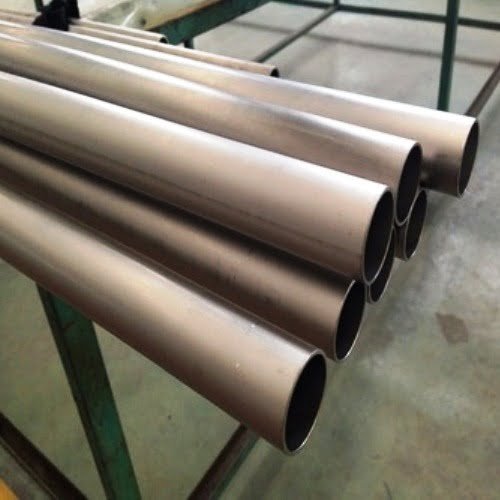

AISI 310S, 1.4845, UNS S31008 Stainless Steel Pipes & Tubes Dealers & Suppliers in Jamnagar, Gujarat

Single largest importer, trader, supplier and wholesaler of stainless steel 310 seamless pipes in Jamnagar, Gujarat, India. If you are interested in purchasing high quality stainless steel 310S seamless pipes in Jamnagar, please contact us now for prices and product details. Email Us on sales@metallicametals.com | Call Us On +918928722715

- Available on sale high quality stainless steel 310/310S seamless pipes in Jamnagar, Gujarat in size range of 1/8” to 24” (10.3mm to 610mm)

- Available on sale high quality stainless steel 310/310S welded pipes in Jamnagar, Gujarat in size range of 1/8” to 36” (10.3mm to 914mm)

Metallica is one of the largest manufacturers and suppliers of stainless steel 310S seamless and welded stainless steel pipes in Jamnagar, Gujarat, India. SS 310S stainless steel pipes (1.4845, UNS S31008) are delivered in annealed and pickled condition. Metallica stocks 310S stainless steel pipes in 20 ft or custom lengths in both welded and seamless forms. Metallica is one of the largest importer, trader, wholesaler and supplier of 310S stainless steel seamless pipes in Jamnagar, Gujarat, India.

Why Buy AISI 310S, 1.4845, UNS S31008 Stainless Steel Pipes from Metallica?

- Large Scale Enterprise – Metallica is biggest stock holding, manufacturing and processing company of 310S stainless steel pipes and tubes in India. Our large volume production, sales and purchase enables us to offer our products at the most competitive prices in the industry.

- Testing of Stainless Steel Tubes – All 310S stainless steel pipes supplied by Metallica are subjected to hydrostatic test, eddy current test, chemical and mechanical tests during the various stages of production.

- Marking & Packing of 310S Stainless Steel Pipes – Marking on all pipes is as per the predefined rules in the specification.

- Test Certificates & Inspection of TP310S Stainless Steel Pipes – All our pipes are supplied with Mill test Reports, as per EN 10204 3.1. We can also allow third party inspection of all our products before delivery.

- We have own QC team to control the quality to meet particular standard strictly

- Short Lead Times – We can offer ASTM A312 TP310S, 1.4845, UNS S31008 stainless steel tubes with shortest delivery time.

- We can produce either standard or non-standard of the stainless steel tube.

Related Key Words: ASTM A312 TP310S Seamless Pipes Dealers in Jamnagar, Gujarat, ASTM A312 TP310S Stainless Steel Seamless Tubes Suppliers in Jamnagar, Gujarat, Stainless Steel 310S Pipe Traders in Jamnagar, Gujarat, AISI 310S Seamless Pipes Traders in Jamnagar, Gujarat, 1.4845/UNS S31008 Seamless Pipes Suppliers in Jamnagar, 1.4845/UNS S31008 Tubes Dealers in Jamnagar