Request for Quote (RFQ Template / Specification Sheet For Tungsten Products)

This detailed template ensures you receive accurate, comparable quotes from every potential supplier.

| SECTION A: BUYER & PROJECT DETAILS | Information Required |

| Company Name: | |

| Contact Name & Role: | |

| Email & Phone: | |

| Project/Application: | |

| Required Delivery Date (or timeline): | |

| Final Delivery Location (City/State, India): | |

| Quote Submission Deadline: |

Click Here to read on How to choose tungsten products

| SECTION B: TUNGSTEN PRODUCT SPECIFICATIONS (Repeat for each line item) | Required Value / Selection |

| Product Form (e.g., Rod, Plate, Wire, Powder, Finished Part) | |

| Alloy Grade / Purity (e.g., Pure W $\geq 99.95\%$, W-Ni-Fe Class 3, W-Cu 80/20) | |

| International Standard (e.g., ASTM B777, AMS 7725E, DIN, or none) | |

| Quantity (Weight in $\text$ / Number of Pieces) | |

| Dimensions (mm/inches) | Length: |

| Width/Diameter: | |

| Thickness: | |

| Surface Finish (e.g., As Sintered, Ground, Polished) | |

| Specific Testing Requirements (e.g., Non-Magnetic Check, Radiographic Test, Hardness) |

Click Here to explore our Tungsten products

| SECTION C: QUOTATION REQUIREMENTS & TERMS | Response |

| Unit Price (INR per Kg/Piece) | |

| Total Material Price (Ex-Works) | |

| Mandatory Certification Fees (MTR, TPI – if applicable) | |

| Delivery Cost (To Final Delivery Location) | |

| Total FOR Site Price (All-inclusive Cost to your door) | |

| Minimum Order Quantity (MOQ) for this item: | |

| Guaranteed Lead Time (PO to Delivery): | |

| Payment Terms (e.g., 30% Advance, 70% against dispatch): | |

| Supplier Confirmation of Ex-Stock Availability? (Yes/No) |

Click Here to read Tungsten Material Grades & Standards

❓ Frequently Asked Questions (FAQs) about Tungsten Sourcing

Q1: What is the main difference between pure tungsten and tungsten alloy?

A: Pure tungsten is used where its extremely high melting point and electrical resistivity are critical (e.g., filaments, high-temperature furnace components). Tungsten alloys, primarily Tungsten Heavy Alloys (W-Ni-Fe or W-Ni-Cu) or Tungsten Carbide (WC), are blended with binders to improve machinability, ductility, and tensile strength, making them suitable for applications like radiation shielding, balance weights, and cutting tools. Your application dictates the necessary material.

Q2: Why is the density of tungsten so important, and how is it verified?

A: Tungsten's high density (approx 19.3gcm^3) is its defining characteristic for many applications, particularly counterweights, ballast, and radiation shielding. Density verifies the material's structural integrity and composition. It is verified using methods like Archimedes' principle or dimensional checks against the material's theoretical density, with the result explicitly noted on the Material Test Report (MTR).

Q3: How can I verify a tungsten supplier's quality certifications?

A: Always request copies of the supplier's ISO 9001:2015 (Quality Management System) certificate. More importantly, check the Material Test Report (MTR). Cross-reference the heat/lot number on the MTR with the physical markings on the material you receive. For critical materials, insist on a Third-Party Inspection (TPI) certificate from an accredited body like SGS, which independently verifies the material against the specified standard (e.g., ASTM).

Q4: Is tungsten sourcing from India affected by global 'Conflict Minerals' regulations?

A: While India is a consumer and processor, the global supply of raw tungsten ore is subject to "Conflict Minerals" regulations (like the U.S. Dodd-Frank Act) which aim to prevent the financing of armed groups. A reliable Indian supplier must have transparent procedures and documentation (Chain of Custody protocols) to confirm that their raw materials are sourced ethically and responsibly, ensuring they are not contributing to global conflicts or unethical labor practices.

Q5: What forms of tungsten does Metallica Metals supply in India?

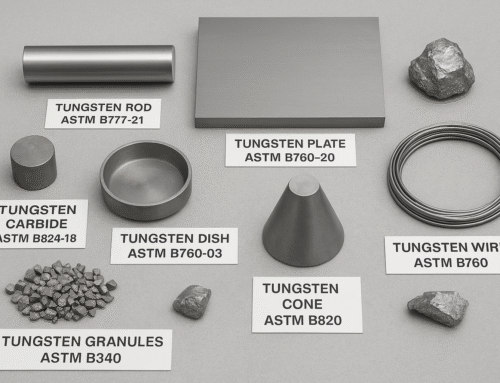

A: Metallica Metals is a major stockist and supplier of diverse tungsten products, including: Tungsten Rods and Bars, Tungsten Plates and Sheets, Tungsten Wire, Tungsten Heavy Alloy (W-Ni-Fe and W-Ni-Cu) for shielding and counterweights, and materials for specific applications like Tungsten Electrodes and Tungsten Copper alloys. We also cater to custom-machined components based on project drawings.

Established in 1975, the Metallica Metals Group has its operations spread across major cities in India. We are a pioneer in the seamless as well as welded stainless steel pipes, carbon steel pipes, alloy steel pipes, stainless steel pipe fittings, carbon steel pipe fittings and alloy steel pipe fittings, with flanges manufacturing and processing industry. Our products are exported to over 70 countries across the world, while in India we have supplies to even the remote areas. With over 250 tons of sale in stainless steel and carbon steel pipes every day, Metallica has emerged as a prominent vendor for many buyers in India and Overseas.

Leave A Comment