Strategic Analysis of Sustainable Steel Procurement: Steel Suppliers and Green Certification Frameworks in the 2026 Market

The global industrial paradigm is currently navigating a definitive shift toward decarbonization, with the steel industry positioned at the center of this transformation. As a sector responsible for approximately 7% to 9% of global greenhouse gas emissions, the pressure to transition from traditional carbon-intensive manufacturing to sustainable, “green” processes has never been higher. The integration of green certifications—such as ResponsibleSteel, ISO 14001, and GreenPro—has become the primary mechanism through which the industry demonstrates its commitment to the Paris Agreement and environmental, social, and governance (ESG) standards. This report provides an exhaustive analysis of the sustainability frameworks currently governing the steel pipe and structural steel markets, and examines the technical innovations driving the future of low-embodied carbon materials.

The Architecture of Sustainability: Understanding Green Certifications

The movement toward sustainable steel is underpinned by a complex architecture of certifications that provide transparency and traceability across the supply chain. These standards allow stakeholders to distinguish between conventional products and those manufactured under rigorous environmental and ethical oversight.

1.The ResponsibleSteel International Standard

ResponsibleSteel stands as the preeminent global multi-stakeholder standard designed specifically for the steel value chain. Unlike general environmental certifications, it addresses the unique complexities of steelmaking, from raw material extraction to the final product. The certification is based on 13 fundamental principles that cover the entirety of the ESG spectrum.

The standard is not merely a checklist but a transformative framework. For instance, Principle 1 emphasizes Corporate Leadership, requiring that certified sites demonstrate a top-down commitment to ethical conduct and transparency. Principle 2 focuses on Social, Environmental, and Governance Management Systems, ensuring that sites have robust structures to achieve their stated objectives. As the industry moves toward 2030, the emphasis on Principle 10 (Climate Change and Greenhouse Gas Emissions) has intensified, requiring producers to align their operations with the global goal of limiting warming to 1.5 degrees Celsius.

The certification process involves rigorous third-party audits. A site first undergoes a self-assessment, followed by an external audit by approved bodies such as DNV or Bureau Veritas. These audits include worker interviews and site visits to ensure that policies are reflected in practice. Sites can achieve “Core Site Certification” and then progress to “Certified Steel” status, which adds requirements for the responsible sourcing of input materials and specific decarbonization thresholds.

2. ISO 14001 and the Environmental Management System (EMS)

While ResponsibleSteel is sector-specific, ISO 14001 remains the global baseline for environmental management. This international standard specifies the requirements for an EMS, allowing steel manufacturers and distributors to optimize resource use and minimize waste generation. For a steel supplier in Mumbai, ISO 14001 certification signals to the market that they have a systematic approach to identifying and controlling their environmental impact.

The implementation of an ISO 14001-compliant EMS typically leads to measurable improvements in energy efficiency and waste disposal. In the context of steel pipe manufacturing, this might involve the recovery of heat from welding processes or the systematic recycling of coolant fluids. Furthermore, the standard fosters a culture of continuous improvement, often referred to as the Plan-Do-Check-Act (PDCA) cycle, which is essential for maintaining competitiveness in a market subject to increasing regulatory scrutiny.

3. GreenPro: The Indian Benchmark for Product Sustainability

In the Indian market, the GreenPro certification, managed by the Confederation of Indian Industry (CII), has emerged as a critical tool for identifying sustainable construction materials. GreenPro is a Type-1 ecolabel that adopts a “cradle-to-cradle” approach, evaluating a product’s environmental footprint throughout its entire lifecycle.

For manufacturers of steel pipes and rebars, GreenPro certification involves a detailed assessment of raw material sourcing, manufacturing efficiency, and the product’s performance during its use phase. Products that receive this ecolabel are recognized by the Indian Green Building Council (IGBC) and contribute points toward green building ratings such as LEED. Tata Pipes and JSW Neosteel are notable examples of products that have successfully achieved this certification, providing builders with a clear choice for sustainable infrastructure.

Technological Drivers of Green Steel Production

The environmental impact of steel is primarily determined by the method of production and the energy sources utilized. The industry is currently witnessing a significant shift from traditional coal-based routes to more sustainable alternatives.

1. The Transition to Electric Arc Furnaces (EAF)

The primary technological lever for reducing the carbon intensity of steel is the adoption of the Electric Arc Furnace (EAF) route. Traditional Blast Furnace-Basic Oxygen Furnace (BF-BOF) production relies heavily on coking coal and iron ore, resulting in high carbon dioxide emissions. In contrast, the EAF process uses electricity to melt recycled steel scrap, which serves as its primary feedstock.

The environmental benefits of EAF steelmaking are profound. Nucor, a leader in EAF technology, reports that its process yields an average of 0.77 metric tons of CO2 per metric ton of steel produced, compared to the global average of 2.33 metric tons for the BF-BOF route. This reduction is further amplified when the electricity for the EAF is sourced from renewable energy, such as solar or wind power.

| Production Metric | BF-BOF Route | EAF Route |

| CO2 Intensity (Avg) | 2.33 tCO2/t steel | 0.77 tCO2/t steel |

| Recycled Content | Up to 30% | Up to 100% |

| Energy Source | Coal and Iron Ore | Electricity and Scrap |

| Environmental Impact | High-Embodied Carbon | Low-Embodied Carbon |

The carbon footprint of steel can be mathematically represented by its embodied carbon value (), which is the sum of emissions from extraction (), transportation (), and manufacturing (): where is the emission factor of the electricity grid and is the power consumed during production. As the grid decarbonizes, the of EAF steel will continue to drop, making it the superior choice for sustainable procurement.

2. Innovation in Steel Pipe Manufacturing: Hydrogen Transportation

A burgeoning area of innovation is the development of steel pipes designed specifically for the transportation of hydrogen. In January 2025, Tata Steel became the first Indian company to demonstrate end-to-end capabilities in this area, developing API X65 grade steel pipes compliant with the National Green Hydrogen Mission. These pipes are designed to transport 100% pure gaseous hydrogen under high pressure (100 bar). This development is critical because hydrogen is a key component of the global clean energy transition, and its efficient transportation requires specialized infrastructure to prevent material embrittlement and leakage.

3. The Circular Economy and Material Resilience

The sustainability of steel is not only defined by its production but by its role in the circular economy. Steel is the most recycled material on the planet, with structural steel containing an average of 92% recycled content. This circularity is a “cradle-to-cradle” process where decommissioned infrastructure—such as bridges and buildings—serves as the raw material for the next generation of products.

4. Recyclability and Strength Integrity

Unlike many other materials, steel does not lose its structural integrity during the recycling process. This allows it to be melted and reshaped multiple times without a drop in quality, a property that is essential for building long-lasting, sustainable structures. The use of recycled steel significantly decreases power consumption and raw material requirements, providing a greener alternative to carbon-heavy materials like concrete or timber from non-sustainable sources.

5. Waste Reduction through Pre-Engineered Solutions

Modern steel construction also focuses on waste reduction during the assembly phase. Pre-engineered steel components are fabricated off-site to exact specifications, which eliminates on-site cutting and material waste. This approach not only speeds up construction but also ensures that any excess material is captured at the factory level and immediately returned to the recycling stream.

Challenges in Sustainable Procurement: Navigating the Green Premium

Despite the clear benefits of green steel, procurement teams face significant challenges in operationalizing sustainable practices.

1.The Data Gap and Verification Barriers

A primary barrier is the lack of standardized, verifiable emissions data. While many producers make “green” claims, these are often based on self-declared figures or unverifiable averages. Procurement teams often lack the tools to compare offers based on carbon intensity, which leads to a continued focus on price and delivery terms alone. The industry is calling for more structured data and common standards to unlock green price signals and enable audit-ready documentation.

2. Understanding the Green Premium

The “green premium” refers to the higher upfront cost often associated with sustainable materials. This is driven by the investment required for EAF technology, renewable energy sourcing, and rigorous certification processes. However, this perception of higher cost is often a short-term view. Long-term savings are achievable through improved energy efficiency, reduced waste, and the mitigation of future carbon-related regulatory costs.

Metallica Metals: Expertise in High-Performance Steel Solutions

Metallica Metals (steelpipesfactory) is a prominent manufacturer and exporter of stainless steel pipes, tubes, carbon steel seamless pipes, tungsten pipes, welded pipes, industrial flanges, and specialty alloy products, headquartered in Mumbai. With over 50 years of manufacturing experience, Metallica has established itself as a trusted partner for the marine, oil and gas, and engineering sectors.

Product Expertise and Technical Compliance

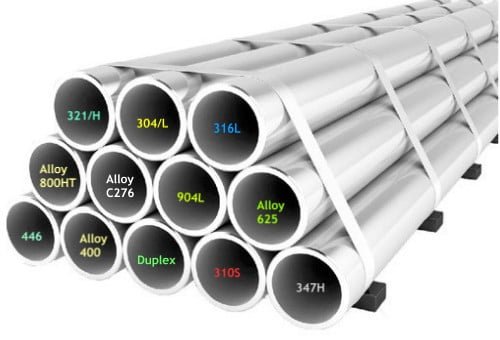

Metallica Metals manufacturing capabilities cover a wide range of seamless and welded pipes, buttweld fittings, including elbows, tees, reducers, and pipe bends. The company specializes in high-performance materials such as:

- Stainless Steel Grades: Including TP304/304L, TP316/316L, and high-temperature grades like TP321 and TP347.

- Nickel-Based Alloys: Specializing in Inconel 600, Monel 400, and Hastelloy C276 for highly corrosive environments.

- Chrome Moly Pipes: Essential for high-temperature service in power plants, including ASTM A335 grades P11, P22, and P91.

Commitment to Quality and Traceability

As an ISO 9001:2015 certified company, Metallica Metals prioritizes quality and transparency. All products are manufactured in compliance with international standards such as ASME, API, and EN. Key features of their quality promise include:

- 100% Traceability: All raw materials are sourced from reputed Indian and overseas mills and are fully traceable to the mill source.

- Rigorous Testing: Products are supplied with complete test certificates as per EN 10204 3.1 or 3.2, including 100% radiography test reports and third-party inspections from agencies like TUV and SGS.

- Replacement Guarantee: Metallica Metals offers a 100% free replacement guarantee on all products, reflecting their confidence in their manufacturing processes.

How Metallica Metals Supports Sustainable Infrastructure

Metallica Metals assists customers in achieving their sustainability goals by providing durable, high-quality components that extend the life of industrial facilities. Their ability to manufacture custom shapes and provide value-added services—such as electro-polishing and specialty coatings—ensures that projects are both economically and environmentally efficient. By maintaining a vast inventory of standard and odd sizes, Metallica Metals reduces lead times and minimizes the material waste associated with frequent emergency repairs.

Frequently Asked Questions (FAQs)

What are the primary benefits of choosing steel suppliers with green certifications?

Suppliers with green certifications like ResponsibleSteel or ISO 14001 provide independent verification that their products are manufactured with lower environmental impact and higher ethical standards. This helps buyers meet their own ESG goals, comply with tightening regulations, and reduce the embodied carbon of their projects.

How does the EAF production route contribute to sustainability?

The Electric Arc Furnace (EAF) route primarily uses recycled steel scrap and electricity, resulting in significantly lower carbon emissions compared to the traditional blast furnace route, which relies on coal. EAF steelmaking can reduce emissions by up to 75% depending on the source of electricity.

Is “green steel” more expensive than traditional steel?

While there may be a “green premium” or higher upfront cost due to newer technology and renewable energy usage, these materials offer long-term financial benefits. These include reduced maintenance, better durability, and avoidance of potential carbon taxes or penalties.

What is the significance of the GreenPro ecolabel in India?

GreenPro is a Type-1 ecolabel that assesses a product’s environmental impact across its entire lifecycle. In India, it is recognized by the Indian Green Building Council (IGBC) and helps construction projects earn points toward green building certifications like LEED.

Can steel pipes be used for hydrogen transportation?

Yes, but they must meet specific technical standards to handle high pressure and prevent embrittlement. Tata Steel has recently developed API X65 grade pipes that are compliant with hydrogen transportation requirements, marking a major milestone for India’s clean energy infrastructure.

How can I verify the sustainability claims of a steel supplier?

Buyers should request Environmental Product Declarations (EPDs), certification audit reports, and test certificates. ISO 14001, ResponsibleSteel, and GreenPro certifications provide credible, third-party verified evidence of a supplier’s environmental performance.

Does Metallica Metals offer certifications for its products?

Yes, Metallica Metals provides complete certification for its products, including ISO 9001:2015, and test reports as per EN 10204 3.1. They also offer reports from NABL-approved labs and third-party inspection reports for various projects.

Disclaimer:

This article is intended for informational and educational purposes only. The content has been compiled using information from web-based sources and does not constitute professional advice. Always consult appropriate experts or official sources for the most accurate and up-to-date information. *Images For Reference Purpose Only.

Leave A Comment