What is a Steel Pipe Mill Test Certificate (MTC) and Why is it Crucial?

If you’re sourcing industrial steel pipes, there’s one document that matters more than the price quote, more than the delivery schedule, and certainly more than the sales brochure. That document is the Mill Test Certificate, commonly known in the industry as an MTC.

Think of it this way: You wouldn’t buy a used car without checking its vehicle history report. You wouldn’t purchase pharmaceutical-grade chemicals without verifying their purity certificates. In the same way, you should never accept a shipment of steel pipes without thoroughly examining its steel pipe MTC.

This comprehensive guide will answer every question contractors, project managers, and procurement specialists typically ask about this critical document. By the end, you’ll understand not just what is MTC, but why it’s your most powerful tool for quality assurance and risk mitigation.

The Steel Pipe MTC Explained: Beyond the Paper

At its core, a mill test certificate is the material’s “birth certificate” and “passport” combined. It’s an official document issued by the steel mill’s quality department that provides verified evidence of the pipe’s chemical composition, mechanical properties, and manufacturing process.

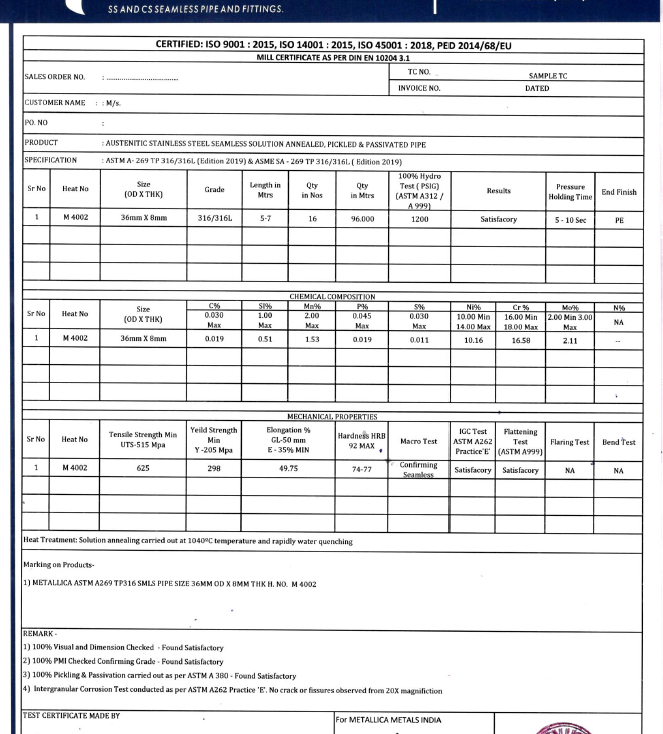

What Exactly Does an MTC Contain?

A proper mill test certificate is packed with technical data. Here’s what you’ll typically find:

- Header Information: Mill name, certificate number, date of issue, purchaser name, order number

- Material Description: Heat number (crucial for traceability), grade (ASTM A106, API 5L X52, etc.), dimensions (OD, WT, length), manufacturing process (seamless, ERW, SAW)

- Chemical Composition: Percentage of carbon (C), manganese (Mn), phosphorus (P), sulfur (S), silicon (Si), and other alloying elements

- Mechanical Properties: Yield strength, tensile strength, elongation percentage, hardness values

- Test Results: Hydrostatic test pressure, non-destructive test results (ultrasonic, eddy current)

- Standards Compliance: Confirmation that the material meets specified standards (e.g., “Conforms to ASTM A106 Grade B”)

- Authorized Signatures: Stamp and signature from the mill’s authorized inspector

Steel pipe Mill Test Certificate inspection at Metallica Metals quality control station

Why is the Mill Test Certificate So Crucial? The 5 Critical Reasons

- Quality Verification and Compliance

The MTC proves your pipes meet the exact specifications you ordered. This is non-negotiable for projects with strict regulatory requirements (oil & gas, nuclear, chemical plants).

- Material Traceability

Every pipe can be traced back to its original “heat” or batch of molten steel using the heat number. If a failure occurs years later, this traceability is invaluable for root cause analysis.

- Engineering Integrity Assurance

Design engineers calculate load capacities, pressure ratings, and safety factors based on specific material properties. The MTC provides the documented proof that these assumptions are valid.

- Risk Mitigation and Liability Protection

Accepting materials without an MTC transfers all quality risk to you, the buyer. With a proper certificate, liability remains with the mill and supplier.

- Welding and Fabrication Success

The chemical composition data (especially carbon equivalent) directly affects weldability. Without this information, your fabrication process could encounter serious issues.

MTC Checklist: Are You Getting a Valid Certificate?

Answer these questions before accepting any steel pipe shipment:

| Question | Why It Matters |

| ✅ Does the MTC have a valid heat/lot number? | Without this, traceability is impossible. |

| ✅ Do the chemical and mechanical properties match your ordered grade exactly? | Even slight deviations can impact performance. |

| ✅ Is the certificate on the mill’s original letterhead with official stamps? | Photocopies or “reissued” certificates raise red flags. |

| ✅ Are test results within acceptable ranges (not just “minimum” values)? | Materials barely meeting minimums may have quality issues. |

| ✅ Does the issuing mill match the pipe markings? | This confirms the document actually belongs to your material. |

Answering Your Top MTC Questions: A Contractor’s FAQ

Q1: “The supplier says the MTC is ‘included in the price.’ Is this negotiable?”

Answer: Absolutely not. A proper mill test certificate is not an optional add-on—it’s an integral part of the material itself. Any supplier suggesting otherwise should be immediately disqualified. At Metallica Metals, MTCs are standard with every shipment, no exceptions.

Q2: “What’s the difference between a 3.1 and 3.2 MTC?”

Answer: This refers to EN 10204 standards. A 3.1 certificate is a declaration of compliance from the mill without specific test results. A 3.2 certificate includes actual test results witnessed and verified by the mill’s independent inspection department. For critical applications, always insist on 3.2.

Q3: “Can I trust a ‘reissued’ or ‘reprinted’ MTC?”

Answer: Proceed with extreme caution. Only accept reissued certificates directly from the original mill, not from intermediaries. Request an explanation for why the original is unavailable.

Q4: “What if the pipe arrives without an MTC?”

Answer: Do not unload the truck. Immediately contact your supplier and place the material “on hold” until the proper documentation is provided. Document everything with photographs.

Q5: “How long should I keep MTCs on file?”

Answer: For the life of the structure plus applicable statutory periods (often 10+ years). These documents are part of your project’s permanent quality record.

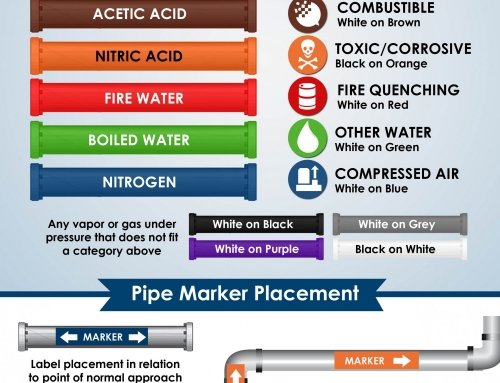

Image

The Hidden Cost of Accepting Materials Without Proper MTCs

Consider this real-world scenario: A contractor accepted a shipment of API 5L X52 pipes for a gas pipeline project without verifying the MTC. Six months after installation:

- A section failed during pressure testing

- The entire line had to be excavated

- The “supplier” had vanished

- Replacement costs exceeded $500,000

- Project delays stretched to 8 months

The initial “cost savings” of not insisting on proper documentation evaporated 100 times over. This is why understanding what is MTC and insisting on it isn’t just about paperwork—it’s about protecting your project, your budget, and your reputation.

Don’t Gamble With Your Project’s Integrity

In two decades of supplying steel pipes for everything from skyscrapers to subsea pipelines, we’ve seen it all. The single most consistent predictor of project success isn’t the lowest price—it’s the uncompromising commitment to quality documentation.

The Metallica Metals Promise: Every pipe we supply comes with its authentic, traceable, and complete Mill Test Certificate. Our quality assurance team verifies every MTC against the material before it leaves our yard, giving you double-layer protection.

Your Next Step is Simple but Critical:

Download our free, comprehensive guide: “SteelPipesFactory_MTC_Verification_Checklist_for_Contractors“– a step-by-step field guide to validating every certificate you receive.

Or better yet, work with a partner who handles quality so you don’t have to.

Request a Quote from Metallica Metals and receive not just competitive pricing, but the peace of mind that comes with fully documented, traceable materials. Our experts are ready to review your specifications and provide materials with impeccable documentation from world-renowned mills.

Remember: The quality of your documentation reflects the quality of your materials. Don’t settle for anything less than complete transparency.

Leave A Comment