Our general average selling price for stainless steel Super Duplex 2507 welded or erw pipes and tubes is Rs. 460/kg. The prices for Super Duplex 2507 welded pipes are lower compared to seamless pipes, as the cost of production is lower. SS Super Duplex 2507 welded pipes are made on a ERW tube mill from stainless steel Super Duplex 2507 strip coils formed into pipes through rolling and welding. Large size Super Duplex 2507 welded pipes, are fabricated from stainless steel Super Duplex 2507 plates, by roll forming and bending operation followed by welding.

- Our price list for SS Super Duplex 2507 seamless pipes and tubes – The prices are changing every week, and could be 4% up or down from the published prices. Please call us for the lowest price we can offer for you.

- If you are interested in purchasing high quality ss welded Super Duplex 2507 pipes, please contact us now for prices and product details. We guarantee lowest prices for stainless steel Super Duplex 2507 welded or erw pipes in India. Email Us on sales@metallicametals.com | Call Us On +918928722715

- Available on sale high quality stainless steel Super Duplex 2507 welded or erw pipes and tubes as per ASTM A312, ASTM A213, ASTM A249, ASTM A358 and ASTM A269 – Size Range of 1/8” to 24” (10.3mm to 610mm)

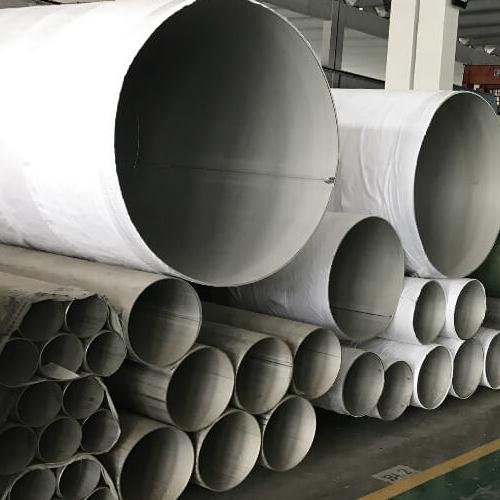

One of the largest manufacturer and supplier of SS Super Duplex 2507 welded pipes and tubes in India. SS Super Duplex 2507 welded pipes in standard sizes are available in stock for immediate deliveries in size range of 6mm OD upto 24″ OD in thickness upto 30mm. AISI Super Duplex 2507 stainless steel welded pipes are stocked in 6 MTR or custom lengths.

| Grade | Super Duplex 2507 |

| Type | Welded or ERW |

| Size | 6mm OD to 600 OD |

| Thickness | 1mm to 20mm |

| Specification | ASTM A213, ASTM A312, ASTM A249 |

| Application | Furnace, Kilns, Boilers, Heaters |

| Price (INR/Kg) | 450-475 |

| Delivery | 7-10 Days |