seamless Pipe: Produced via extrusion or rotary piercing, resulting in a pipe with no seam and consistent wall thickness.

- Welded Pipe: Made by bending steel strips and welding the seam, followed by heat treatment and quality testing.

📐 Characteristics & Benefits

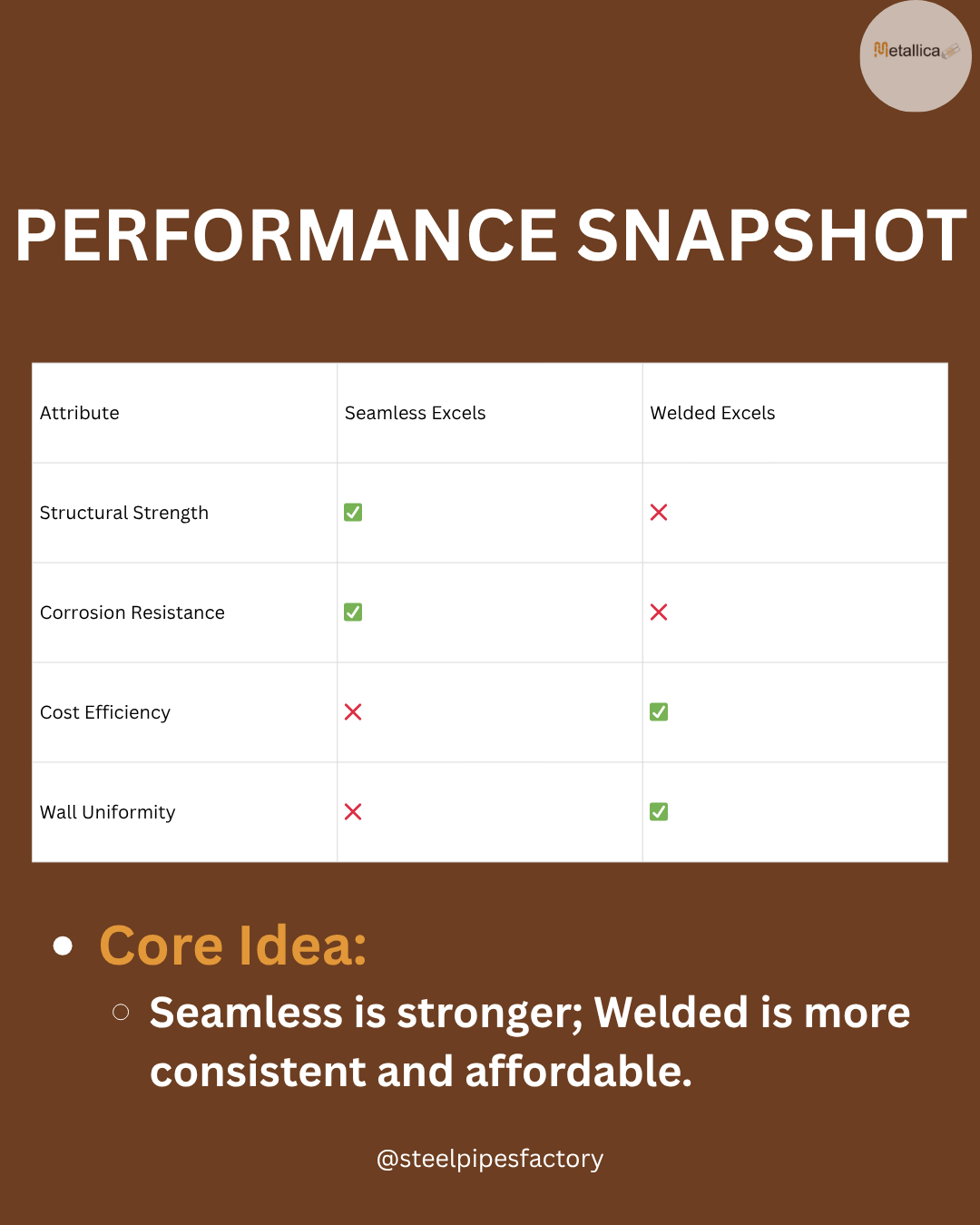

| Feature | Seamless Pipe | Welded Pipe |

|---|---|---|

| Structure | No seam, uniform wall thickness | Visible seam, may vary slightly |

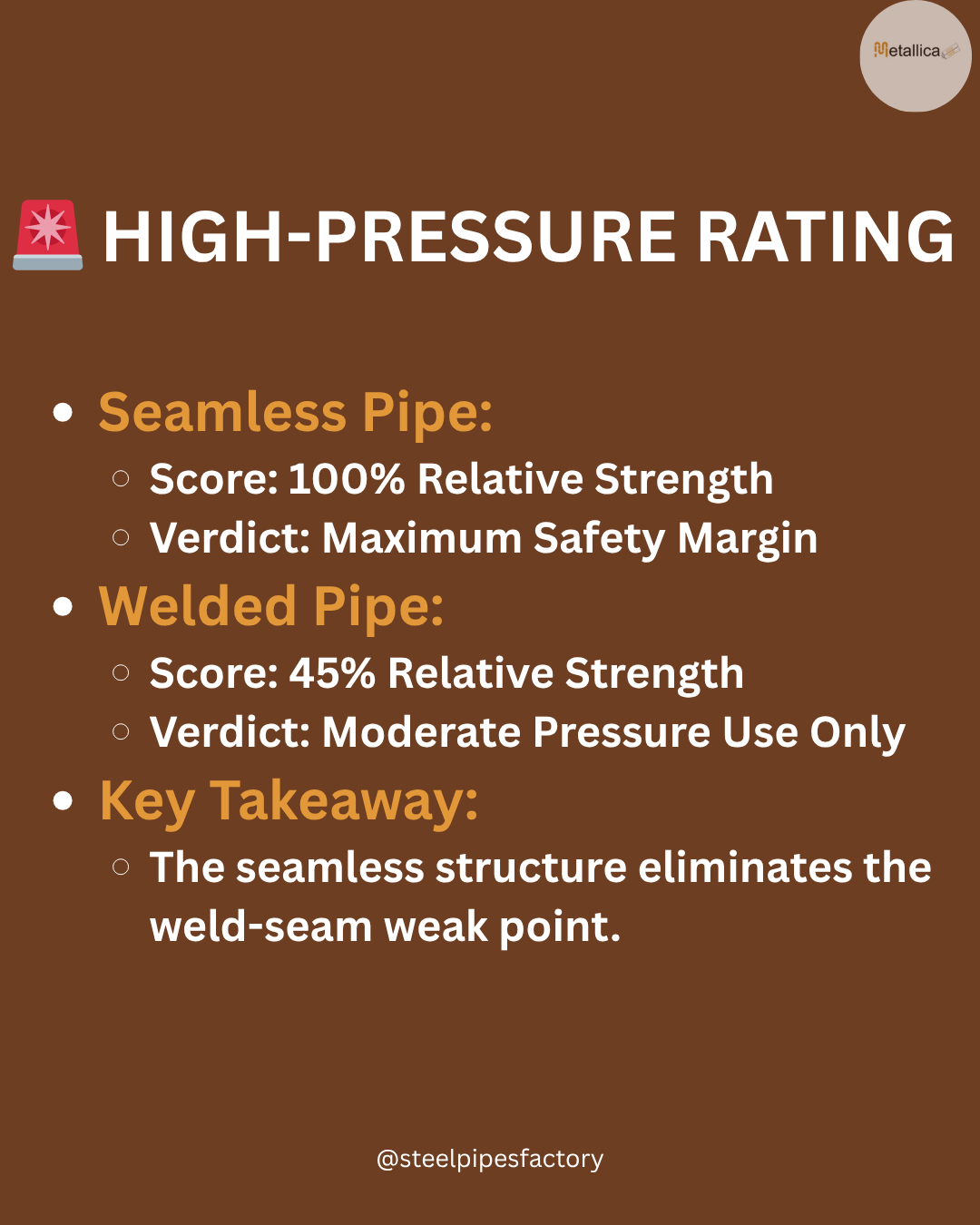

| Strength | Higher, suitable for critical systems | Adequate for standard applications |

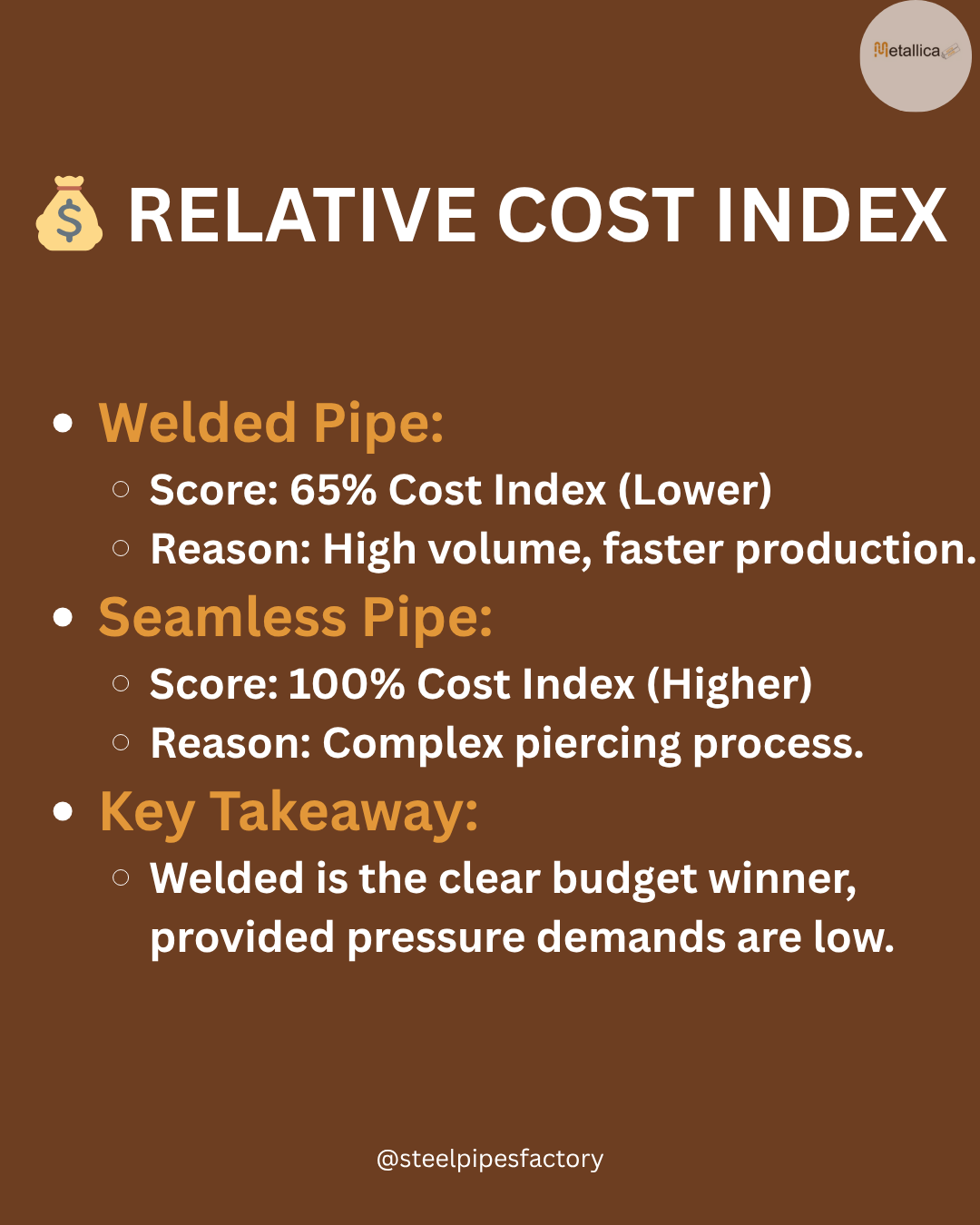

| Cost | Higher due to complex manufacturing | Lower, economical for large-scale use |

| Availability | Limited sizes | Wide range of diameters and lengths |

| Applications | High-pressure, corrosive environments | Structural, water transport, fabrication |

For More Details on Seamless and Welded Pipes, Click Here

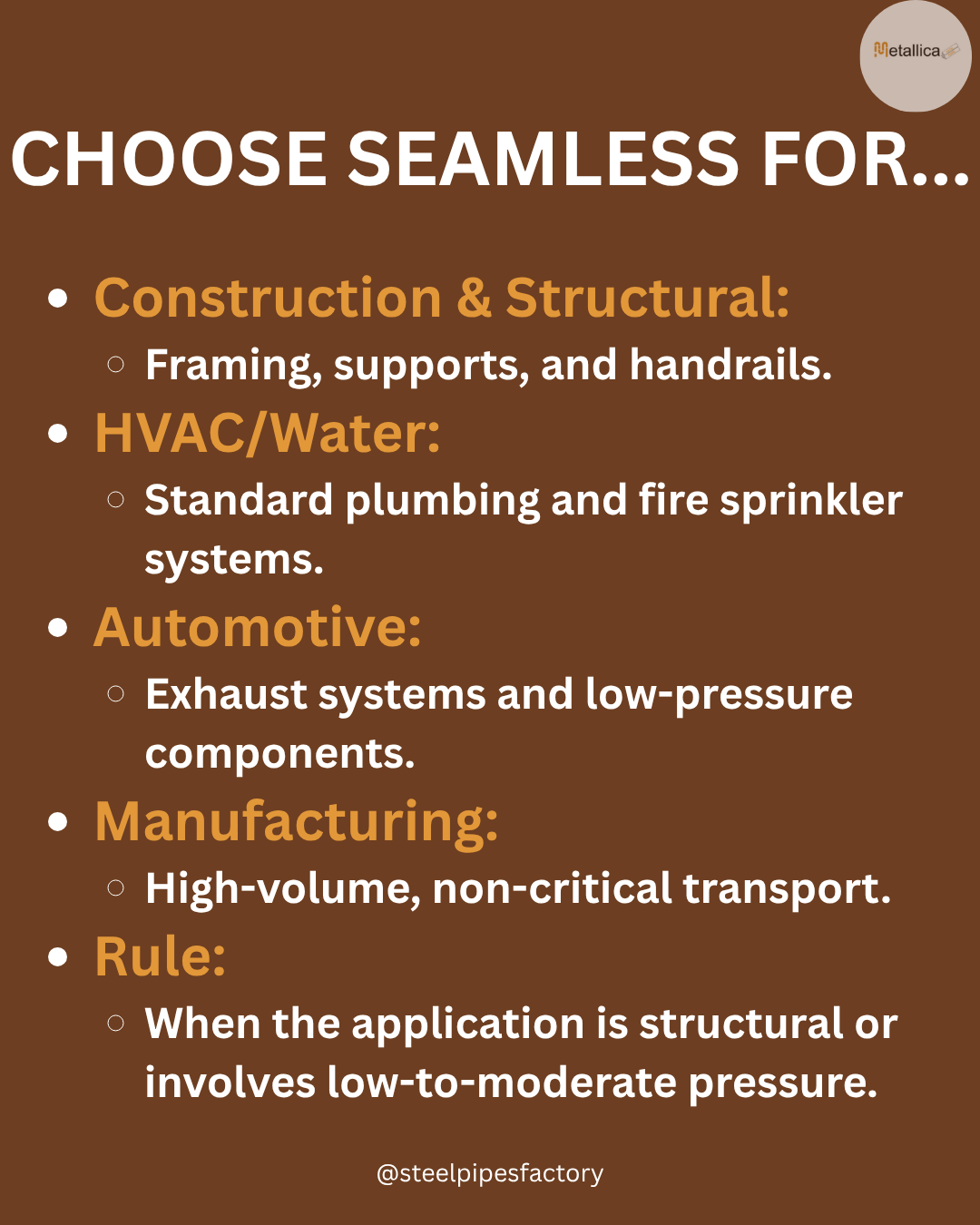

⚖️ Seamless Vs Welded Pipe: Which One Should You Choose?

Ask yourself:

- Is your system exposed to high pressure or temperature?

- Are you working with corrosive fluids or gases?

- Do you need precision and reliability over cost?

If the answer is yes to any of these, seamless pipes are your best bet. For budget-sensitive projects or non-critical applications, welded pipes offer excellent value and flexibility

Seamless Pipes

Welded Pipes

High Pressure Rating Of Seamless Pipes And Welded Pipes

Relative Cost Index Of Seamless Pipe And Welded Pipe

Performance Of Seamless Vs Welded Pipe

When To Choose Seamless Pipes

Seamless Pipe Vs Welded Pipe

Contact Us

Leave A Comment