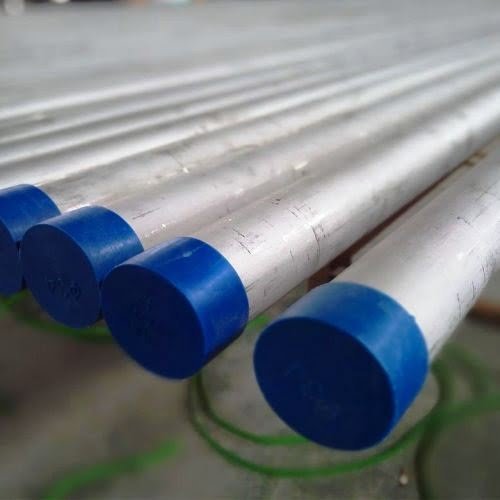

ASTM A53 Grade A, B Seamless and Welded Pipes Manufacturers & Suppliers

If you are interested in purchasing high quality ASTM A53 Grade A or Grade B black and hot-dipped, zinc-coated, welded and seamless steel pipe, please contact us now for more detailed information. Email Us on sales@metallicametals.com | Call Us On +918928722715

- Seamless and Welded ASTM A53 / A53M ASME SA53 Grade A, Grade B Steel Pipes Available for Sale in Size Range of 21.3mm to 219mm, with Wall Thickness: 1.8mm to 15mm

- Specification: ASTM A53 / A53M is the Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

- Mill test certificates will be issued according to EN10204.3.

Metallica is one of the largest manufacturer and supplier of ASTM A53 seamless and welded steel tubes in India. We offer ASTM A53 Grade A, ASTM A53 Grade B of types – S, E and F seamless and welded tubes in size range of 21.3mm to 219mm, with wall thickness: 1.8mm to 15mm in standard and custom lengths. As one of the most professional A53 seamless and welded steel tubes manufacturers and suppliers in India, we have one of the biggest steel pipe factory at your service. Metallica owns three warehouses, one factory and 3 offices mainly producing and marketing seamless carbon steel tube, alloy steel tube, seamless & welded stainless steel tube, as well as nickel alloy tubes.

Why Buy ASTM A53 Grade A, Grade B Seamless and Welded Steel Pipes from Metallica Metals?

- Large Scale Enterprise – Metallica is biggest stock holding, manufacturing and processing company of ASTM A53 Grade A, Grade B seamless and welded steel pipes in India. Our large volume production, sales and purchase enables us to offer our products at the most competitive prices in the industry.

- Testing of Steel Tubes – All ASTM A53 Grade A, B seamless and welded steel pipes are subjected to hydrostatic test, eddy current test, chemical and mechanical tests during the various stages of production.

- Marking & Packing of ASTM A53 Grade A, B Steel Tubes – Marking on all pipes is as per the predefined rules in the specification.

- Test Certificates & Inspection of A53 Grade A, B Steel Tubes – All our pipes are supplied with Mill test Reports, as per EN 10204 3.1. We can also allow third party inspection of all our products before delivery.

- We have our own QC team to control the quality to meet particular standard strictly.

- Short Lead Times – We can offer ASTM A53 carbon and alloy steel tubes with shortest delivery time.

- We can produce either standard or non-standard of the carbon and alloy steel tube.

Related Key Words: Asphalt Coated, Black Steel Pipes, Electric Resistance-Welded Steel Pipes, Furnace Butt-Welded Steel Pipes, Hot-Dip Galvanizing, Hot-Dip Process, Seamless Pipes And Tubes, Seamless Steel Pipes, Steel Pipes, Welded Pipes And Tubes, Welded Steel Pipes, Zinc Coated, Zinc-Coated Steel Pipes